Second thermocouple daughterboard not recognized

-

Hi

I'm currently setting up Duet 2 Wifi for my Hangprinter. Today, I was trying to setup three thermocouples on two stacked daughterboards. First I had issues to get a temp reading from the second thermocouple that was connected to the first board.

As I'm working with Tobben's firmware, and the setup uses some of the expansion pins to control the ODrive boards, I suspected that it could be related to the non-standard setup.

So, I disconnected the ODrive cables and flashed the Duet with the latest v2.05 firmware. That helped me to get a reading from both thermocouple of the first board. The second board though remains silent. I only get the 2000deg reading.

Also, I switched the boards just to be sure they are both working, and they are. This is firmware/config related, but I'm not sure where to look.

Any hints?

-

Please provide your config.g file.

-

@dc42 Oh wow, I didn't expect a response that quick

I already left the lab, so I can't send you the config file at once, but I essentially used the Tobben's example config.

I already left the lab, so I can't send you the config file at once, but I essentially used the Tobben's example config.So, I'll try to quickly recreate the config settings based on Tobben's file:

; Configuration file for testing Duet Ethernet and Wifi

; Communication and general

M111 S0 ; Debug off

M550 PHP4Test ; Machine name and Netbios name (can be anything you like);*** If you have more than one Duet on your network, they must all have different MAC addresses, so change the last digits

M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0xED ; MAC Address;*** Networking - Enable for both WiFi and Ethernet boards.

M552 S1 ; Turn network on;*** Ethernet networking: Adjust the IP address and gateway in the following 2 lines to suit your network

M552 P192.168.1.14 ; (0 = DHCP)

M554 P192.168.1.255 ; Gateway

M553 P255.255.255.0 ; NetmaskM555 P2 ; Set output to look like Marlin

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves;;;; HANGPRINTER SPECIALS (M669, M666) BEGIN HERE ;;;;

; M669 K6 ; This is a Hangprinter enables ABCD-parameters in gcodes that refer to motors

; M584 A5 B6 C7 D8 P4 ; map ABCD-axes to ext driver pins (four visible)

; M584 E0:1:2:3:4 ; Regard all TMC2660s as extruder motor drivers

; M569 P0 S1 ; Drive 0 goes forwards

; M569 P1 S1 ; Drive 1 goes forwards

; M569 P2 S1 ; Drive 2 goes forwards

; M569 P3 S1 ; Drive 3 goes forwards

; M569 P4 S1 ; Drive 4 goes forwards

; M569 P5 S1 ; Drive 5 (A) goes forwards

; M569 P6 S0 ; Drive 6 (B) goes backwards

; M569 P7 S1 ; Drive 7 (C) goes forwards

; M569 P8 S0 ; Drive 8 (D) goes backwardsM669 P2000.0 ; Hangprinter printable radius (unused for now)

M669 S200 ; Hangprinter segments per second; Output of auto calibration script for Hangprinter

M669 A0.0:-1604.54:-114.08 B1312.51:1270.88:-162.19 C-1440.27:741.63:-161.23 D2345.00

M666 Q0.035619 R65.239:65.135:65.296:64.673; End of output auto calibration script for Hangprinter

; The following is assumed

; by the auto calibration script

; to be constant for all HP4s

M666 U2:2:2:2 ; Mechanical advantages on ABCD

M666 O1:1:1:1 ; Number of lines per spool

M666 L20:20:20:20 ; Motor gear teeth of ABCD axes

M666 H255:255:255:255 ; Spool gear teeth of ABCD axes; Adjust the following to match your ODrive settings

M666 J25:25:25:25 ; Full steps per ABCD motor revolutionM208 Z2309.54 ; set maximum Z at D anchor. See M669 ... D<number>

; Use

; M564 S0

; If you don't want G0/G1 moves to be be limited to a software defined volume;M569 P5 I"0x0a" ; i2c addresses set up, but will probably not be used on HP4

;M569 P6 I"0x0b"

;M569 P7 I"0x0c"

;M569 P8 I"0x0d"; Connect ODrive 0 to Serial device 1 at 115200 baud

; M569 Q0:1:115200

; Connect ODrive 1 to Serial device 99 at 115200 baud

; M569 Q1:99:115200

; Device 99 is the two middle pins on DuetWifi's SPIO header

; (sometimes called Temp Daughterboard header)

; The special number 99 is used because this serial device

; is special. It's really meant to be used for

; SPI communication with temp daughterboards and such.

; MOSI = TX (Connects to ODrive's RX)

; MISO = RX (Connects to ODrive's TX)

; Look for SPI0_MISO and SPI0_MOSI on DuetWifi wiring diagramM201 X10000 Y10000 Z10000 E1000 ; Accelerations (mm/s^2)

M203 X36000 Y36000 Z36000 E3600 ; Maximum speeds (mm/min)M574 X2 Y2 Z2 S1 ; set endstop configuration (all endstops at high end, active high)

M906 X1200 Y1200 Z1200 E1400 I60 ; Set motor currents (mA) and increase idle current to 60%

M566 X1200 Y1200 Z1200 E1200 ; Maximum instant speed changes mm/minute; Thermistors & thermocouples

M305 P0 T100000 B3950 R4700 H30 L0 ; Put your own H and/or L values here to set the bed thermistor ADC correction

M305 P1 X100

M305 P2 X101

M305 P3 X102M570 S180 ; Hot end may be a little slow to heat up so allow it 180 seconds

; Adjustments for J-heads used as dummy heaters on test rig

M307 H0 A250 C140 D5.5 B1Super Volcano 80W 24V

; M307 H1 A1271.9 C432.5 D8.2 B0

; M307 H2 A250 C140 D5.5 B0

; Tool definitions

M563 P0 D0 H1:2:3 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperaturesM92 E415 ; Set extruder steps per mm

M208 S1 Z-10.0 ; set minimum Z

T0 ; select first hot end

; Enable Fan 1,2 & 3 thermostatic mode for heater 1 (E0 HEAT) at 45 degrees

M106 P2 X150 T45 H1:2:3 -

I haven't found a solution yet. Any ideas?

-

@atmark I have the same problem although my arrangement is a little different.

I am using thermistor for bed.

PT100 daughter board for extruder heater.

Thermocouple daughter board plugged into PT100 board piggy back.

No response from thermocouple board, not even 2000’C. Just ignores it.

I am using duet firmware v2.05.

I’m sure it worked before with earlier versions.

I want to display chamber temp using thermocouple board.I will post full details and config file once all the Christmas celebrations are over and I’ve sobered up

-

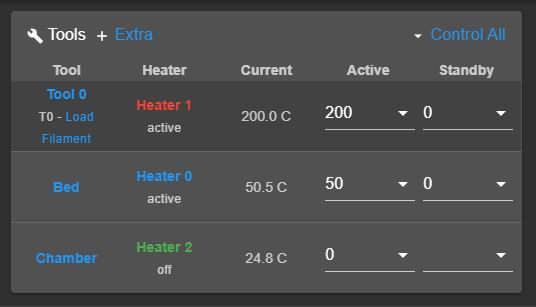

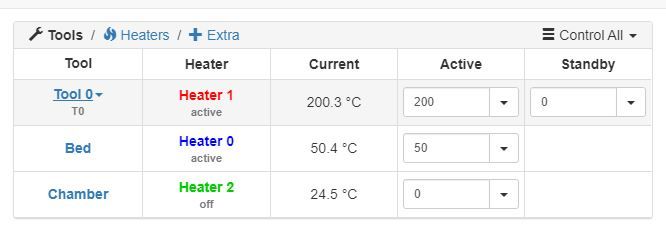

It's working fine now, I had forgoten to put the M141 command in config.

https://duet3d.dozuki.com/Wiki/Gcode#Section_M141_Set_Chamber_Temperature_Fast

So I have

M141 H2

M305 P2 X102

in my config.gFirmware is 2.05

-

@atmark Can you check which version of the thermocouple daughter boards you have? The older boards are MAX31855-based, the newer ones are MAX31856-based. This will change the M305 assignment. As it says https://duet3d.dozuki.com/Wiki/Connecting_thermocouples#Section_Duet_2_WiFi_Ethernet_and_Maestro

If your daughter board uses MAX31855 chips then the terminal blocks labelled 1 and 2 on the lower daughter board will be temperature measurement channels 100 and 101 respectively. If you stack two daughter boards, the terminal blocks on the upper board will be channels 102 and 103.

If your daughter board has two LEDs labelled FAULT then it uses MAX31856 chips. In this case the terminal blocks labelled 1 and 2 on the lower daughter board will be temperature measurement channels 150 and 151 respectively. If you stack two daughter boards, the terminal blocks on the upper board will be channels 152 and 153.

If you've got newer boards, and your config.g should be set up as:

M305 P1 X150 M305 P2 X151 M305 P3 X152Though I did test this (I only have a PT100 daughterboard and a newer thermocouple board stacked on top), using X101 did report 2000C temps. So I'm not quite sure what's going on with your setup.

Lastly, make sure there is a comment mark

;before "Super Volcano 80W 24V" in your config.g. This should be ignored, but just in case it's causing problems, put it in.Ian