Maestro Layer Shifting

-

Hey Guys,

Ever since I upgraded my Anet A8 with a brand new genuine Duet Maestro Board I've got a problem with layer-shifting, mostly in the y axis, in both directions and never at the same heights.

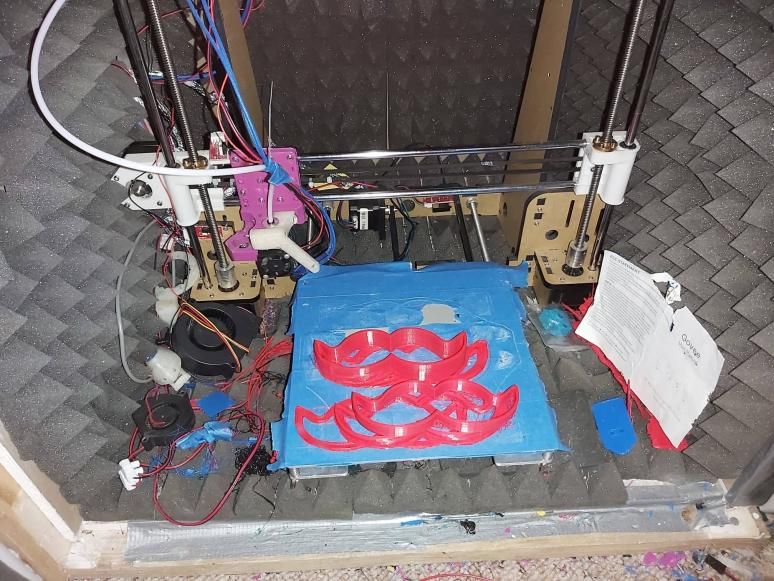

Lately it has become so bad I can't use it at all anymore. I checked the entire Frame and I can't find any mechanical issues. I've tightened the (new) belts as well as I can, given that I run a printed carriage for the V6 Hotend with a Titan Extruder as a bowden setup. I even swapped all endstop sensors for new ones and have wrapped those cables in aluminium foil, in the hope that that will prevent signal interferences.My Camera isn't the best, as is my cable management. The lower one was a previous try and the upper my most recent one. If you need some more detailed pics I can provide.

The extruder is the "special" motor you can get with the Titan extruder, the rest are the standard A8 ones.

I'm kinda running out of ideas and am really fed up with that piece of crap, I never got any good quality pieces and I am almost at the point where I want to switch back to stock, if it weren't for the whole catching-fire thing Anet have going on.

Attached is the config file from the board, you are probably smarter then I am and can figure out if there are any problems.

Please help

config(1).g

-

Would be odd if it was due to the board. Have you observed the shifts? any noises?

I'd start by ruling out collisions with the printed part.

-

… if it weren't for the whole catching-fire thing Anet have going on.

Good intent, but then, why the hell do you put all the foam around your A8? That’s a really innovative way to build a BBQ charcoal lighter.

And PLEASE clean up your cabling: flying wires from the bed across the Y stepper (i.e. in the neighbourhood of moving parts) increase the fire hazard considerably.

-

As bearer said, that is most likely a collision with something (not only the printed part). It could also be a tight spot and insufficient motor torque ... or just insufficient torque period.

Insufficient torque could be due to low voltage (leads to the motors too thin or too long), bad connections, attempts at printing too fast and there are likely more causes..I would suggest a serious cleanup of the whole setup as the problem could be staring you in the face but you might not see it with all the 'stuff' all over the place.

Plant yourself in front of the printer as it's doing it's thing and watch it like a hawk!

Most of my layer shifting problems were caused by interference with wires so make sure everything is well routed and zip tied down so it can't vibrate or move and somehow obstruct the works.

Remove anything from the printer enclosure that isn't part of the current print - fans, wires, print samples, pieces of paper. The wiring to the central motor in the back (or possibly endstop wiring) looks like it's just asking to grab things.

Take some more pictures after you have cleaned up especially around the left side where there is all the wiring.

-

I am not familiar with this printer and the stepper motor current requirements ( X / Y) but they seem a bit low for anything I have ever seen (all two printers

)

) -

Using stealthChop mode at higher speeds can cause layer shifts. When the nozzle hits a blob or curl up, in stealthChop mode the drivers can't adapt immediately to the increased load. If you have increased the maximum stealthChop speed using M569, go back to the default. If you haven't, then try switching the drivers into spreadCycle mode using M569. If that still doesn't solve it, perhaps you have set the motor current too low.

-

M305 P0 T100000 B3950 C7.06e-8 R4700 ; Set thermistor + ADC parameters for heater 0

M305 P1 T100000 B4725 C0 R2200 ; Set thermistor + ADC parameters for heater 1Your thermistors are configured wrong.

Duet Maestro uses R2200 not R4700

Its either (B4725 and C7.06e-8) or B3950 and C0. you got them mixed.

also your steps seem odd for a anet a8

M92 X95.68 Y95.14

normal for an anet is 100