Hangprinter help on duet 3

-

We got it set up briefly to demonstrate the concept.

And had to tear down again to move locations. It was never intended to print at this spot.But we got all axis moving and the correct amount of feed on each roll and the extruder. Something was a bit off with the calibration because as it moved some lines would end up with more tension and eventually skip steps or cause other lines to get slack.

On the config are the anchor points measured from the nozzle 0,0 to the center between the pulleys or from the corners on the A/X side to the closer pulley on the anchors?

We are hoping to get printing next time we get it setup.

Thanks

-

AFAIR, in the configuration X0 Y0 is the position below the D anchor.

Have you read https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareHangprinter ?

-

@dc42 said in Hangprinter help on duet 3:

AFAIR, in the configuration X0 Y0 is the position below the D anchor.

Have you read https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareHangprinter ?

Yep I've gone through it many times and other hangprinter build guides. I haven't yet gone through the whole thread on the reprap forum, but I'm working on it. I'll draw a picture to better ask my question.

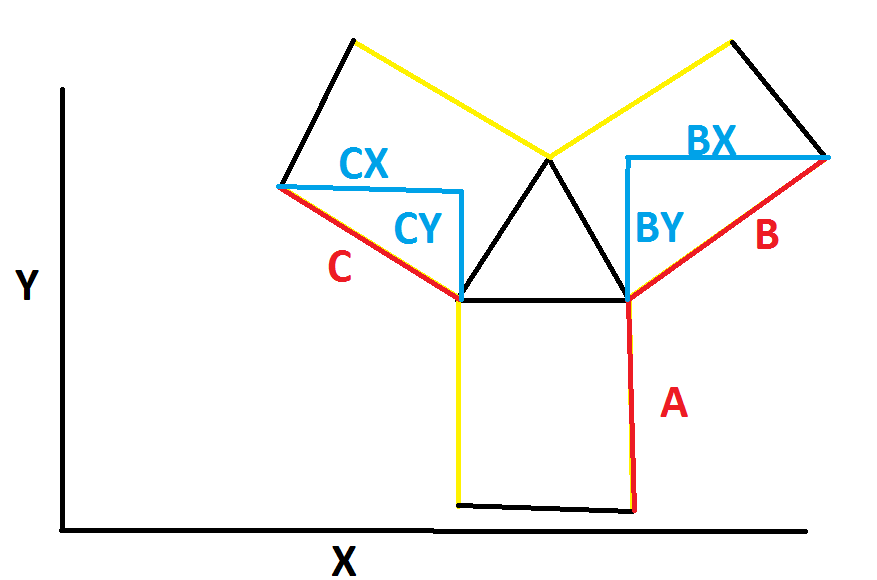

My under standing is that in Marlin the config is like this:

Where the anchors are measured from the string connection points on the corners of the frame.Does the reprap config work the same or is it more like this:

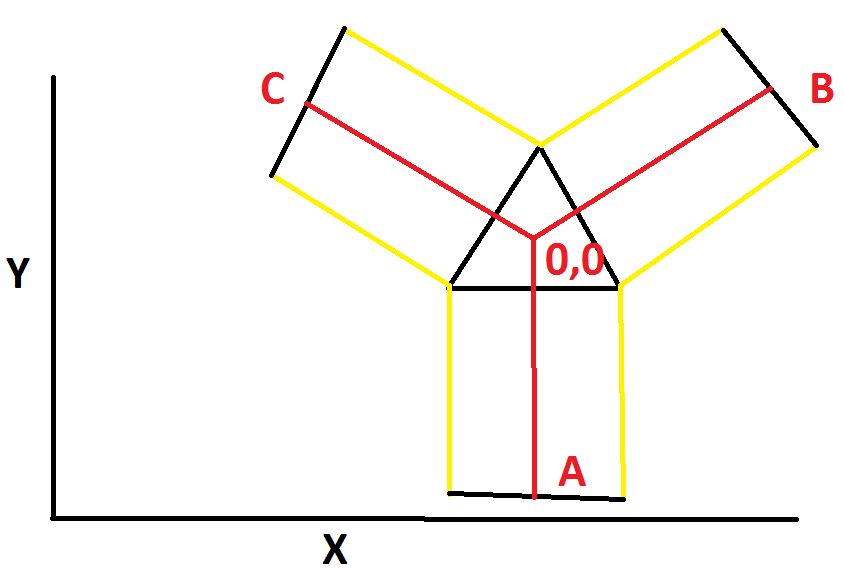

Where 0,0 is the tip of the nozzle and the red lines are reference for the anchors.

Thanks

-

@Shinomori said in Hangprinter help on duet 3:

Does the reprap config work the same or is it more like this:

Where 0,0 is the tip of the nozzle and the red lines are reference for the anchors.

It's like your second diagram, where (0,0) is the position right below the D anchor. Calling 0,0 the position of the nozzle doesn't make sense, because the nozzle moves.

-

Hey, i am working hard to get my Hangprinter working too and doing it with Duet 2 firmware. Neithertheless i figured out that the offical documentations lacks information about the M669 command and it's configuration parameters to use

https://duet3d.dozuki.com/Wiki/Gcode#Section_M669_Set_kinematics_type_and_kinematics_parameters

There is a huge line in config.g (can also be forced to generate by M500 command which write config_override.g). This looks like M669 K6 A0.000:-2000.000:-100.000 B2000.000:1000.000:-100.000 C-2000.000:1000.000:-100.000 D3000.000 P2000.0 Q0.007000 R55.000:55.000:55.000:55.000

ABCD are the anchor point locations

But what are P, Q and R values?

cheers, Mario

-

P is the print radius. I don't know what Q and R are because they are not supported by the standard firmware. I guess the creator of Hangprinter added them in his fork. Possibly something to do with spool build-up compensation. Best ask him.

-

Hi,

finally our printing is working and documentation for a lot of stuff can be found here > https://wiki.fablabchemnitz.de/display/TH

We did not use Duet 3 firmware but there you can find different topics about things like motor wiring, math, coordinate system, PID tuning, etc.

-

I'm glad you got it working!

I presume you used the RRF firmware fork from the creator of Hangprinter. We'd love to incorporate many of the improvements he has made to Hangprinter support in that fork into our standard build. Unfortunately, in that fork he repurposes the UARTs (to drive Mechaduinos in torque mode AFAIR), which makes it incompatible with normal use of RRF.

Duet/RRF do support I2C, so I don't know why I2C wasn't used. However, i2C is generally a bad choice for connecting different devices because it has no noise immunity. It was designed for interconnecting ICs on the same board only.

-

undefined o_lampe referenced this topic

undefined o_lampe referenced this topic

-

@dc42 With the newly implemented torque mode in RRF3.5, does that mean we can use hangprinter kinematic in torque mode soon?

Or is it a different thing? -

@o_lampe RRF already supported torque mode for Hangprinter version 4, which uses O-drives. It may be that in future it will be possible to use Duet3D closed loop drivers instead of O-Drives in a Hangprinter.