Connecting Duet 3 Main board to HY 2.2kw VFD

-

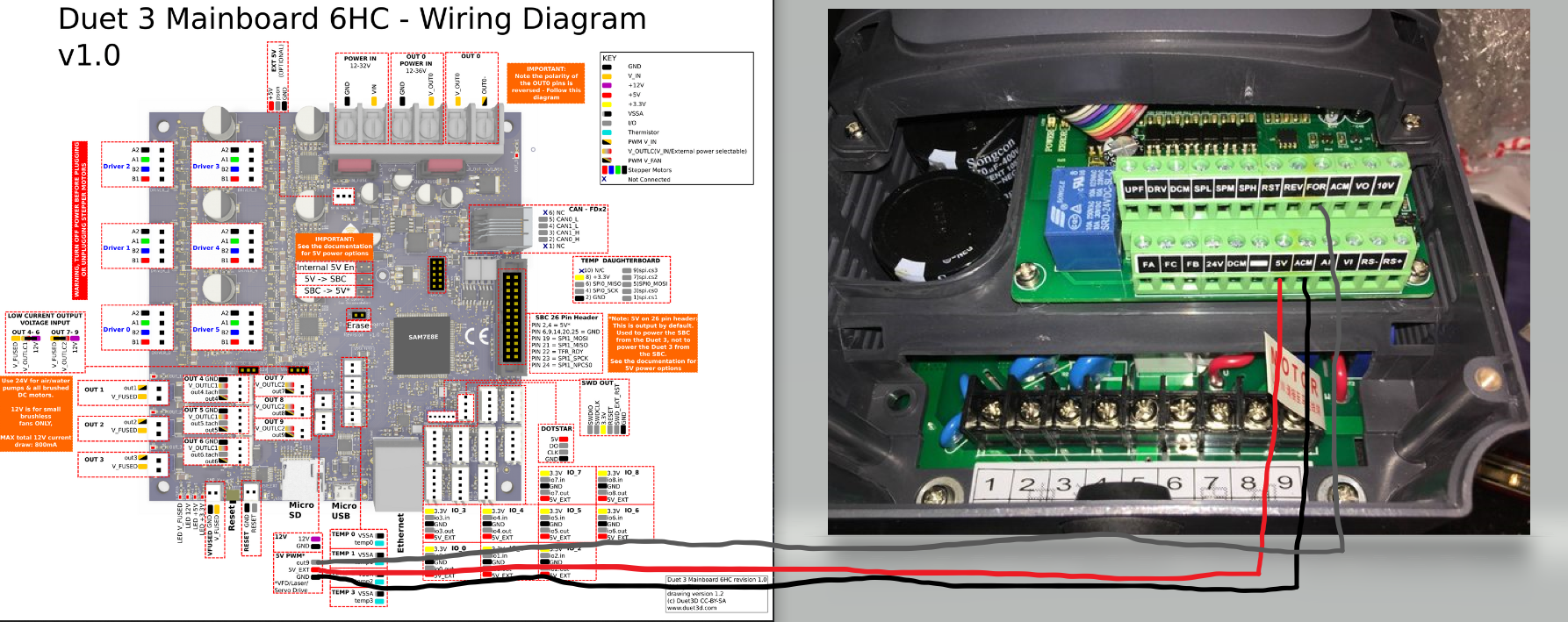

I am getting ready to connect my Duet 3 to a HY 2.2kw VFD. Can someone tell me if the connections in the picture are correct and if not which ones are?

-

Ground and PWM to "FOR" look OK-ish.

Not sure about 5V. ON the VFD, is that an input? or an output?

-

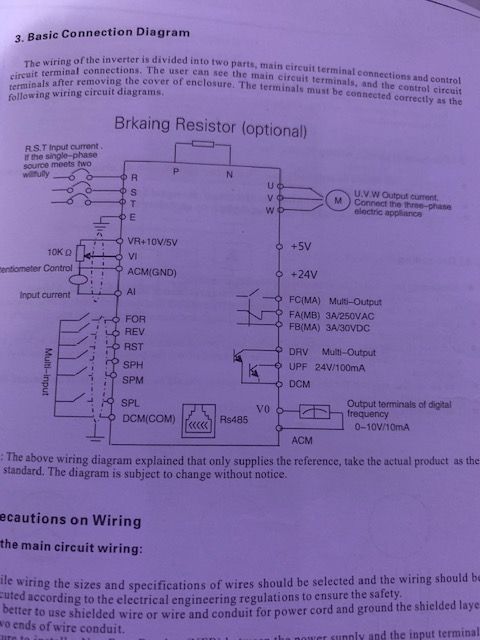

@Danal I cant find anything that clearly states in their manual but based on the only page that even shows the 5V it seems to be an output

-

Were it me, I start with ground and PWM connected and see if various M commands make it run.

-

@Danal Ok I dont actually have the cable yet to install it but as soon as it arrives I will try that. Just wanted to be ready for when it does.

-

May I inquire as to what exactly you are wanting to achieve here ?

At minimum I believe that both 5V connecting points are outputs and it is unlikely that connecting them together is a good thing.

YMMV -

@jens55 I’m trying to both be able to turn on and control my spindle speed with my duet 3

-

I suspect (note that I only suspect and not know) that you will need to connect your ground line to DCM and your PWM output to FOR. The PWM output can not be used as PWM but needs to be configured as on or off (and I can't give details on that). All you will achieve in that configuration is to turn the VFD on or off. I would actually advise against that sort of arrangement and would use a relay in between the Duet and the VFD. In that configuration you would drive the relay (with a flyback diode) with the PWM output (still only configured as an on/off output) and ground on the Duet. The contact on the relay will connect to DCM and FOR on the VFD.

This should turn the VFD on and off but will not allow rotational direction which is presumably not needed.

Speed will require a DC voltage between ACM and VI or a current source between ACM and AI. The schematic you posted suggests a resistor setup with the wiper connected to VI and the legs connected between VR and ACM. There is insufficient information on how to drive this with the Duet. About the only thing I can suggest would be to use a servo to drive a 10k resistor but that seems very ass backwards and I am sure that there are better ways which should be described in the complete manual.

Please note that this information is strictly based on my best guess and should not be relied on for anything. Use this only as a second opinion, do your research and make up your own mind. -

@jens55 Wow that is some other language info. Ill have to read this a few times and go through that step by step just to try and understand it. I thank you though, It is much appreciated

-

One other tidbit that just occurred to me ... this is based on a VFD that runs a dust collector at my house. I have a pot as a speed adjustment control, similar to what your diagram looked like.

When reducing speed via that pot, it is very easy to fault out the VFD if you reduce the speed faster than the motor can follow. You can't have the Duet set speed at let's say 2000 RPM and then command a speed change to 1000 RPM.

Your VFD may not have the sensors needed to sense the discrepancy between actual speed and set speed. You might need to install a braking resistor (which I don't use) to get appropriate braking, You might make a policy of not doing any downward speed change while the motor is running. Heck, your application might not even need a reduction in speed while it is running so maybe it won't make a difference. I just thought that you should be aware of that possibility. -

@jens55 I think I might be getting over my head. At this point its just a really cool hobby so adjusting the speed on the VFD before I start a cut and turning it off might be an easier task. I was just hoping that once I was linked to the Duet ince I implemented my gcode it would automatically deal with the speeds and such. Not a big deal either way. Thank you though for all the info

-

My intent was not to discourage you but to give you some things to think about. I do agree though that speed could probably be dealt with manually until you are ready to dive a bit deeper. The concept of turning the VFD on and off under duet control is very easily implemented and can be done in little steps by first implementing the control manually with a remote (to the VFD) switch and then replacing the switch with a relay.

Depending on what you are running with the VFD, speed control might not be that critical anyhow. If, for example, you are running a router spindle, you should be able to do the vast majority of cuts with a single set speed.Further thought: I noticed these inputs .., SPH,SPM,SPL. I am thinking that these could be for 'speed high','speed medium' and 'speed low'. If that is in fact true then you might not even need direct speed control. They could be pre-settable speeds and you could then implement 3 different speeds with just relay control. It might even turn out that those lines are a binary input in which case it could be 7 preset speeds. Something to explore if you don't need true variable speed!

-

Yeah, the more I look at the schematic of the VFD, the more I see the things that Jens is talking about. I'd put the VFD on a bench and play with it for quite a while, via some switches, and potentiometer and etc, before I ever tried the Duet.

Having said that, I believe that on/off and speed are going to be fairly easy, once you've played with it on the bench.

-

@Danal @jens55

I found another forum where a gentleman is hooking up a 110v VFD. Im guessing its along the same lines but he adds an anaolog converter to get the 10v. https://openbuilds.com/threads/workbee-cnc-w-duet2-and-chinese-spindle-control.14004/ -

@jens55 just looking at the manual for the VFD and yes the SPH, SPM and SPL are high medium and low speeds