Delta effector tilt and mesh bed leveling

-

My towers are the same distance from each other top and bottom on all 3 sides. Same value on all 6.

Each tower is square to the bed (using a 24" x 16" square).

The effector is perfectly parallel to the bed in the center but tilts back and forth when approaching the towers and traveling away from the towers.

Bearing spacing is 3.72" +-.003 for all 6 measurements.

How do you reduce/get rid of this?

Each arm is a carbon fiber rod with an aluminum rod end and an IGUS bearing built to 440mm +- .05mm preloaded with no play.

My carriages are roller wheels on the inner powdercoated extrusions on the towers. Not best but I can't invest in a IGUS linear rail system right now.

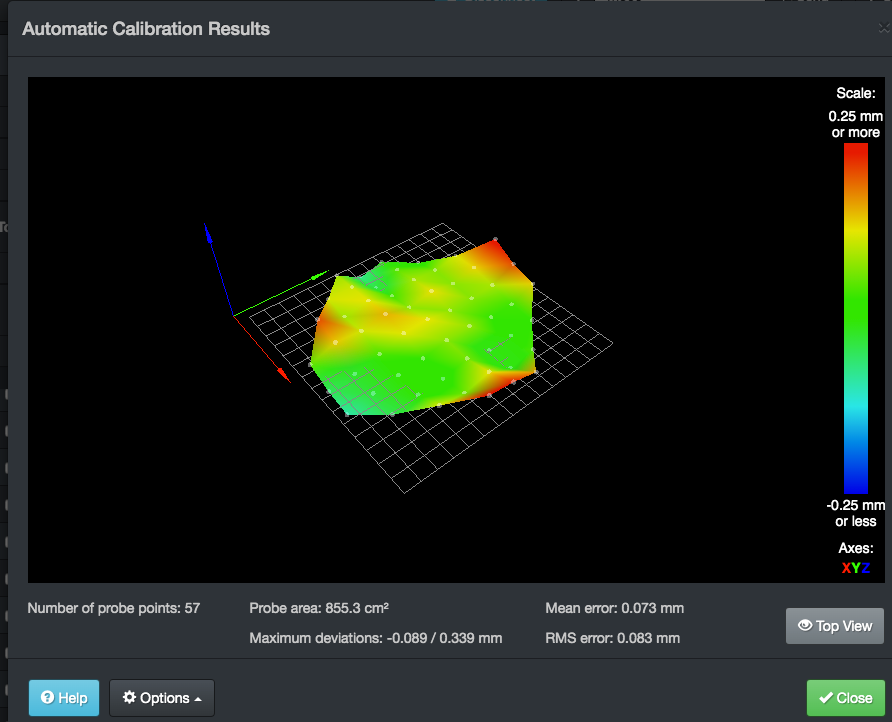

Not quite sure what else I can do to reduce deviation. Every time I run mesh bed compensation the max deviation comes out to something else.

Also, My first layer test is coming out very inconsistent. Perfect in some areas, too high in others,

-

What probe are you using. Everything needs to be square, the holes on the carriages need to be exactly as far apart as they are on the effector. The left hole needs to be the exact height as the right hole on both the carriage and the effector (ie the carriage isn't rotated) there's a lot of things that cause tilt

-

@gperman said in Delta effector tilt and mesh bed leveling:

tilts back and forth when approaching the towers and traveling away from the towers

Deltas are EXTREMELY sensitive to this; it really must be fixed before going further.

If the tilt is totally consistent, it indicates a geometry problem. Most common is that the spacing "between" the two arms at a given single carriage does not match the spacing of those same too arms at the effector. One classic cause for this is placing a spring between the arms to pre-load play out of the rod ends. Absolutely do not do that.

There are some other possible geometry problems. Can you post a few pictures of the printer itself, taken from different distances and angles?

If the tilt is either inconsistent, and/or specifically varies depending on effector motion TO vs FROM the tower, that is an indicator of play. You just have to find and correct that.

-

@Danal said in Delta effector tilt and mesh bed leveling:

@gperman said in Delta effector tilt and mesh bed leveling:

tilts back and forth when approaching the towers and traveling away from the towers

Deltas are EXTREMELY sensitive to this; it really must be fixed before going further.

If the tilt is totally consistent, it indicates a geometry problem. Most common is that the spacing "between" the two arms at a given single carriage does not match the spacing of those same too arms at the effector. One classic cause for this is placing a spring between the arms to pre-load play out of the rod ends. Absolutely do not do that.

There are some other possible geometry problems. Can you post a few pictures of the printer itself, taken from different distances and angles?

If the tilt is either inconsistent, and/or specifically varies depending on effector motion TO vs FROM the tower, that is an indicator of play. You just have to find and correct that.

I can get some images tomorrow. The tilt is inconsistent.

I took the effector off today with the arms attached to the blocks that attach to the carriages, the joints were tight but not too tight.

They do have O-rings around each end to help keep preload."the spacing "between" the two arms at a given carriage does not match the spacing of those same two arms at the effector"

How do I measure to the center of a sphere? I've been measuring the outer OD of the rod, closest to the joint at the effector and at the carriage.

I am realizing mag rods are probably in the future, I can see no other way to have sustained preload without some sort of cinching device (rubber band, flat head screw cranked in to "swage" out the inner spherical joint, etc.)

-

@clearlynotstef said in Delta effector tilt and mesh bed leveling:

What probe are you using. Everything needs to be square, the holes on the carriages need to be exactly as far apart as they are on the effector. The left hole needs to be the exact height as the right hole on both the carriage and the effector (ie the carriage isn't rotated) there's a lot of things that cause tilt

I am using the probe that came with my Anycubic Predator. A digital microswitch positioned 16.85mm below the nozzle.

-

@gperman you take the sphere off and carefully measure the distance between the holes on the carriage and effector

-