PT100 temp questionable

-

You can test the accuracy of the PT100 interface by connecting fixed resistors in place of the PT100. Search the web for "PT100 table" to find how resistance relates to temperature. For example, a 180 ohm resistor should give a reading just over 211C.

-

Yeah laser thermometer show 180c when at 290 DWC and has to be that Hi to print PLA

I’ll check with a resistor but then why would the PT1000 be showing the same error as it connects to the board and the pt100 to the daughter board?

WeirdUnless connection at the effector is iffy

-

@Carlo said in PT100 temp questionable:

Yeah laser thermometer show 180c when at 290 DWC and has to be that Hi to print PLA

If you mean an IR thermometer, those are useless for measuring the temperature of a small area such as a nozzle, or even a heater block.

-

Thanks... so would 100 equal 0 ?

-

@Carlo

Cheers DC

put 100 in shows 3.9c

put 220 in shows 324.5c bang on ish.0011100 something.

I'm just thrown by printing that very roll of PLA at 195c on my other printer and this one previously always at 210c and it would ooze at that now having to up it to 290c and ideally it needs to be a little hotter even -

@dc42 it was the heater block but didn't expect over 100c error tbf using the ir

-

Hi,

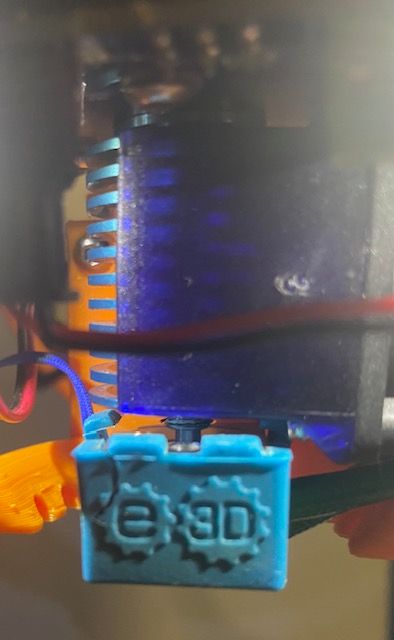

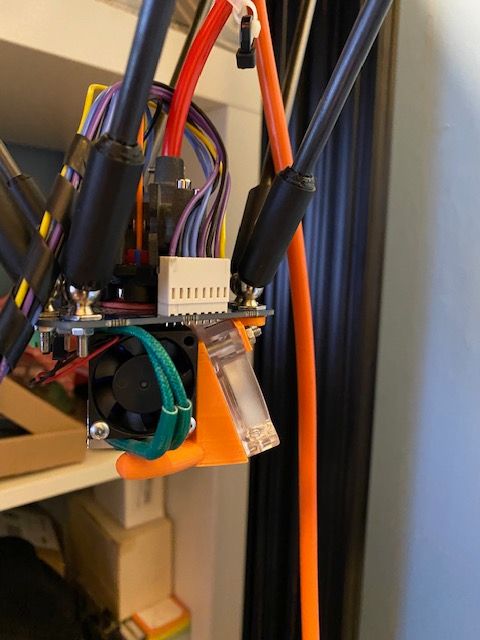

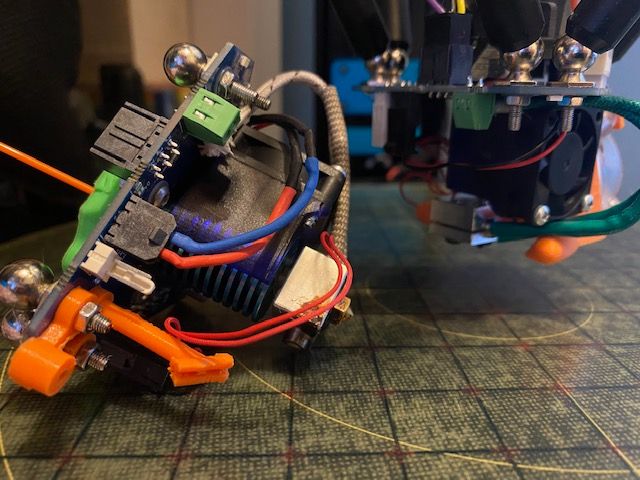

Is it possible the temps are being displayed wrong as I have fitted 3 Pt100 cartridges from e3d plus a new daughter board and pt1000 and 104 thermistor all with 22awg silicone wire which I cant print pla with the e3d 104 as I cant raise the temps above 285c and the pla is not molten I've re crimped the cabling used the cabling that came from e3d swapped pt100 boards but always the same results

At ambient the hotend steadily rises in temp while the bed doesn't and that's all the sensor types board combo's

Also (not important) there is a spelling mistake in the following:

Error: M303: heater 1 target temperature must be no hiher than the temperature limit for this heater (285.0C)I'm just seem to be going round in circles?

What can I test check next?Cheers

C -

On your hot end, is there definitely a gap of several mm between the top of the heater block and the bottom of the heatsink?

-

Hi DC it is definitely setup properly

all freshly redone new heater, sensor and crimps, daughter board new fans all E3D

all freshly redone new heater, sensor and crimps, daughter board new fans all E3D

and multiple of even replaced the bed with printbite+ and unless I crank it above 290 won't stick the perg line lifts when it move to print because its not hot enough I've redone my config every-time I swap the sensor tried titanium heat breaks coated copper heater block and standard break and block.

and currently the pla I need to crank heat up for is at 200c printing a zesty v2 adapter on my ender 3 3 feet away so it's not filament ...no doubt its me doing or not doing but I'm clearly not smart enough to figure it out. -

Does the PT100 read correctly at room temperature?

-

@dc42

Max difference is 4c higher with PT100 but it creeps up I just put the resistor (just found it in the bubble wrap bag) that came with the board shows -0.9c to -1.1c

with e3d thermistor its more like 0.9c higher and it creeps up -

So I left it a few hours all powered off switched on and bed shows 27.2/3c hotend showed 32.5/6c now dropped to 30.2c

my ender bed and hotend are at 27.3/6c so not sure it is correct at room temp.Cheers

C -

So you possibly have an error of around 3C at room temperature. I presume that's due to you using a 2-wire connection and having some resistance in the wiring or the connections.

It's possible that the resistance of the connections is increasing at higher temperatures and causing a greater error, but I think it's unlikely. The fact that you have tried a PT1000, thermistor and PT100 and all have the same problem suggests that the temperature at the sensor really is that high.

The PT100+daughter board uses the ADC built into the MAX31865 chip, whereas the PT1000 and thermistor use the ADC in the Duet main processor. The conversion from sensor reading to temperature is done by different parts of the firmware too. So there is no hardware or firmware fault I can think of that would similar degrees of over-reading with different sensors.

Maybe it's a cooling issue, i.e. too much cooling air blowing over the nozzle? With the print cooling fan turned off, what temperature do you need to extrude and print?

-

Hi DC,

I'm not running part cooling but if I put part cooling on directed at the sensor having taken it out of the block or in the block temp doesn't change well doesn't go down?

I've run 4 wires now no change.

I thought maybe interference from the other cabling so I ran wires outside the frame and over the top made no difference when its extruding @280c you can tell its not molten with no fan on its should be rubbery for a few seconds when I print the purge line you can tell it's not hot enough it doesn't leave that flat blob as it move to start the print it lifts it back up its not hot enough to stick so I guess I can put the 2 Ethernet back in.

Just off topic was the DWC freezing after righting to console fixed in 3.1.1 when connected to Pi or still to be fixed ?Cheers

C -

@Carlo said in PT100 temp questionable:

I've run 4 wires now no change.

I would expect using 4 wires to have reduced the approx. 3C over reading you were getting at room temperature.

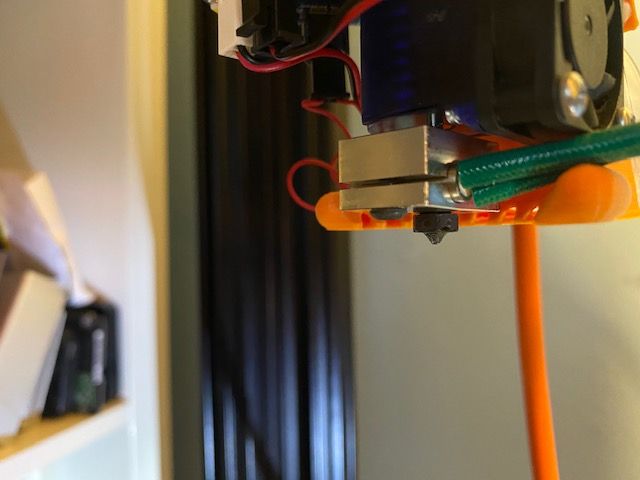

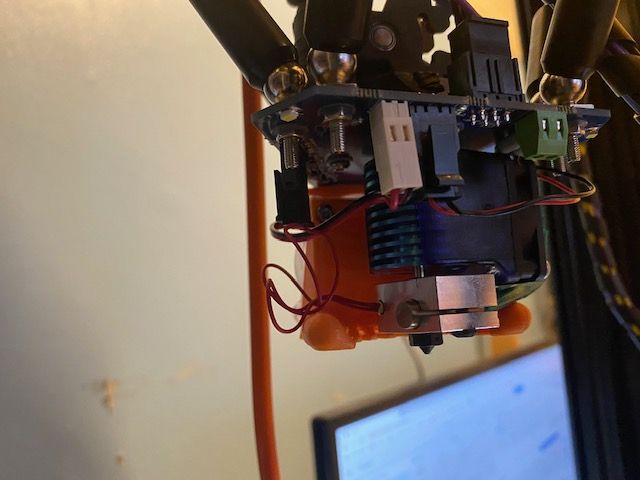

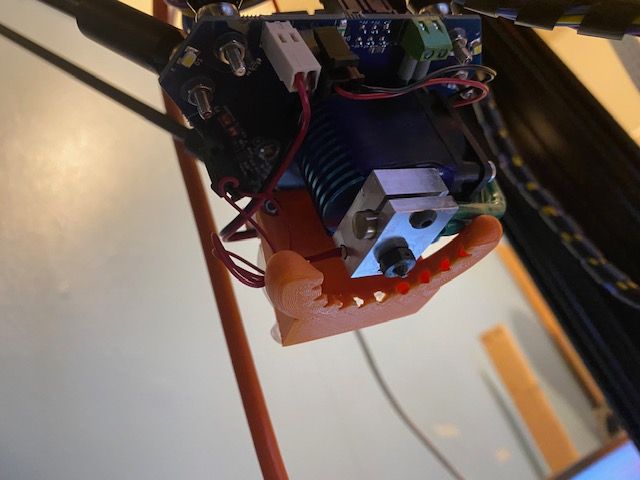

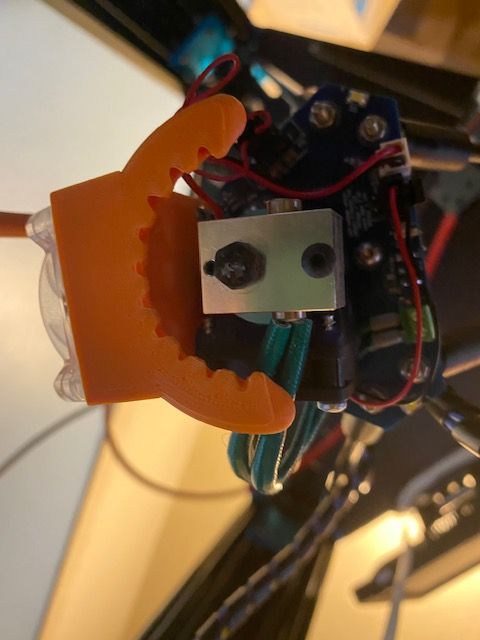

Please can you temporarily remove the silicone sock from the heater block and paste a few more photos of the hot end taken from different angles.

-

-

Thanks. I can't see anything wrong.

What size is the nozzle supposed to be, and are you certain that it really is that size? Have you tried replacing it?

-

Hi DC,

That one is a Nozzle X E3D 0.4 it has 3 dots and yeah I have a E3D 0.4 brass see below.

Cheers

C -

So you have two effectors/hot ends. Do you have the same issue of needing a very high temperature to melt PLA with both of them?

Have you tried heating the hot end to e.g. 220C with the Bowden tube disconnected and then trying to push the filament through by hand? In case the real problem is a weak extruder drive.

PS - if you have a multimeter with a fine thermocouple attachment, you can feed the thermocouple into the heat break and down into the nozzle to get an independent reading of the temperature.

-

Yeah so just done that now I'm almost snapping the filament @220c but it does go through.

after changing the wiring I haven't tried a print so I'll try one now see how it goes maybe the temps are better at normal print temps now.Cheers

C