PT100 temp questionable

-

Hi DC it is definitely setup properly

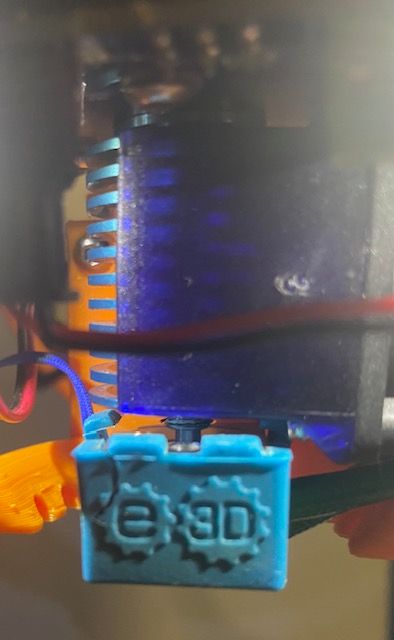

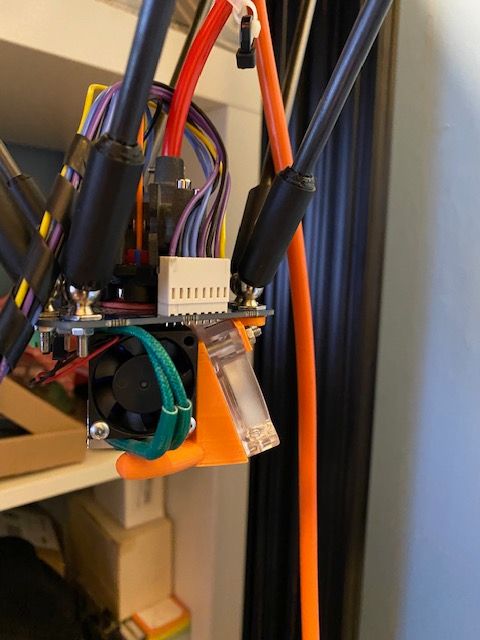

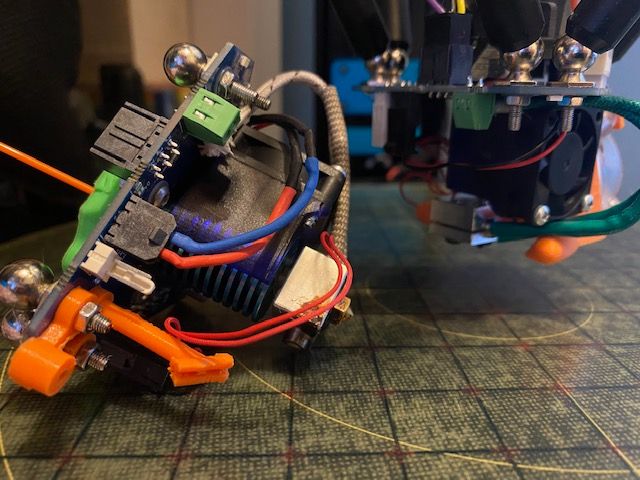

all freshly redone new heater, sensor and crimps, daughter board new fans all E3D

all freshly redone new heater, sensor and crimps, daughter board new fans all E3D

and multiple of even replaced the bed with printbite+ and unless I crank it above 290 won't stick the perg line lifts when it move to print because its not hot enough I've redone my config every-time I swap the sensor tried titanium heat breaks coated copper heater block and standard break and block.

and currently the pla I need to crank heat up for is at 200c printing a zesty v2 adapter on my ender 3 3 feet away so it's not filament ...no doubt its me doing or not doing but I'm clearly not smart enough to figure it out. -

Does the PT100 read correctly at room temperature?

-

@dc42

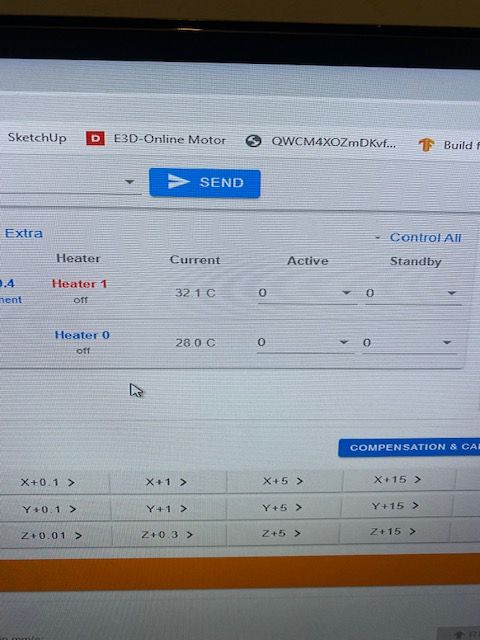

Max difference is 4c higher with PT100 but it creeps up I just put the resistor (just found it in the bubble wrap bag) that came with the board shows -0.9c to -1.1c

with e3d thermistor its more like 0.9c higher and it creeps up -

So I left it a few hours all powered off switched on and bed shows 27.2/3c hotend showed 32.5/6c now dropped to 30.2c

my ender bed and hotend are at 27.3/6c so not sure it is correct at room temp.Cheers

C -

So you possibly have an error of around 3C at room temperature. I presume that's due to you using a 2-wire connection and having some resistance in the wiring or the connections.

It's possible that the resistance of the connections is increasing at higher temperatures and causing a greater error, but I think it's unlikely. The fact that you have tried a PT1000, thermistor and PT100 and all have the same problem suggests that the temperature at the sensor really is that high.

The PT100+daughter board uses the ADC built into the MAX31865 chip, whereas the PT1000 and thermistor use the ADC in the Duet main processor. The conversion from sensor reading to temperature is done by different parts of the firmware too. So there is no hardware or firmware fault I can think of that would similar degrees of over-reading with different sensors.

Maybe it's a cooling issue, i.e. too much cooling air blowing over the nozzle? With the print cooling fan turned off, what temperature do you need to extrude and print?

-

Hi DC,

I'm not running part cooling but if I put part cooling on directed at the sensor having taken it out of the block or in the block temp doesn't change well doesn't go down?

I've run 4 wires now no change.

I thought maybe interference from the other cabling so I ran wires outside the frame and over the top made no difference when its extruding @280c you can tell its not molten with no fan on its should be rubbery for a few seconds when I print the purge line you can tell it's not hot enough it doesn't leave that flat blob as it move to start the print it lifts it back up its not hot enough to stick so I guess I can put the 2 Ethernet back in.

Just off topic was the DWC freezing after righting to console fixed in 3.1.1 when connected to Pi or still to be fixed ?Cheers

C -

@Carlo said in PT100 temp questionable:

I've run 4 wires now no change.

I would expect using 4 wires to have reduced the approx. 3C over reading you were getting at room temperature.

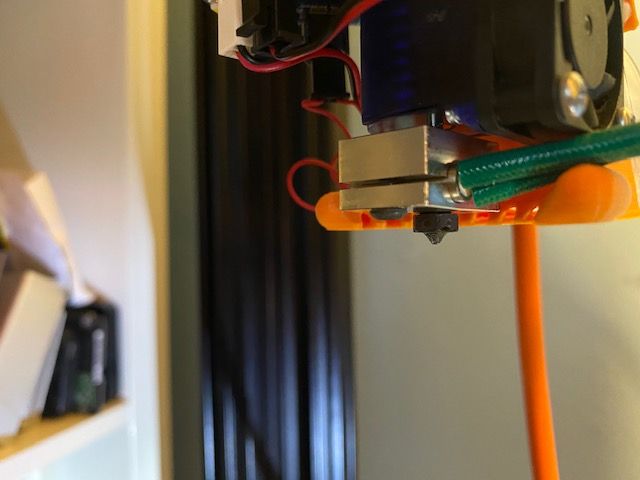

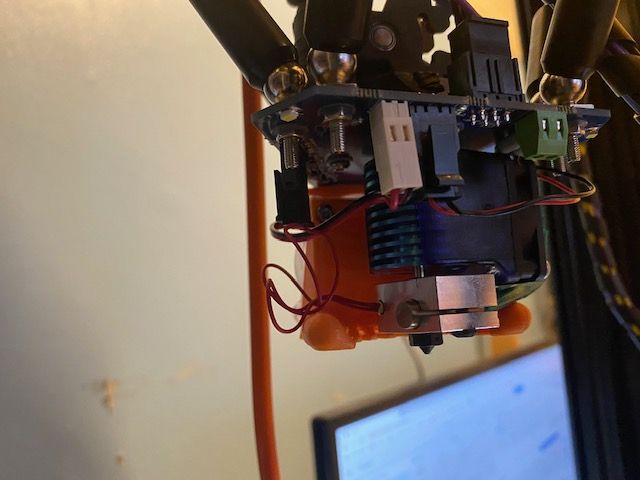

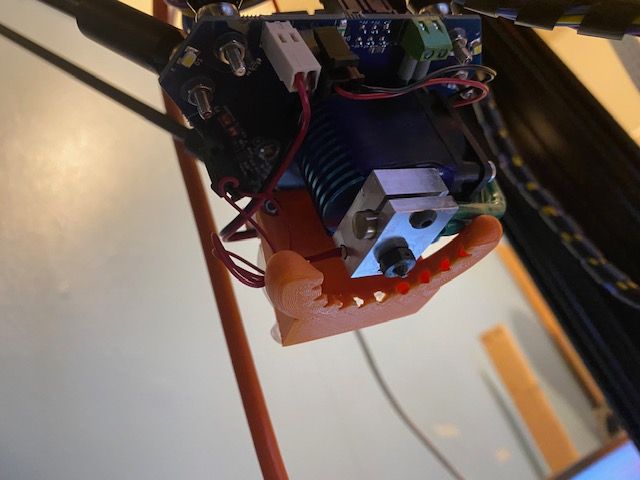

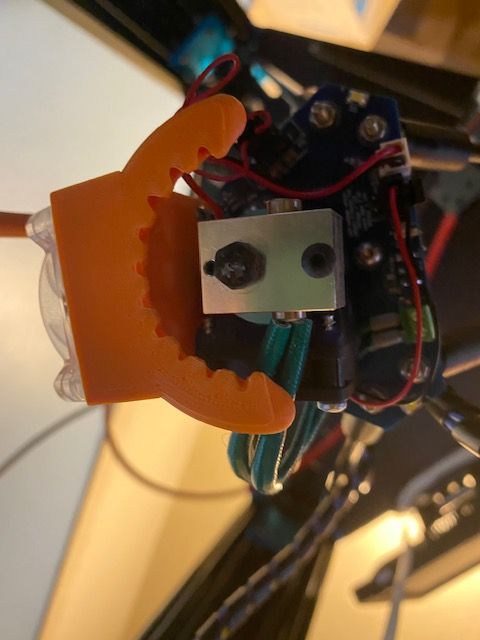

Please can you temporarily remove the silicone sock from the heater block and paste a few more photos of the hot end taken from different angles.

-

-

Thanks. I can't see anything wrong.

What size is the nozzle supposed to be, and are you certain that it really is that size? Have you tried replacing it?

-

Hi DC,

That one is a Nozzle X E3D 0.4 it has 3 dots and yeah I have a E3D 0.4 brass see below.

Cheers

C -

So you have two effectors/hot ends. Do you have the same issue of needing a very high temperature to melt PLA with both of them?

Have you tried heating the hot end to e.g. 220C with the Bowden tube disconnected and then trying to push the filament through by hand? In case the real problem is a weak extruder drive.

PS - if you have a multimeter with a fine thermocouple attachment, you can feed the thermocouple into the heat break and down into the nozzle to get an independent reading of the temperature.

-

Yeah so just done that now I'm almost snapping the filament @220c but it does go through.

after changing the wiring I haven't tried a print so I'll try one now see how it goes maybe the temps are better at normal print temps now.Cheers

C -

Do you have this problem with both hot ends? The theory I was formulating was that you have a partial nozzle blockage, needing a high temperature to overcome it.

-

Hi DC,

Yeah no difference between the 2.... having a bit of another issue where my machine is bouncing the carriages of the Endstops even though they are triggering ? And keep getting changing tool and can’t do anything until that goes to idle unless I hit Estop though nothing has changed in my config from earlier so I’ll give it go over tomorrow morning and try a print at normal temps out of interest I know you have used the printbite what bed temp have you used for PLA lower than usual?

-

I run the bed heater at 70C for PLA, however I know there is a drop of about 10C across the 4mm glass + PrintBite, so that actual bed surface temperature is more like 60C.

-

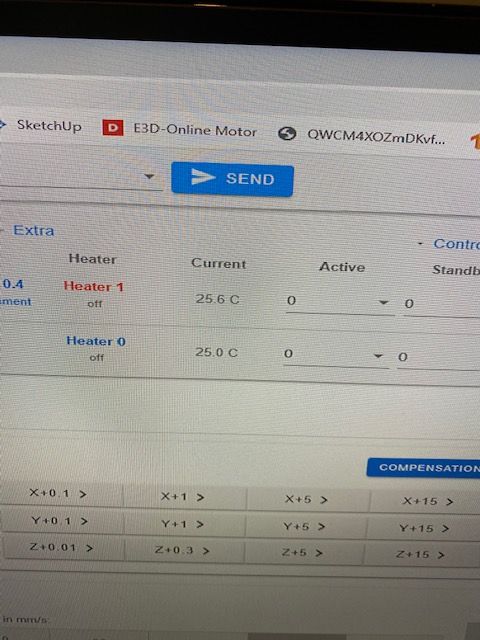

So after a few odd things going on last night couldn't find anything obvious in the wiring...but the temp for the hotend is now exactly the same as the ender 3 hot end and bed which is 0.5/6c of this bed ? now I never touched the daughter board just the endstop plugs to see if there was a loose connection which there doesn't appear to be though I was tugging on the board so not sure whats going on ...not that I did previously..possible there is a poor solder joint ? cant see anything obvious.

Yesterday evening

This morning

I'll just see if that changes over time

Thanks for your help much appreciated.

C -

Printing @210c though hot end temp doesn't seem very stable which is gonna be reflected in the quality but a step forward.

-

@Carlo said in PT100 temp questionable:

Printing @210c though hot end temp doesn't seem very stable which is gonna be reflected in the quality but a step forward.

Have you run heater tuning?

-

Yes and its in my config,M307 H1 A221.0 C100.7 D2.0 S1.00 V24.0 B0 ; disable bang-bang mode

The hot end temp is more stable when the part cooling fan is on little over 1c change fan not on 7/8c just straight up and down 205 ish to 212 ish @210 but the part has printed and not terrible my retraction is bang on:) but it is warped and I could see that happening as it printed the initial layers.

Hot end 210 bed 70 bed temp .1c shift temp chart straight line hot end a bumpy line smoother towards the end when the fan was on more and higher speed. -

Sometimes it helps to tune the D parameter by hand. If you get regular oscillations, increase D. If the temperature recovers slowly in response to changing loads (e.g. the fan turning on), reduce D.