Sending negative G91 values always sets axis to minimum position

-

I think you may be affected by some of the limitations of M584 in reprapfirmware 2, so please read the linked documentation to see what applies to you. Upgrading to RRF3 will remove some of those limitations. Even if you don't update to 3.1.1 which would require an updated config, you should at least update to 2.05.1 as 2.02 is quite old at this point.

-

@fcwilt said in Sending negative G91 values always sets axis to minimum position:

Move one of the axis, say X, into the middle of its range.

Then execute a G91 command and then a G1 H1 X-99 F100 commandThe problem when I do this is that the motor wont even spin, as it automatically sets itself to the lower limit of the axis... I am completely lost.

@Phaedrux said in Sending negative G91 values always sets axis to minimum position:

Even if you don't update to 3.1.1 which would require an updated config, you should at least update to 2.05.1 as 2.02 is quite old at this point.

I should try to do 2.05, I am worried of all the config changes I need to do if I decide to go with V3!

-

@jcsb1994 said in Sending negative G91 values always sets axis to minimum position:

The problem when I do this is that the motor wont even spin, as it automatically sets itself to the lower limit of the axis... I am completely lost.

Then first depress the end stop switch and try to do the move.

As I said if the end stop is already active at the start of the move then all that will happen is setting the position to the min value for that axis, assuming you have specified that the end stop is at the min end.

If the move does not happen with the end stop switch depressed then check the configuration of the end stop to insure that it is correct.

Frederick

-

Post your full config.g and what you're trying to accomplish.

-

@Phaedrux said in Sending negative G91 values always sets axis to minimum position:

Post your full config.g and what you're trying to accomplish.

I decided to update to firmware 3.1.1

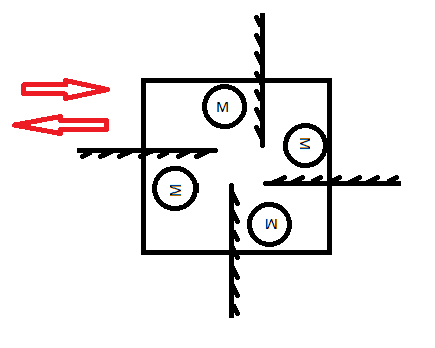

So I am slowly figuring out what needs changing in my config. My application requires 4 motors (A B U V) that are each operating a rack and pinion, disposed in a square. Imagine each motor's rack is actually pushing on a different side of an imaginary square to expand and retract each of its side. Its for simulation purposes.

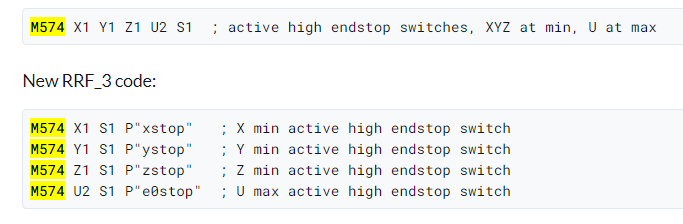

I didn't manage to make the endstops work yet. I am puzzled because it seems like RR2 supported the way I used M574

my config.g so far:

; Drives M584 A0 B1 U2 V3 ; map drives for first band M564 H0 ; can move motors without homing M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes backwards M569 P3 S1 ; Drive 3 goes forwards M350 X8 Y8 Z8 E8 I1 ; Configure microstepping with interpolation M92 X50.929 Y50.929 Z50.929 E50.929 ; Set steps per mm M566 X100.00 Y100.00 Z12.00 E120.00 ; Set maximum instantaneous speed changes (mm/min) M203 X10000.00 Y10000.00 Z10000.00 E10000.00 ; Set maximum speeds (mm/min) Z wobbles at 800 M201 X1100.00 Y1100.00 Z1100.00 E1100.00 ; Set accelerations (mm/s^2); testing was done at 4500 4500 10 250 M906 X700.00 Y500.00 Z500.00 E500.00:500.00 ; Set motor currents (mA) M84 S0 ; Disable motor idle current reduction ; Axis Limits M208 A0:63 B0:63 U0:63 V0:63 W0:63 X0:63 Y0:63 Z0:63 E0:63 ; Set axis min-maxima G92 A0 B0 U0 V0 ; set all position to 0 along axis ; Endstops ;M574 A1 B1 U1 V1 W1 X1 Y1 Z1 E1:1:1:1 S0 ; Set active low for all 8 motors M574 A1 S0 P"xstop" ; active low endstop switch M574 B1 S0 P"ystop" ; active low endstop switch M574 U1 S0 P"zstop" ; active low endstop switch M574 V1 S0 P"e0stop" ; active low endstop switch -

Hi,

One thing you need to do is verify that your end stop switches are working.

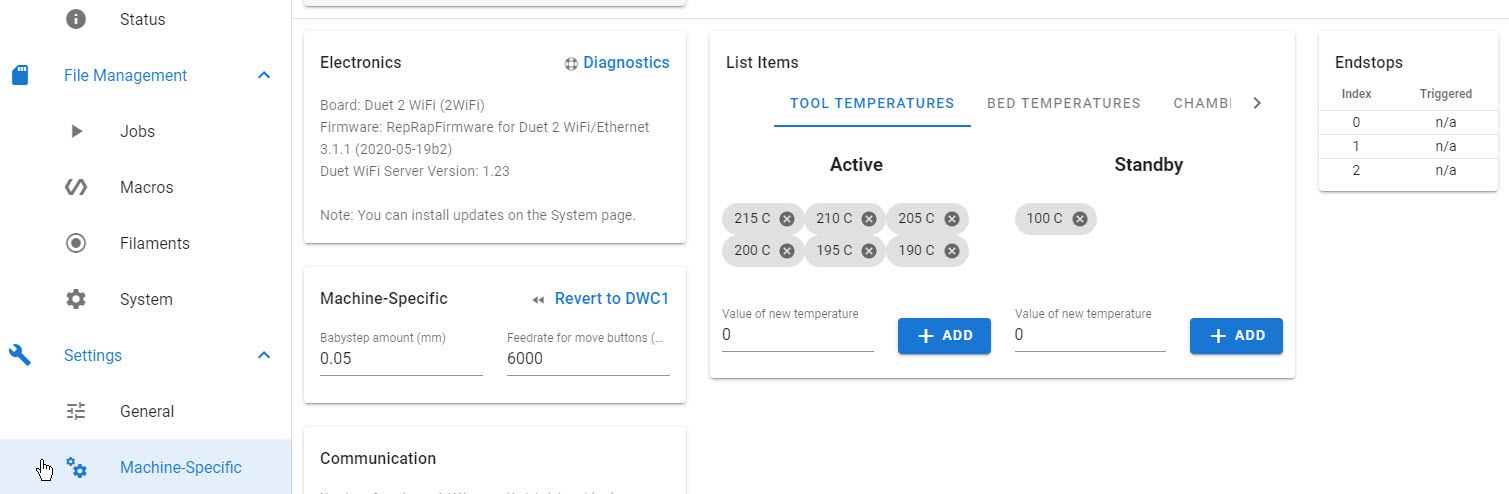

Since you have upgraded to 3.1.1 you can check in Duet Web Control (DWC).

On the left side select "Machine-Specific" and then over on the right you can see the status of the end stops.

The problem you are having is related to the end stops and you need to get them working correctly.

Frederick

-

@fcwilt said in Sending negative G91 values always sets axis to minimum position:

On the left side select "Machine-Specific" and then over on the right you can see the status of the end stops.

Wow, thanks for this info.

Here is the code I have for my endstops

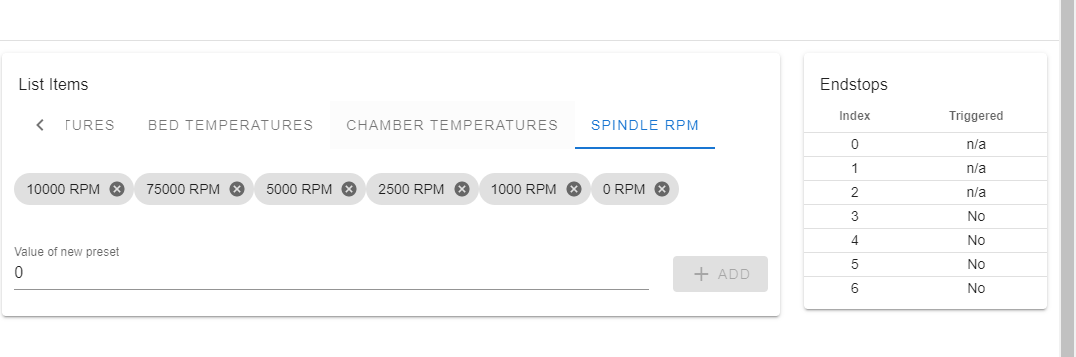

M574 A1 S1 P"!xstop" ; A min active LOW endstop switch M574 B1 S1 P"!ystop" ; B min active LOW endstop switch M574 U1 S1 P"!zstop" ; U min active LOW endstop switch M574 V1 S1 P"!e0stop" ; V max active LOW endstop switchAnd here you can see that it activates 4 endstops (in no state, but turn to yes when I press them)

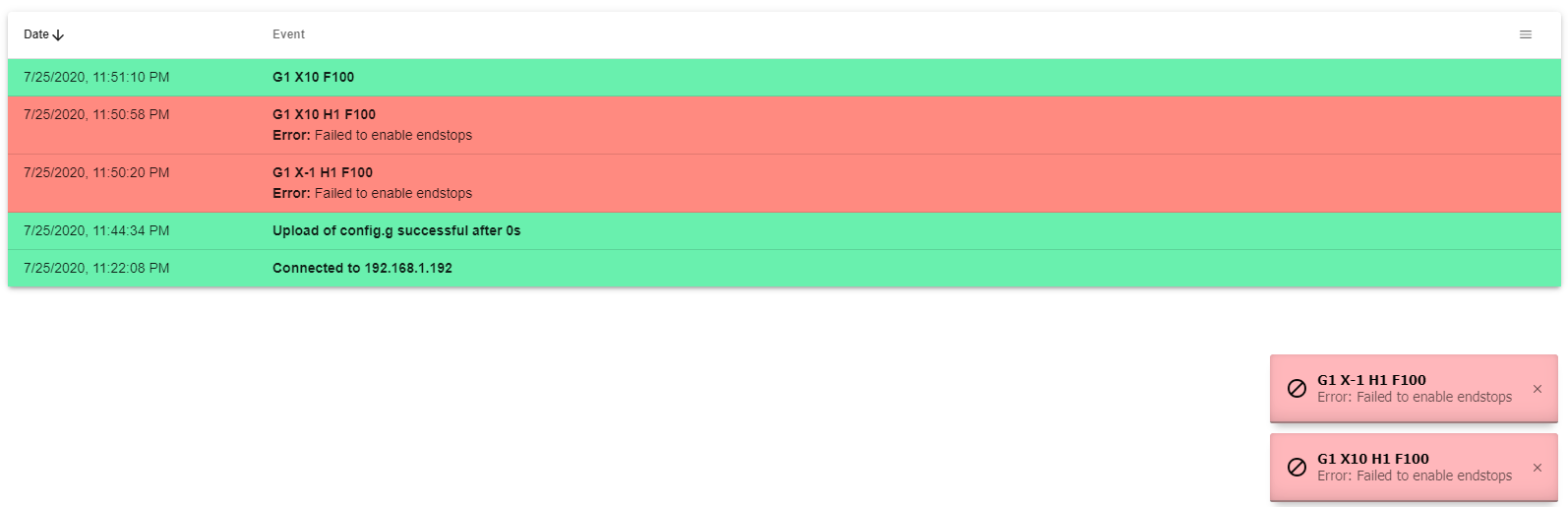

Small question: ow do I determine which endstop is which index? for example, my E0 endstop is index 4, Z is 5, x is 3 and y is 6 (seems randomly assigned).Now, it would seem like the endstops are active since I can press them and they turn to yes. But there is a weird error when I try to move my motors with H1:

I cannot find this error code online?

-

@fcwilt said in Sending negative G91 values always sets axis to minimum position:

One thing you need to do is verify that your end stop switches are working.

Hmm...

I was looking at the config.g you posted.

It is a strange mix of X,Y,Z and A,B,U,V.

I see M584 with A,B,U,V

I see M350 with X,Y,Z,E

I see M92 with X,Y,Z,E

I see M574 with A using X endstop, B using Y endstop, U using Z endstop, V using E0 endstop.How many stepper motors does this device have?

Frederick

-

Yes you definitely need to clean up your config.g a bit.

Condense your commands and ensure they contain all of the axis you plan to use. Make sure the commands are in the correct order. Namely that M584 that creates the axis must come before the commands that set a parameter for those axis.

I understand your post about the 4 axis to move a plate like a rack and pinion, but are there other axis involved in motion?

-

@Phaedrux said in Sending negative G91 values always sets axis to minimum position:

I understand your post about the 4 axis to move a plate like a rack and pinion, but are there other axis involved in motion?

At a certain point, we will copy the structure, so we will have 8 axis (basically 2 squares like I have shown you). But for now, I want to have the first half functioning properly with the endstops (they are located on the inside, when the 4 racks are fully retracted). Since I do not have the extension board yet, nor the motors, I am not adding the additional axis yet in my config.

-

Then you need to create the config file using just X,Y,Z,E or A,B,U,V but not a mixture of both.

Frederick

-

I finally managed to make it work. I switched my 4 axes to X, Y, Z and U. I do not know why but trying A B U V didn't work no matter what I did. It might be because I still had my XYZ axis setup, so I really had 7 axes, and maybe the endstops were just checking the first axis they were setup for (i.e. X instead of A, Y instead of B, and Z instead of U)