What are the G Code commands that affect stepper feedrate?

-

Hi,

I am trying to send commands that last for a specific period of time, given their feedrate and amount o move, this should be more or less predictable.This command:

G1 H1 X-25.000000 Y-25.000000 Z-25.000000 U-25.000000 F1500.000000is supposed to move my motors for about 1 second, but it takes around 1.7s, although the distance of 25mm is respected.

I have setup my config to convert steps into axis movement correctly since distances are right. But I do not know what can be wrong to have 70% time increase on my expected feedrate!

here are the commands I think could have an impact:

M92 X50.929 Y50.929 Z50.929 U50.929 E50.929 ; Set steps per mm M566 X100.00 Y100.00 Z100.00 U100.00 E120.00 ; Set maximum instantaneous speed changes (mm/min) M203 X10000.00 Y10000.00 Z10000.00 U10000 E10000.00 ; Set maximum speeds (mm/min) M201 X1100.00 Y1100.00 Z1100.00 E1100.00 ; Set accelerations (mm/s^2); M906 X700.00 Y700.00 Z700.00 U700.00 E500.00 ; Set motor currents (mA) M84 S0 ; Disable motor idle current reductionThanks for your help...

-

Are you taking acceleration and deceleration into account?

-

@Phaedrux Yeah! (not in this example however). But even when correcting Feedrate for accel/decel losses (which are pretty small) I have more than 60% increase in time taken (feedrate is basically 2/3 of what is should be on paper)

-

There was a question similar to this recently that DC42 had replied to that may explain what's actually going on but I can't seem to find it right now.

If you looked back through his posts you may find it.

-

@Phaedrux I tried looking at his recent posts, but there are so many!! I didnt have any luck finding something on feedrate bad conversion.

My program used to work however. I wonder if this can be caused by upgrading to reprap version 3 (I used to be on RRF2 when it worked).

-

@jcsb1994 said in What are the G Code commands that affect stepper feedrate?:

My program used to work however.

What was the program? Maybe give some more context on what you are trying to do, how it worked before, and what it does now.

-

@Phaedrux I just found out what made the feedrate slow down. It isnt the firmware update, it is the fact that I added motors to my board! It seems like operating 4 motors compared to only 1 drains too much current for the duet3d wifi. Is there a solution to this. As of now (I just tested) with this command:

while true G1 U25 F1500 G1 H1 U-25 F1500 M0 H1I get around 1 sec per move (plus wastes from accel/decel)

But when I use this command:

while true G1 X25 Y25 Z25 U25 F1500 G1 H1 X-25 Y-25 Z-25 U-25 F1500 M0 H1Then I get up to 1.7s per move, as I explained before. It seems linear however, I get a little slower at 2 and 3 motors (around 1.5s per move).

Is there a current setting to correct this or it is a physical limit to the Duet3D wifi? I am using

M906 X700.00 Y700.00 Z700.00 U700.00 E500.00 ; Set motor currents (mA)for my motor currents, and I my 4 motors are actually

-

2 X - 17hd48002h‑22b

-

2 X - 17hm15-0904s

all of which are nema17. Is there a setting for max board current? I am worried about increasing the max current for my individual motors, the 17hm15 can't/shouldnt go a lot higher.

Am I right thinking it is a current issue?

Thanks! -

-

@jcsb1994 said in What are the G Code commands that affect stepper feedrate?:

! It seems like operating 4 motors compared to only 1 drains too much current for the duet3d wifi

i think i would look at the voltage drop in you supply and wiring before putting the blame on the board

https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors

(unless the board is a clone, in which case it likely has 35um copper instead of 70um)

edit: playing with highlighting feature of the wiki

-

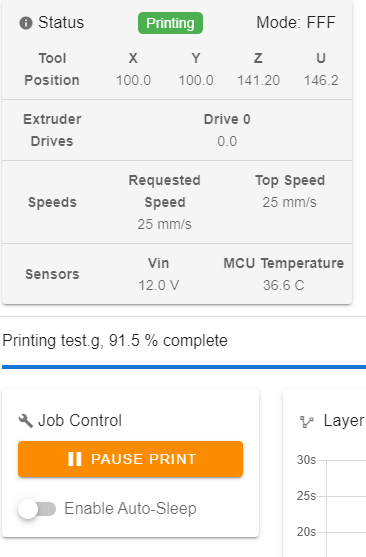

@bearer no voltage drop! During movement:

It is not a clone, so I am really puzzled right now...

-

running unto back emf issues them maybe, 12v might not be enough to reach the desired speed? its certainly not a current issue.

https://www.reprapfirmware.org/ and emf calculator, there is also a section in the wiki linked above

-

After commanding those movements send M122 and report the results.

-

@Phaedrux

I tried increasing the Vin to around 24V but the movements are still slowed. my 24V power supply was pushed to its current limits however (4.8A consumption, and its rated 5A).Here is what I get with M122. Everything looks fine even at 23.5V but the problem persists.

=== Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.1.1 running on Duet WiFi 1.02 or later Board ID: 08DGM-917NK-F23T0-6J9DL-3SS6K-KW9SH Used output buffers: 2 of 24 (22 max) === RTOS === Static ram: 27980 Dynamic ram: 92936 of which 20 recycled Exception stack ram used: 472 Never used ram: 9664 Tasks: NETWORK(ready,488) HEAT(blocked,1456) MAIN(running,1824) IDLE(ready,80) Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:00:54 ago, cause: power up Last software reset at 2020-07-28 12:22, reason: User, spinning module GCodes, available RAM 9872 bytes (slot 2) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task MAIN Error status: 0 MCU temperature: min 34.2, current 34.6, max 34.7 Supply voltage: min 23.5, current 23.5, max 23.6, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: ok, SG min/max not available Driver 1: ok, SG min/max not available Driver 2: ok, SG min/max not available Driver 3: ok, SG min/max not available Driver 4: standstill, SG min/max not available Date/time: 2020-07-28 16:13:24 Cache data hit count 94461989 Slowest loop: 9.87ms; fastest: 0.12ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 9 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 0.6ms, write time 0.0ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 169, MinFreeDm: 165, MaxWait: 16ms Bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves: 10, completed moves: 10, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === Heat === Bed heaters = -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is ready with "M122" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. -

@jcsb1994 said in What are the G Code commands that affect stepper feedrate?:

all of which are nema17. Is there a setting for max board current? I am worried about increasing the max current for my individual motors, the 17hm15 can't/shouldnt go a lot higher.

So you have two different motor types trying to do a coordinated move together?

They seem to be quite different motor specs. One rated at 900ma and the other at 1700ma. Setting the current to 700ma for the first would be fine but may be too low for the second.

-

@Phaedrux Ok, so I changed my max current values for 1400mA on the 2 bigger motors. But it didn't change anything.

I also had a weird message.

I started by uploading this script with the upload and start button

echo 12345 while true G1 X25 Y25 Z25 U25 F1500 G1 H1 X-25 Y-25 Z-25 U-25 F1500 M122 M0 H1

And made sure the movements were taking significantly more time than a second each.

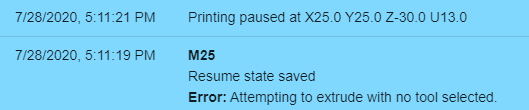

Then I pressed on pause, and this message appeared:

The Printing paused message seems wrong. there isn't even a line ith these values! is the code being changed when uploaded to the Duet3d??

-

you pressed pause and the duet ran pause.g which by default contain some retraction g-code...

-

@bearer Ha ok thanks I understand.. I didn't see it this way I thought it meant where it paused on the running program.

And if a motor current is limited in such a way that it limits its max speed below the required feedrate, will the other motors slow down even if their current max setup will let them reach the required feedrate?

-

Well there's no way for the firmware to know if back emf or whatever is preventing a motor from behaving as commanded because it's an open loop system, so no, the motion planner shouldn't be slowing down movement because of that.

The reason for asking for the M122 report was to see if there were a number of hiccups being counted, which would be an indication that the internal step rate was being exceeded, which could cause slow down and micro pauses as it tries to keep up. That doesn't look like the case here though.

I'm afraid we'll have to wait until DC42 returns from vacation to be able to really explain what might be going on.

-

we're also missing the microstepping setting and one motor is 0.9deg and the other 1.8deg?

-

@bearer I have tested with 3 motors of the same model (the one at 1.8deg step) and no luck, the moves still take 1.5s each instead of 1 (1.1 maybe with accel/decel). It doesnt seem like having different motor models change something.

here are my config settingsM350 X16 Y16 Z16 U16 E8 I1 ; Configure microstepping with interpolation M92 X101.858 Y50.929 Z101.858 U50.929 ; Set steps per mmAnd may be all my settings just in case

; Drives G91 M584 X0 Y1 Z2 U3 E4 ;M584 A0 B1 U2 V3 ; map drives for first band M564 H0 S0 ; can move motors without homing, S0 can ignore axis limits M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M350 X16 Y16 Z16 U16 E8 I1 ; Configure microstepping with interpolation M92 X101.858 Y50.929 Z101.858 U50.929 ; Set steps per mm M566 X100.00 Y100.00 Z100.00 U100.00 E120.00 ; Set maximum instantaneous speed changes (mm/min) M203 X20000.00 Y20000.00 Z20000.00 U20000.0 E20000.00 ; Set maximum speeds (mm/min) Z wobbles at 800 M201 X1100.00 Y1100.00 Z1100.00 E1100.00 ; Set accelerations (mm/s^2); testing was done at 4500 4500 10 250 M906 X700.00 Y1400.00 Z700.00 U1400.00 E500.00 ; Set motor currents (mA) M84 S0 ; Disable motor idle current reduction ; Axis Limits M208 A0:63 B0:63 U0:63 V0:63 W0:63 X0:63 Y0:63 Z0:63 E0:63 ; Set axis min-maxima G92 X0 Y0 Z0 U0 ; set all position to 0 along axis ; Endstops ;M574 A1 B1 U1 V1 W1 X1 Y1 Z1 E1:1:1:1 S0 ; Set active low for all 8 motors on Jack M574 X1 S1 P"!xstop" ; A min active LOW endstop switch M574 Y1 S1 P"!ystop" ; B min active LOW endstop switch M574 Z1 S1 P"!zstop" ; U min active LOW endstop switch M574 U1 S1 P"!e0stop" ; V max active LOW endstop switch -

So I guess there is no other known possible error source? Next step is further research and possible help from @dc42 ?