First Post & few Questions (Low+High Endstop & Blobs Issue)

-

Would it help if i mesure the resistance of the thermisto to gett an approximate value?

-

yes

measure the resistance at room temperature.

then measure the resistance at 100C

then measure the resistance at 200Cyou will need a thermometer or other tool to determine the temperature. do not measure the temperature using the same thermistor.

then plug in those 3 sets of values into the calculator (click on the beta value and select custom)

https://configtool.reprapfirmware.org/Heaters -

ok I'll do it tomorow because the printer is still working now an and still hot.

Roomtemperature 21 or 25 °C? -

@FITT

both work as the value can be calculated from both. -

ok. I see; i didn't click on the beta.

thanks alot @Veti and @deckingman

this helped a lot -

@FITT You should still print a temperature tower as I suggested earlier. Then use the lowest temperature which gives good results according to that tower, regardless of the displayed value.

-

Update:

I've mesured the resistance of the thermistor an succesfully put it into the config.g .

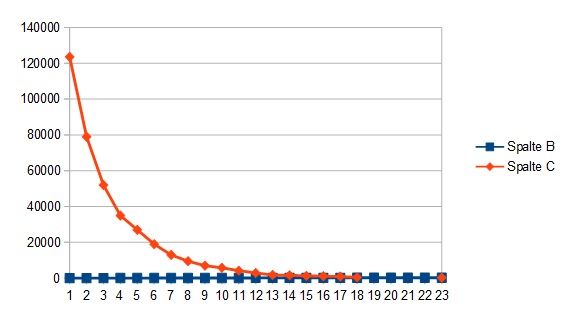

But I had some trubble. I had no thermometer, but I had another printer who still worked fin. so I put the thermistor into the hotend and configured the tempretures at this printer. Then I was able to mesure the resistance of the thermistor. I did it at 10 °c stepps. I putted the results into an excelsheet and could verify if it was a curve at the diagram i made out of the results.

Like that I got this result at the onlineconfigurator:

- T99074 B6026 C2.830042e-7

I put this into my config and run a few printtest just for fun.

Now I'm going to make the temperature tower that @deckingman suggested

Greatings

FITT

-

Update:

I did the temp towers. As you said, it is recomandet tu use the lowest temperature possible; in my case it was 190°C.I just have to set now the stalldetection and everything will be working.

Thanks for your help

FITT

-

@FITT

while that works for now, i would suggest to order some known thermistors anyway.

https://www.aliexpress.com/item/32816085854.html

and

https://www.aliexpress.com/item/32847452724.html -

Hello,

@Veti i'll get some new thermistor in a few days when i order a few more parts that i need. the heater is already new and 24 V.

I'll put a second linearguidance to the diamondcarriage.

I figured out that during the fast print, it moves to much (0.5mm). the printed corners are not straight.Yesterday I scripted a wipetower into prusa. My goal was to evitate oosing colors into the actual printed color while toolchanging. That worked also fine but wasted a lot of fillament. Luckily the printed part was perfect.

I worked with the setup that @deckingman mentioned in his blog (toolsetup: 0.9:0.025:0.025:0.025:0.025....) but the inactiv color oosed somtimes into the actual color.

Today i'm going to ad a servo which will whipe the nozzle and catch the filament which is purged. Like this i'm going to avoid this wipetower an ooze out the unused color at a specific height and befor a toolchange. and prepare the actual tool. -

@FITT said in First Post & few Questions (Low+High Endstop & Blobs Issue):

I figured out that during the fast print, it moves to much (0.5mm). the printed corners are not straight.

i was expecting that. that is why i mentioned the igus zero backlash setup.