Secondary Tool move breaks Z homing

-

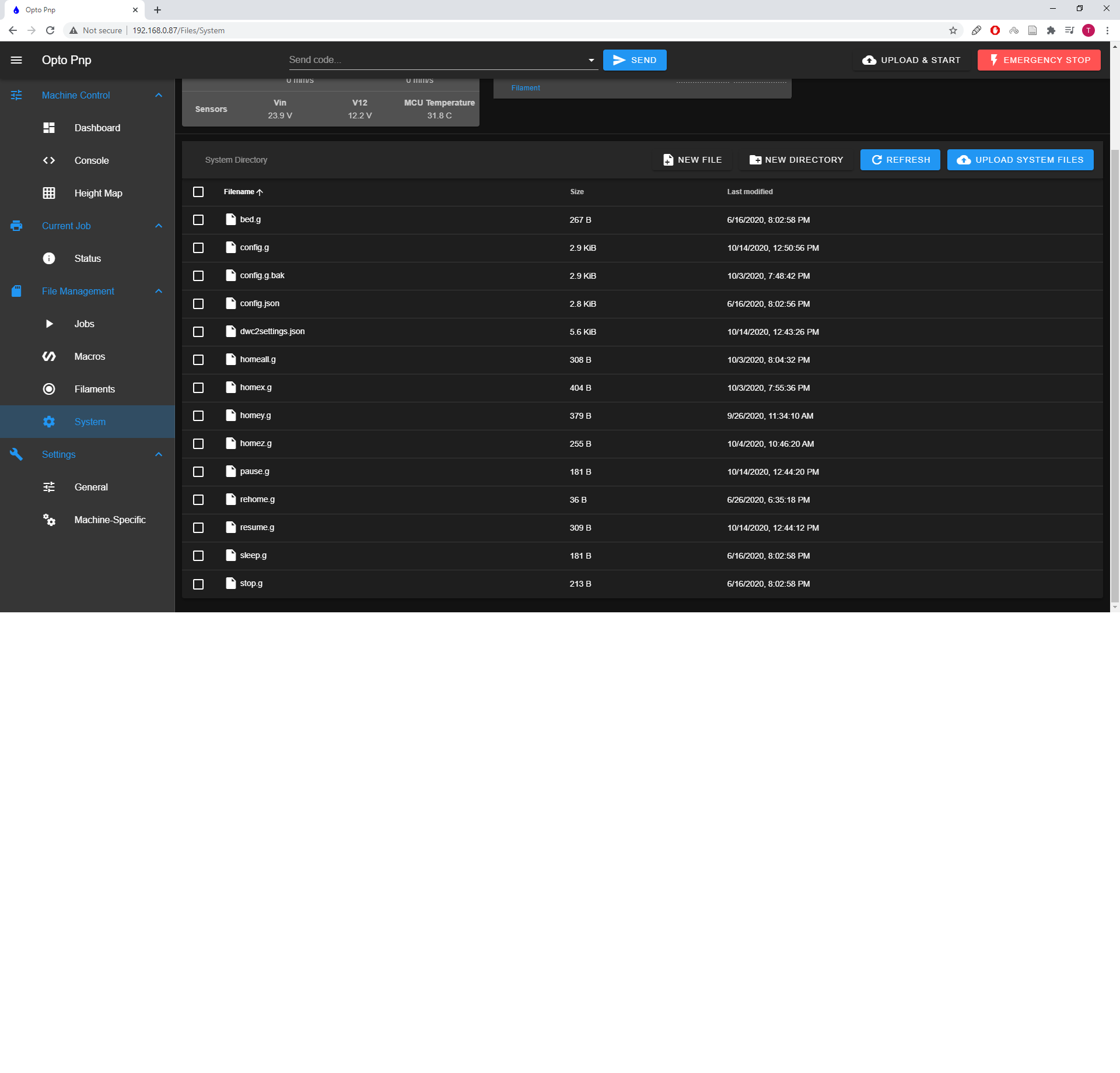

These are all of the homing scripts.

homeall.g homez.g homey.g homex.g

The maniche is Pick and Place software. The offsets are handled inside openpnp.

However this issue can be replicated without the openpnp. Just by gcode above.In the other thread i'm dealing with issue how to configure absolute independent rotation axis.

Honestly i do not know what causes the issue. I have spend a lot of time debuging this issue because is seemed to be a random, unitl i found out it stop happedning when i disabled the other pnp head. After that i was able to replicate it by the gcode above.

-

@optical said in Secondary Tool move breaks Z homing:

I do not have any tool change scripts inside my configuration.

What we are asking is whether you have files tfree0.g, tpre0.g and tpost0.g in /sys on the SD card, and similar files for tool 1; and if so, what is in them.

-

I do not have any tool change files tfree0.g, tpre0.g and tpost0.g in /sys on the SD card

-

Thank you.

@optical said in Secondary Tool move breaks Z homing:

G0 180 ; Tool 0 moves to 180

I presume that is a mis-print, because G0 180 doesn't make sense (there is no parameter letter before the 180). What should it be? Does the problem still occur with these three G0 commands removed, i.e. just the T commands between G28 and G28 Z?

-

PS:

@optical said in Secondary Tool move breaks Z homing:

M208 E-18000 S1 ; set axis maxima M208 E18000 S0 ; set axis maxima

Extruder are not axes, so those commands won't do anything; but I wouldn't expect them to mess anything up.

-

So i tested again the minimal sample and discovered following:

G28 T0 T1 G28 Z; Works fineG28 T0 G0 Z10 T1 G0 Z0 T0 G0 Z10 G28 Z ; works fineG28 T0 T1 G0 E10 G28 Z; failedThis makes me think that maybe the issue is related to the other thread regarding this machine.

Sorry for the previous gcode example. That has not been accurate enough. -

I have testing different driver mapping to ensure that the issue is not connected to board it self.

After that i confirmed that the Induction sensor(it has led on the back) is still working after the failed homing, to ensure that somehow the input has not been disabled.

-

Thanks. Please can you upgrade the firmware to 3.2beta1 and see if the issue is still present.

-

Hi.

I have tried 3.2beta2 and 3.2beta1 issue present in both of the versions. -

Thank you. I will try your config file on my bench setup and try to reproduce the problem.

-

Hi,

today i have been able to produce behavior to use the tools with axis mapping to remember their position.

I have changed the rotation to be represented by axis X(One nozzle). The other i have mapped to axis V to be able to use M563 to change driver mapping for Axis X.However, the issue with inverting axis is still present. This time right after homing.

G28 G28 ZNote: I think it would be nice to allow using M563 to remap any axis. Due to this limitation i had to move my X axis to be labeled as U. Which makes things rather messy.

G28 Z G28 V G28 Z ; FailesThis is the minimal usecase when the Z homing failes.

It is propable related to the way i'm homing the axis which does not have endstops and are infite(free-rotation).Could you help me maybe change the way i'm homing the rotation axis ? Is there Gcode which would just declare the axis as homed ?

Currently i set the stall detection to lowest value and move.

These axis can be homed in any position.The other possibility is that the Z axis breaks whenever the second tool/driver moves.

Configuration:

homeall.g config.g homez.g homey.g homex.g homev.g homeu.g -

@optical said in Secondary Tool move breaks Z homing:

Is there Gcode which would just declare the axis as homed ?

G92 will let you set the position of an axis.

https://duet3d.dozuki.com/Wiki/Gcode#Section_G92_Set_Position

-

I tested new homing scripts using G92 for the infinite axis. And i have come to conclusion that whenever the other drive(Currently V axis) moves. The Z axis homing becomes inverted.

-

After further testing it seems that somehow the input is inverted.

M574 Z2 P"!io0.in" S1Because the problem of the movement is "solved" not present when i remove the induction probe connector from the board.

Is it possible that switching from the probe endstop to sensorless endstop breaks the input ?After messing with the endstop settings. I think that really something is wrong with the input it self.

G28 T1 G1 X10 G28 Z ; Broken home M574 Z2 P"!io0.in" S1 G1 H1 Z+40 F500 ; stops immidiently even when sensor is not triggered M574 Z0 P"nil" G1 H1 Z+40 F500; Continues fine M574 Z2 P"!io0.in" S1 G1 H1 Z+40 F500 ; stops immidiently even when sensor is not triggeredI have tried to change io0 for io1. The issue is still present.

I have checked that the sensor is indeed working even when the problem with the io is present. -

Well the ! inverts the signal.

-

@Phaedrux Ofcourse it does the inversion is correct. The input works for the homing until the Tool 1 is moved then it stops working(propably gets inverted (uninverted)).

I'm suggesting that it is propably a bug inside the firmware. -

Post your gcode so we can see what's all going on.

-

-

Can you try add M400 before all of your instances of M913?

https://duet3d.dozuki.com/Wiki/Gcode#Section_M913_Set_motor_percentage_of_normal_current

Important! When M913 is executed, it does not wait for all motion to stop first (unlike M906). This is so that it can be used in the M911 power fail script. When using M913 elsewhere, you will typically want to use M400 immediately before M913.

; Axis Limits M208 U-7.7 Y-39.2 Z-22.5 S1 ; set axis minima M208 U650 Y400 Z22.5 S0 ; set axis maxima M208 X-18000 V-18000 S1 ; set axis maxima M208 X18000 V18000 S0 ; set axis maximaCan you try condensing that into just two commands?

-

@dc42 Did you managed to reproduce this issue ?