Toolboard Heater Tuning and Fan Error

-

it happens now every time i start a print

19.12.2020, 22:18:50 m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.2-beta4.1 running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-956BA-NA3TN-6J9DL-3S46S-99AUT Used output buffers: 1 of 40 (10 max) === RTOS === Static ram: 123292 Dynamic ram: 138756 of which 88 recycled Never used RAM 130056, free system stack 126 words Tasks: Linux(ready,83) HEAT(blocked,297) CanReceiv(blocked,831) CanSender(blocked,348) CanClock(blocked,352) TMC(blocked,20) MAIN(running,669) IDLE(ready,19) Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:36:36 ago, cause: software Last software reset at 2020-12-19 21:42, reason: User, GCodes spinning, available RAM 130216, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0xffffffff Task Linu Error status: 0x00 MCU temperature: min 29.8, current 32.6, max 44.8 Supply voltage: min 23.8, current 24.0, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0 Driver 0: position 0, standstill, reads 23239, writes 31 timeouts 0, SG min/max 0/246 Driver 1: position 0, standstill, reads 23239, writes 31 timeouts 0, SG min/max 0/245 Driver 2: position 11388, standstill, reads 23238, writes 33 timeouts 0, SG min/max 0/795 Driver 3: position 0, standstill, reads 23239, writes 33 timeouts 0, SG min/max 0/1023 Driver 4: position 0, standstill, reads 23240, writes 33 timeouts 0, SG min/max 0/1023 Driver 5: position 0, standstill, reads 23248, writes 25 timeouts 0, SG min/max 0/316 Date/time: 2020-12-19 22:18:49 Slowest loop: 226.34ms; fastest: 0.07ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === FreeDm 375 (min 359), maxWait 99384ms, bed compensation in use: mesh, comp offset -0.670 === MainDDARing === Scheduled moves 6, completed moves 6, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 15], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = 2 -1 -1 -1 Heater 0 is on, I-accum = 0.2 Heater 1 is on, I-accum = 0.0 Heater 2 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue* is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause* is idle in state(s) 0 Code queue is empty. === Filament sensors === Extruder 0: no data received === CAN === Messages queued 9636, send timeouts 0, received 27395, lost 0, longest wait 2ms for reply type 6049, free buffers 47 === SBC interface === State: 0, failed transfers: 0 Last transfer: 19ms ago RX/TX seq numbers: 12458/12459 SPI underruns 0, overruns 0 Number of disconnects: 0, IAP RAM available 0x2098c Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.2.0-beta4 Code buffer space: 4096 Configured SPI speed: 8000000 Hz Full transfers per second: 35.64 File /opt/dsf/sd/gcodes/CFFFP_20mm_calibration_cube.gcode is selected, paused 19.12.2020, 22:18:28 Printing paused at X0.0 Y0.0 Z10.0 19.12.2020, 22:18:11 M32 "0:/gcodes/CFFFP_20mm_calibration_cube.gcode" File 0:/gcodes/CFFFP_20mm_calibration_cube.gcode selected for printingtoolboard:

m122 b121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.2-beta4.1 (2020-12-03) Bootloader ID: SAMC21 bootloader version 2.1 (2020-11-03b2) Never used RAM 4180, free system stack 72 words HEAT 50 CanAsync 85 CanRecv 83 TMC 54 MAIN 216 AIN 64 Last reset 00:39:01 ago, cause: software Last software reset data not available Driver 0: position 0, 830.0 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 1, ifcnt 32, reads 56493, writes 12, timeouts 0, DMA errors 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0 No step interrupt scheduled VIN: 23.9V MCU temperature: min 34.5C, current 46.9C, max 51.0C Ticks since heat task active 19, ADC conversions started 2331952, completed 2331951, timed out 0 Last sensors broadcast 0x00000002 found 1 24 ticks ago, loop time 0 CAN messages queued 29030, send timeouts 0, received 21901, lost 0, free buffers 36config.g :

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"vcore" ; set printer name M669 K1 ; select CoreXY mode ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards M569 P0.1 S1 ; physical drive 0.1 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.5 goes forwards M569 P0.4 S0 ; physical drive 0.5 goes forwards M569 P0.5 S0 ; physical drive 0.5 goes forwards M584 X0.0 Y0.1 Z0.2:0.3:0.4 E0.5 ; set drive mapping ; configure microstepping without interpolation M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z800.00 E830.00 ; set steps per mm M566 X3000.00 Y3000.00 Z60.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E250.00 ; set accelerations (mm/s^2) M906 X1900 Y1900 Z1900 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M671 X0:200:400 Y50:385:50 S10 ; Position of Leadscrews ;Duet Laser Filament Monitor ;M591 D0 P5 C"io3.in" R30:130 E3.0 S0 ; Tolerance 30 to 130%, 3mm comparison length, diabled ; Pressure Advance Tuning ;M572 D0 S0.1 ; Extruder pressure advance ; Cancel Ringing at the defined Freuquenzy ;M593 F40.5 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X410 Y385 Z390 S0 ; set axis maxima ; Endstops M574 X1 S1 P"121.io2.in" ; configure active-high endstop for low end on X via pin 121.io2.in M574 Y1 S1 P"io0.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z2 S2 ; configure Z-probe endstop for high end on Z ; Z-Probe M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"121.io0.in" H8 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height M557 X38:410 Y15:385 S75 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"121.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S500 ; set temperature limit for heater 1 to 500C M308 S2 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp1 M950 H2 C"out1" T2 ; create chamber heater output on out1 and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for the chamber heater and set PWM limit M141 H2 ; map chamber to heater 2 M143 H2 S120 ; set temperature limit for heater 2 to 120C ; Heater Model Parameters M307 H0 R0.641 C945.3 D3.18 S1.00 V24.1 ; PID Parameters Heated Bed M307 H1 R2.770 C158.7 D5.63 S1.00 V24.0 ; PID Parameter Mosquito Magnum M307 H2 A202.7 C76.2 D3.1 S1.0 V24.0 B0 ; PID Parameters Build Chamber ; Fans M950 F0 C"121.out2" Q500 ; create fan 0 on pin 121.out2 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"121.out1" Q500 ; create fan 1 on pin 121.out1 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 S"mosquito magnum" D0 H1 F0:1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M912 P0 S-14.8 ; Miscellaneous T0 ; select first tool ;M280 P0 S60 ; BLtouch - toggle switch mode ;G4 P1000 ; wait 1 second ;M280 P0 S120 ; BLtouch toggle self-test -

can you move the extruder connection to the expansion board?

-

@Veti i think that message was generated by the interpolation settings.

I changed yesterday only the following line:

M350 X16 Y16 Z16 E16 I1to

M350 X16 Y16 Z16 I1 M350 E16 I0after that change, the message was gone.

i could try it as a test, but I don't have printed the motor mount for the direct drive setup

-

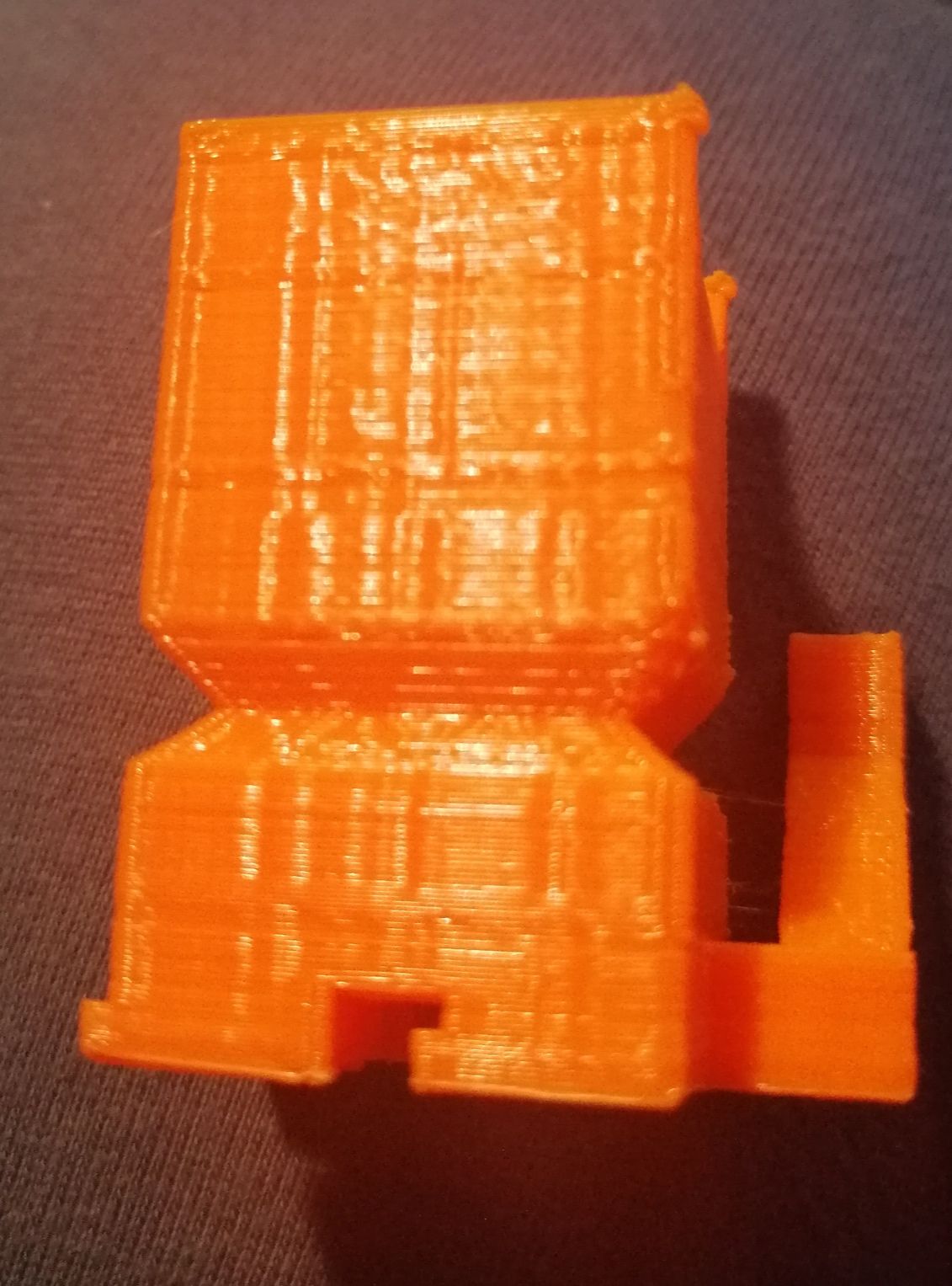

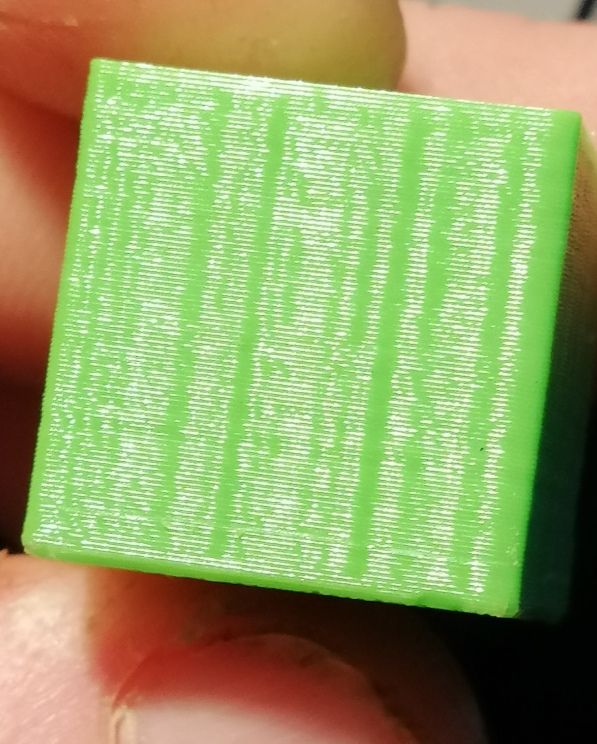

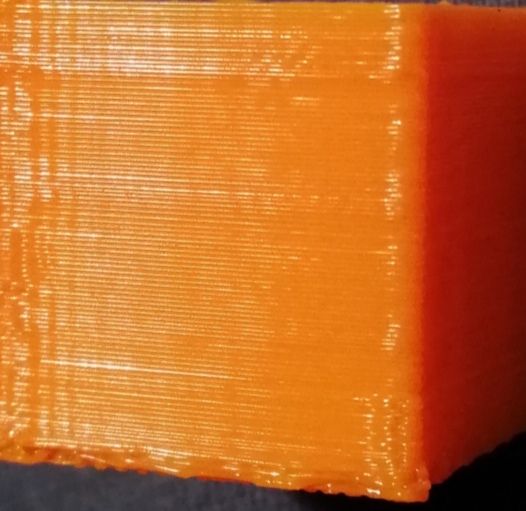

I printed a test cube to see if now everything is work g as it should,

This is my second or third print with petg.

What could cause these stripes?

Max instantaneous speed change x+y=1000

Max acceleration x+y=750

I played a little bit with the settings, but I think it isn't speed related? Perhaps some small mechanical problems? But I can't find them

-

could be belt on smooth pulley

damaged bearing

1.8 stepper artefacthard to tell

-

@Veti right now I have only 0.9 degree steppers on the machine. I have 2 flat pullys on the teethed belt side. But the kit was shipped like that

Do you think that is the problem ?

I checked the bearings. They are all good. The Machine has printed perhaps 15 hours after I finished the build

Could be the belt tension also play a role?

What do you think is a good starting point?Ive read somewhere that ok a CoreXY it should sound a little bit like a low guitar string. Around 60-80 hz?

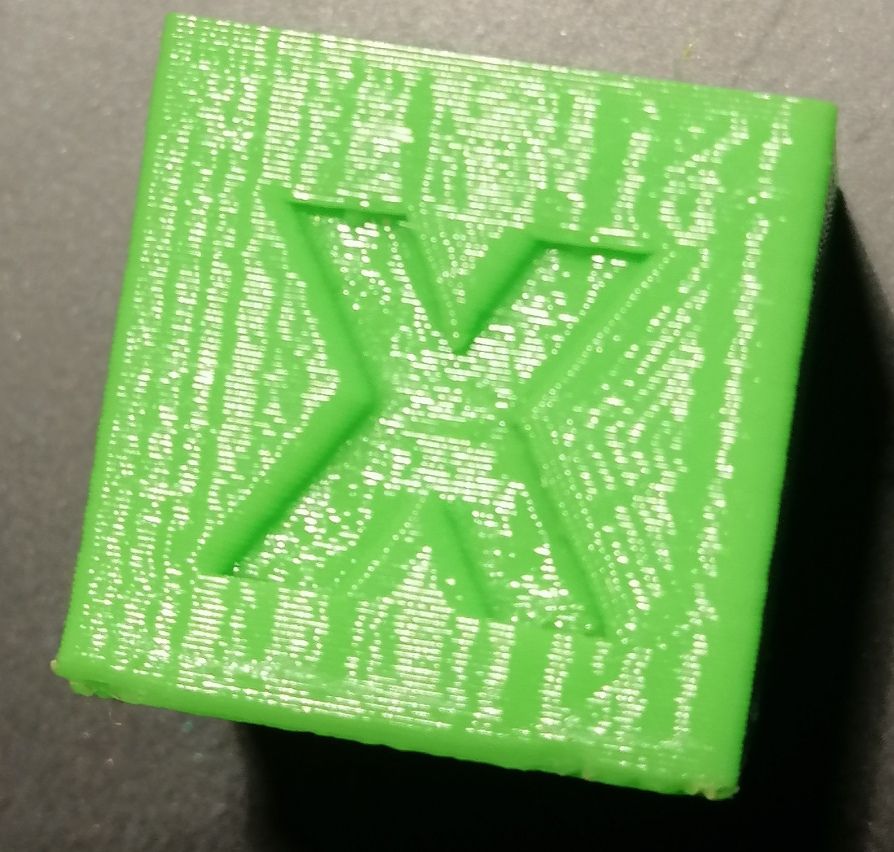

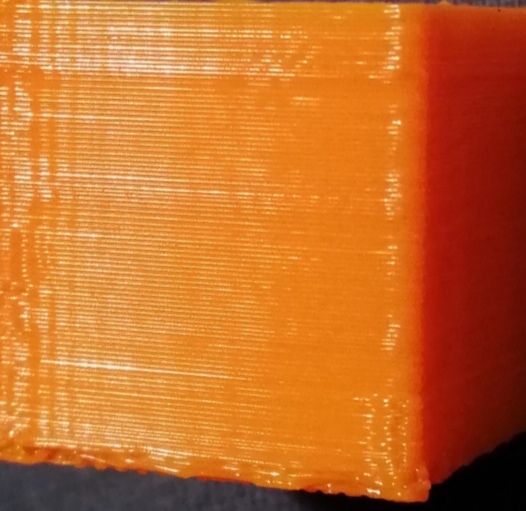

I tested now with pla and the same speed settings, but switched from cura 4.8 to prusa slicer.

It looks a lot better. Perhaps the slicer profile has wrong settings or other config issue

-

try changing the belt tension and see if that changes the pattern

-

-

@Veti

Now with the same speed settings, just sliced in prusa slicer. The other was cura 4.8Perhaps its a wrong slicer setting

I didn't change other parameters.

Could it be the infill that causes this thin lines? It had 20% infill, th spaces between the lines are matching the infill lines really close

-

yes it could be infill causing the pattern.

-

@Veti it was the infill ! / slicer settings. 2 additional Wall Perimeters solved the issue