Calibration Routine for Dual Extruder printers

-

Hey guys,

I want to create a calibration routine for the IDEX and LiftingHotend printers I develope together with @CR3D .

I already asked here, but I think that was the wrong category.

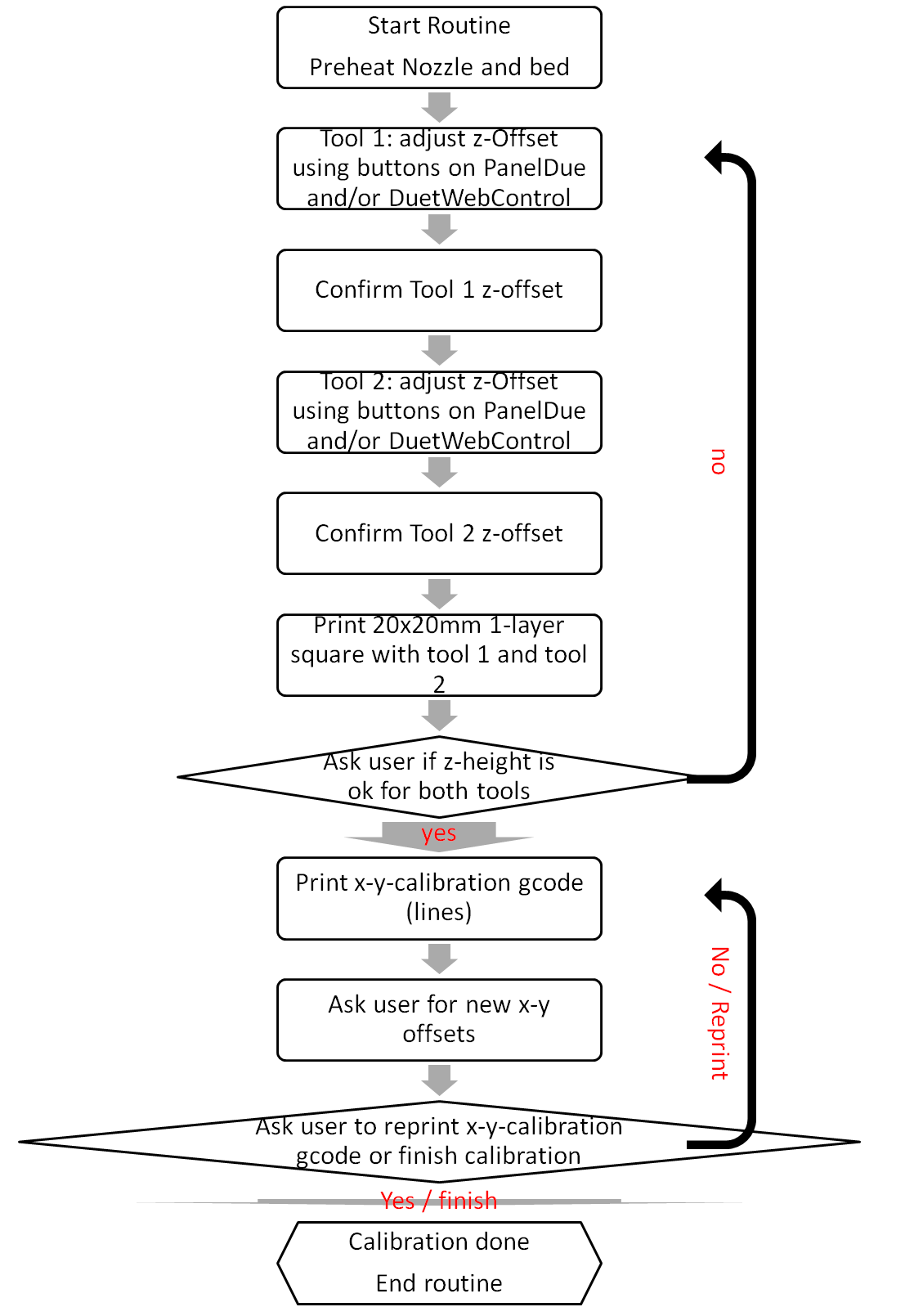

https://forum.duet3d.com/topic/21737/rrf3-dual-extruder-calibration-tool-and-nozzle-offset/5?_=1614279002208For this I want to "built" a routine which shall work like the following diagram:

I have multiple issues at the moment - I added my code below:

- Is it possible to make a "loop" that waits for user Interaction? I.e. if the z-height is ok? yes: continue, no: repeat certain part of code.

- What is the proper way to store the tool offset? M500 only store coorinate system offsets. I thought of writing to files (The M28 commands starting in line 28). The problem is: the content of the file then is :

G10 P1 Z{-axes[3].position}But I want it to be

G10 P1 Z-2.2Additionally these files are generated in the /gcode folder. I want them to be hidden or inside the macro folder so the user does not accidentally delete them.

3. Is there a way to ask / query the firmware if filament is loaded. Primarly I want to ask the firmware, if the filament runout sensor is triggerd. I really don't know how to "properly" use the object model...maybe it is in there and I am just blind...; add tool1offset_z.g and tool2offset_z.g to config.g with M98 P"tool1offset_z.g" M98 P"tool2offset_z.g" ; built z-calibration gcode - 20x20 square ; built x-y-calibration gcode M291 P"This will reset all previous defined tool offsets to the default values. Do you want to continue?" R"Calibration of Tool Offsets" S3 ;M561 ; clear any bed transform G28 M104 S215 T1 ; active & standby Temperature for Tool 1 200°C M104 S215 T2 ; active & standby Temperature for Tool 2 200°C M140 S65 ; set Bed Temperature to 65°C G10 P1 X-10 Y0 Z0 ; set Tool 1 offsets to default values G10 P2 X10 Y0 Z0 ; set Tool 1 offsets to default values G1 Z5 ; check if Filament is loaded in tool 1 ;if FILAMENT_LOADED_T1 == TRUE Then ;ELSE ;T1 ;M701 S"PLA" ; chek if Filament is loaded in tool 2 ;if FILAMENT_LOADED_T2 == TRUE Then ;ELSE ;T2 ;M701 S"PLA" ; start z-calibration routine ;##marker-mc-markface M291 P"Put a piece of Paper on the built plate" R"Calibration of z-Position" S2 T1 M291 P"Move the Bed up using the buttons until the paper slightly graps on the nozzle" R"Calibration of z-Position- Tool 1" S3 X0 Y0 Z1 M28 tool1offset_z.g ; generate file for z-offset Tool1 G10 P1 Z{-axes[3].position} ; set z-offset of Tool1 to value from last calibration M29 G1 Z5 T2 M291 P"Move the Bed up using the buttons until the paper slightly graps on the nozzle" R"Calibration of z-Position- Tool 2" S3 X0 Y0 Z1 M28 tool2offset_z.g ; generate file for z-offset Tool1 G10 P2 Z{-axes[3].position} ; set z-offset of Tool2 to value from last calibration M29 G1 Z5 M291 P"Remove Piece of Paper" R"Calibration of z-Position" S2 ; start test print for z-calibration ;M98 P"z_test_print.g" ; Print z-calibration lines ; ask user if he is satisfied ;If-Statement to ask user if z-offset is fine or z-calibration has to re-run, for rerun re_turn to ##marker-mc-markface ;start xy offset calibration ; to come....Thank you for your help. I think together we might be able to built a routin that will every dual extruder printer which uses RRF.

Stay safe.

Max