Hey guys,

a few month back I have posted about creating a macro to toggle LEDs on or off

old post

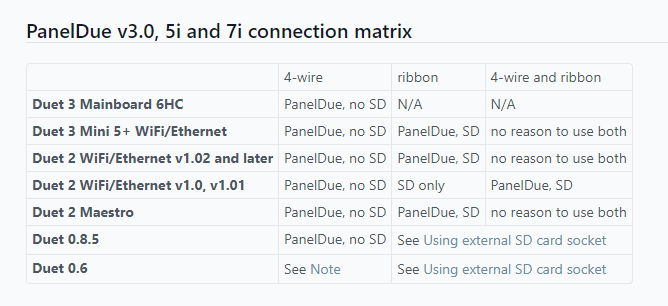

This works fine. Now I want to reuse this code for an RGB LED (neopixel strip with 21 leds) wired to my Duet Mini 5+. I can configure the state of the LED without any problem and set colours I want. But I want a "simple" button on the PanelDue to switch them off and back on.

I just couldn't find the appropriate part of the object model - or is this just a part that is missing?

if state.GIVE_ME_LED_BRIGHNESS_LEVEL == 1

M150 S21 P0

else

M150 S21 P255

A workaround for this would be to create a global variable but I think I missunderstood the concept for this. I tried to use:

global LED_state = true ; LED is on

or

global LED_state = 1 ; LED is on

Then I modified the "code" above to:

if LED_state == 1 ; or true if bool

M150 S21 P0

else

M150 S21 P255

But the DWC alway responds that the variable does not exist. Any idea on how to bugfix this? Maybe I am just missing a small puzzle piece again.

Thanks for your help.

Max