Two Z-step motors parallel serially wired or two drivers?

-

Hello I'm not sure how to connect my two Z-stepper motors to Duet.3.

Have two 1,33a stepper motors, according to instructions should I wire them in series, but the duet.3 has 6 drivers why not for each single Z-step engine a diver?Manual.

duet3d.dozuki.com/Wiki

„If you have two Z stepper motors, then for the types of motors commonly used in RepRaps (i.e. with rated current in the 1.2 to 2.0A range), it is better to connect them in series than in parallel.My questions are:

1. Serial or every stepper motor gets a driver?

2. Serial circuit better Since no step losses are possible?

3. Serial circuit is safer there are both faults and not a continuing?

4. If over 2,0A then back in parallel loud according to the instructions?Am grateful for each proposal and explanation.

Greeting TORX_1

-

As Duet 3 MB6HC does not provide dual Z motor outputs, then if you don't otherwise need to use all 6 drivers, I suggest you connect the Z motors to individual drivers. It will also allow you to do gantry levelling if you have either a Z probe or dual Z endstop switches.

-

Thanks for the answer to worry less, and no solder work to wire stepper motors serially.

Connect a Z-stop, and a synchronization belt between the two Z axes.

Thanks for the help.Greetings Torx_1

-

It need not be as complicated as that. If you have a z probe you can level them with this.

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

-

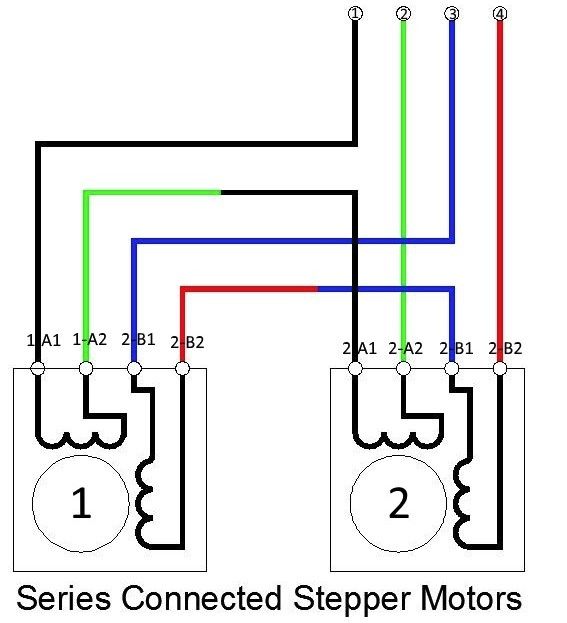

My question was, if it is so OK to connect the two Z-stepper motors in Series, to a driver? (As in the picture) 1,33a has a stepper motor.

At duet3d.dozuki.com/Wiki it is recommended to do it.

„If you have two Z stepper motors, then for the types of motors commonly used in RepRaps (i.e. with rated current in the 1.2 to 2.0A range), it is better to connect them in series than in parallel.

Or, however, as recommended by DC42, to two drivers, but I do not realize when a motor fails because a Z synchronous belt is installed.

I might be awkward with my question, grateful for any help.

Greeting. -

Yes you can connect them in series if you wish, but if you have a spare driver that's a better solution.

It's pretty rare for a motor or driver to fail in normal usage, so I don't think it's worth considering on whether to use a separate driver or not.

You also wouldn't need to belt them together at all since they each have a driver. You don't need the belt to keep them in sync because you can re-synchronize them easily with the probe or endstop.

-

@TORX_1 see answer here about series wiring vs parallel wiring of stepper motors: https://forum.duet3d.com/post/167111

If you have a belt synchronising the two motors, I wouldn’t advise having them on separate drivers; when motors are enabled, they jump to the nearest full step. If the motors are wired together (series or parallel) this should be the same step, but if wired to separate drivers, this might be different steps, and motors may eventually go out of synchronisation.

Ian

-

Thank you for your help helped me a lot.

I build a Cartesian printer with moving printed bed, the portal is pretty backlash-free, a switch is pressed and the second maybe 0.5 mm later, the backlash of the thread spindle is overcome, and then the portal slightly clamped to the switches come.

At the Z-synchronous timing belt and a single Z-stop, the spindle nut always remain on the same side of the thread when the switch is triggered, once set it always so.

With a Corexy, of course, the two Z-stop design is the better way.

Greetings Torx_1