Wierd pattern in heightmap indicates loose parts ?

-

Using the G32 ( bed.g) , and G29 from the configurator gave a hint of a non-realistic flatness of the borosilicate glass bed for my delta, RostockMax 3.2 equivalent, Duet 2.0, & SE300. The origin of the machine is a 3.0.

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.2.2 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2021-02-11

The stock probing pattern is an out-n-back zig-zag pattern. This then shows the much talked about alternating high and low ridges in the visualization.

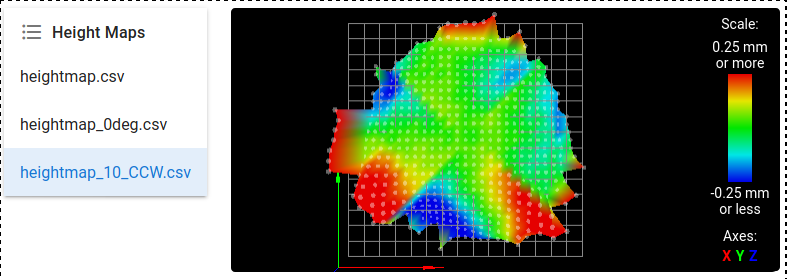

Rotating the glass 90 degrees, does not rotate the ridges. This has led me to consider that the glass is fine but start looking for loose parts, belts, joints, etc.I wrote a custom G30 macro which has a 10 mm grid. But rather than the out-n-back sequence of probing, I chose to use a square spiral CCW, which changes the pattern to a new artifact.

This probing sequence was to match the observed first layer problems of a large square box, where the turns are over extruded, followed by after turn, a too close to the glass causing back pressure on the extruder, which eventually is released as the height error normalizes.

Repeating the same ( or any ) probing profile many times has a 0.037 mm max deviation from a prior runs for each of the 579 probe points. So the repeatability is excellent, and what ever impact the 'looseness' imparts is consistent.

The map has a strong diagonal component which is the change in direction of the probe sequence. Upon turning, the reported probe height drops for each quadrant of the spiral.

So now for the question.

What are the likely suspects to replace, tighten, etc.?

Number of points: 579 Probing radius: 135 mm Probe area: 573.4 cm² Maximum deviations: -0.548 / 0.676 mm Mean error: 0.007 mm RMS error: 0.172 mm -

If you search the forum for delta backlash or delta ridges you will find some similar problems and maybe give you an idea on how they were solved.

@louvanna said in Wierd pattern in heightmap indicates loose parts ?:

This has led me to consider that the glass is fine but start looking for loose parts, belts, joints, etc.

Basically, yes.

-

First candidate in, 'What is loose?'

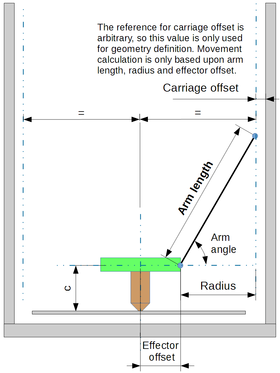

The three tower skates have assemblies of four bearing&wheels about the 't-slot' extrusion tower. The there is an axial displacement of approximately 1 mm for one of two wheels nearest the delta arm ball mounts . The lower wheel pair and the third are without play.

I have not yet done the math, but this would look like a change in radius for one of two arms of one tower. The other tower skates are have less movement, but noticeable.

I will be placing a shim washer, temporarily to see how much impact this has on the overall inaccuracy. Replacement/improved parts are on order.

-

Update on axial play in the carrier/skate bearing/wheel.

The axial play is not in the skate/carrier assembly but rather in the bearing itself. Therefore no shimming will be effective. So, waiting for the shipment of parts before any advancements on this aspect of a precision machine.

While I'm waiting for parts. Candidate #2,

Ball joint looseness, is so small it is not measurable. The total linkage of effector,ball,arm,ball,carrier/skate has a change in length <10um under pull/push forces.

Since this is an original kit from 2017, wear could be anticipated. The original effector is now a new SE300 to be compatible with the Duet electronics. It has the AL ball mounts. The rest is original RostockMax3.0 composite arms, original balls at the carrier/skate.

It is doubtful that this small or immeasurable play is a contributor to my problems.Anyone take issue in my conclusion on candidate #2 ?

-

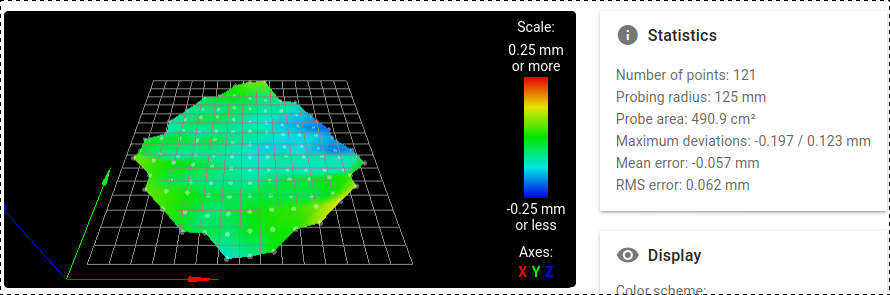

New bearings arrived from the parts order.

Five of 12 bearings in the three tower skates/carriages had noticeable play. I replaced all 12, as they are not terribly expensive, $0.75 ea. The new height map using the stock "_First Probe" macro which runs both G32 and G29 on a heated bed, resulted in the following heightmap.csv

-120.00,120.10,-120.00,120.10,125.00,20.00,20.00,13,13

0, 0, 0, 0, 0, -0.113, -0.076, -0.008, 0, 0, 0, 0, 0

0, 0, 0, -0.026, -0.036, -0.061, -0.013, 0.009, 0.012, 0.097, 0, 0, 0

0, 0, 0.031, -0.017, -0.072, -0.041, -0.013, 0.015, 0.027, 0.060, 0.123, 0, 0

0, 0.052, 0.029, 0.008, -0.024, -0.039, -0.037, -0.034, -0.039, -0.037, -0.001, 0.094, 0

0, 0.028, -0.040, -0.059, -0.077, -0.067, -0.078, -0.043, -0.029, -0.022, -0.004, 0.028, 0

0.063, 0.028, 0.001, -0.016, -0.044, -0.075, -0.101, -0.096, -0.099, -0.105, -0.103, -0.101, -0.000

-0.016, -0.072, -0.095, -0.083, -0.088, -0.100, -0.111, -0.099, -0.085, -0.102, -0.090, -0.102, -0.088

-0.028, -0.021, -0.022, -0.045, -0.037, -0.079, -0.102, -0.140, -0.138, -0.130, -0.158, -0.185, -0.172

0, -0.104, -0.072, -0.101, -0.078, -0.087, -0.075, -0.097, -0.121, -0.133, -0.137, -0.164, 0

0, -0.089, -0.071, -0.036, -0.036, -0.067, -0.103, -0.116, -0.145, -0.158, -0.182, -0.197, 0

0, 0, -0.071, -0.072, -0.075, -0.046, -0.058, -0.090, -0.088, -0.138, -0.159, 0, 0

0, 0, 0, -0.034, -0.011, -0.010, -0.048, -0.073, -0.075, -0.096, 0, 0, 0

0, 0, 0, 0, 0, 0.011, 0.058, 0.061, 0, 0, 0, 0, 0The third candidate, belts, were deemed adequately tensioned, and this heightmap suggests that to be a proper conclusion.

This looks to be just a wear-out scenario. The machine had 2500 hours of usage.

-

Looks like you got it sorted.