HELP! Duet 2 WiFi Configuration and DWC Upload???

-

After the S1 to S2 change, I homed Z, and other than it being a little rough, it's homed.

-I had to lift the bed until it was about 1mm below the endstop so when it started to home it would reach it before going the opposite way slowly to the bottom crashing into the shaft coupler leading to a push of the E Stop.

-So as long as it's ok that it did that then we're all set

-The bed is still super far from the nozzle after being homed

*If I lower the screw on the bed, that ultimately hits the endstop would it naturally fix itself later?What's next after homing? Just jog a little or do a test print?

Thanks,

-Carson

-

So after jogging for a little bit I'm noticing that Z thinks its at the bottom of the bed at 6mm and wont go any further down then that.

These are the numbers I got based on maxing out each axis. It looks like x and y are set at 235mm. And since I know its 300mm down the lead screw that's how I came up with that variable.

X=-4

Y=-3

Z=+294 -

I’ll play around with some of the Z values and see what happens and then I’ll try to follow one of the guides, but if I run into more issues I’ll definitely need your help.

Thanks,

-Carson

-

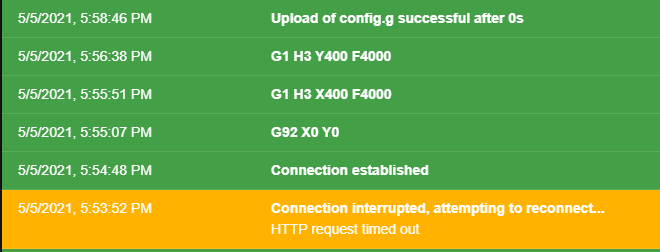

To get the sizing and coordinates of the print area correct you can use the following technique to measure and then change your config to make it permanent.

With the printer off, physically move the print head to the front left corner so that the nozzle is just over the corner of the printable area.

Turn the printer on and send G92 X0 Y0 because that's where we want 0,0 to be.

Now send

G1 H3 X400 F4000

That will move the print head to the right until the endstop is triggered. Check the X position in DWC and make a note of it. This will be your M208 X maxima value.Now send

G1 H3 Y400. That will move Y to the endstop. Check your Y position in DWC That will be the M208 Y maxima value.Put those values into config.g M208 command for X and Y.

M208 X235 Y235 Z310 S0 ; set axis maximaFor Z we can kind of do a similar test. But it sounds like when the endstop is triggering your nozzle is still quite far from the bed surface? If that's the case, you'll need to adjust the endstop position so that it's triggering when the nozzle is just above the bed surface. If the bed mount has spring leveling knobs you can balance the tension there as well to raise and lower the bed slightly. I'm not super familiar with the Ender5, but if it's anything like other creality printers it will have some adjustment knobs. I suggest tightening them all the way down at first and then backing them off one turn each. Then adjust the endstop position so that the nozzle can touch the bed.

See here for some bed leveling guidance. https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

Once you have the nozzle just touching the bed, send G92 Z0 to make it homed. Then jog it in the Z+ direction as far as you can. It should get pretty close to what you expect. Maybe not quite 300mm though.

-

Ok. So.

-X and Y are great. homed. boom.

-Z on the other hand is still giving me problems...So I referred to the guide and did exactly what it said and then Z would not move down or up.

Also, did you mean to say Z- instead of Z+

"Once you have the nozzle just touching the bed, send G92 Z0 to make it homed. Then jog it in the Z+ direction as far as you can. It should get pretty close to what you expect. Maybe not quite 300mm though."Because if I get the bed as close to the nozzle as I can and then do G92 Z0, Z+ is like 2mm up.

And that's kind of the problem I'm running into. If I zero Z at the top and home it, it initially works fine but then I try to jog down and it wont go anywhere and will only go up a few mm.(I think it won't go down because it thinks its all the way at the bottom)

I also tried G92 Z0 with the bed at the bottom and tried to home it. It went up a few mm then came down again violently crashing into the bottom. E stop.

-Just for shits and giggles I Zeroed it at the bottom and manually jogged it to the top with the DWC controls until it got to the endstop at the top, and that's how I got my Z axis value of 305.00mm (310.00mm was the old value). so then I plugged that in the M208 in my config.g

-I did try homing it both with the old M208 value and the new one and the same thing happens.

-At one point I zeroed Y and then sent the G92 Z0 command and my Z axis wouldn't go up or down. I'm starting to get frustrated because 3x now I've dialed in the bed to the nozzle and every time it crashes I have to start all over. Plus I hate seeing my printer crash.

So, yeah, now I'm just confused, sorry.

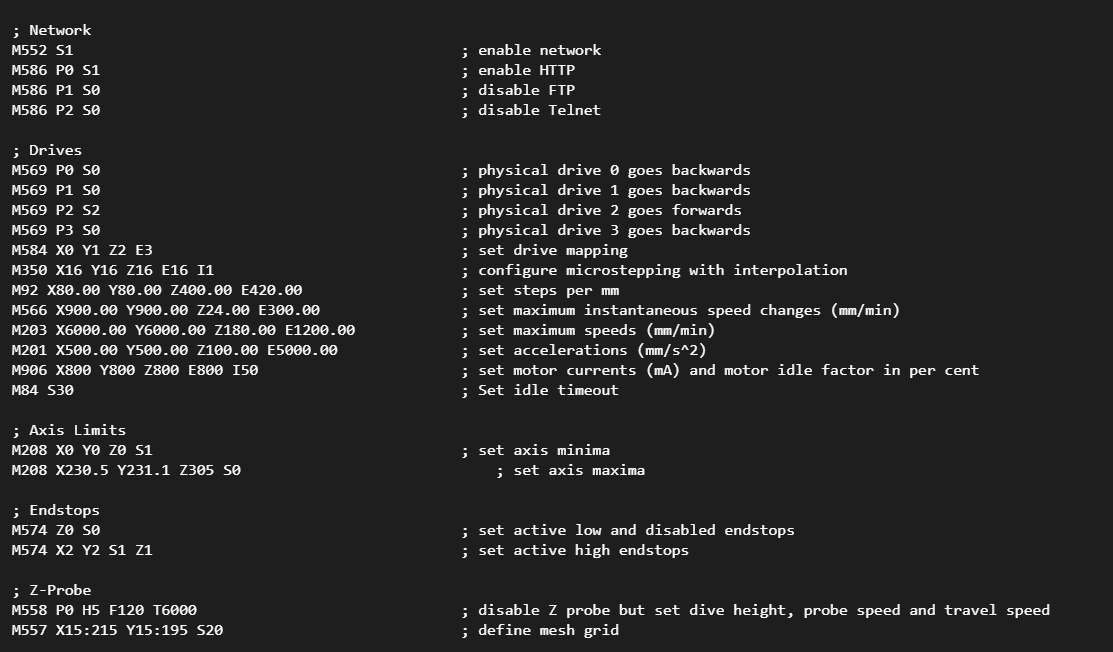

*Here are some pictures of all my files

Send G92 Z0, When it's up, like this:

Or down, like this?

Thanks,

-Carson

-

Z0 should be when the bed is touching the nozzle.

Z+ moves the bed down, away from the nozzle.

When the bed is at the bottom it would be at the ~300mm position.

The Z endstop is at the top side, right?

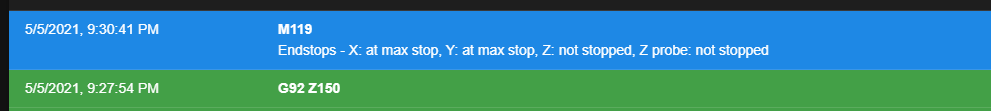

Send M119 and see what it says about the Z endstop. When nothing is pressing the endstop, it should say, "not triggered". And vice versa.

If you move the bed to the center of travel, so it's half way up and down, send G92 Z150. That will force it to be homed and at 150mm (even if it's not exactly). Now you should be able to use the jog buttons to move the bed up and down.

Does +Z move the bed down? Does -Z move the bed up?

If not, we need to change the Z motor direction.

-

Ok, I'll try that, but to answer your question, it moves up when I hit Z+

-

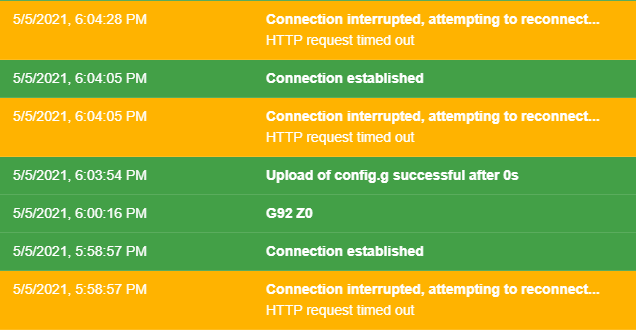

G92 Z150, said it was successfully executed, but literally nothing happened. hmm

-

-

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

Ok, I'll try that, but to answer your question, it moves up when I hit Z+

Then your z axis motor is turning the wrong direction.

Change the M569 P2 S0 to S1 (or vice versa if it's already S1)

G92 z150 won't do anything visible. It's just telling the firmware that the z axis is homed and at 150 so that you can move it freely with the jog buttons.

-

Ok. So.

-Everything is now homed, YAY!

-The Z was P2 S2, so that's probably why it was being so weird

-The only other problem is, whenever I turn on my printer, I end up having to home them again each time. Can it save my settings, or can we program it to home on start up? I'm pretty sure it homes itself before each print...but yeah. Or maybe that's how it's supposed to be?*I guess all that's left is fine tuning then, right? and then running whatever mesh compensation is??? Is it necessary, or do I need to install a BL Touch first before I can use that function?

Thanks,

-Carson

-

When the power is off or the motors time out and the current is reduced the position can no longer be guaranteed so the machine must be homed before you can move it again.

No it's not a good idea to home it as soon as power is applied. It may sound convenient but I'm pretty sure the first rule of automation safety is don't make something move suddenly when power is applied. User must initiate movement.

You'll need to setup the bltouch first before you can do mesh compensation or anything like that.

In the meantime you can level and clean the bed and try a test print.

Calibrating the extruder would be a good idea too.

-

Ok, yeah I'll calibrate the extruder and so forth and run a test print. Should I change any settings in Cura or in the config.g when switching from a Bowden setup to a *direct drive (*which I currently have on this one)? And do I change any settings in Cura because I'm on the duet board now?

Thank you so much for all your amazing help! Seriously, words cannot describe how grateful I am for your assistance so far! What can I do to thank you, for real? do you have a Patreon, or can I write a review? Let me know!

Big smiles over here! I'm not completely at the finish line yet but the hard part is over and I can see the checkered flags.

-Carson

-

Real quick. To be clear down for Z axis is Z+, Left for X is X-, and Front for Y is Y-?

Cuz that's what I have it as now.

I think I spoke too soon lol

-I ran a test where I had all 3 homed, then jogged all three to their centers and hit home all and the x and y were going to the wrong corner (left front instead of back right[where the endstops are]) should I go back in config.g and change some S0's to S1's?

-when the extruder head is in close proximity to the back right it seems to find the correct corner just fine when homed, but if I'm far away it crashes into the opposite corner.

-

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

Real quick. To be clear down for Z axis is Z+, Left for X is X-, and Front for Y is Y-?

Cuz that's what I have it as now.That is correct.

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

-I ran a test where I had all 3 homed, then jogged all three to their centers and hit home all and the x and y were going to the wrong corner (left front instead of back right[where the endstops are]) should I go back in config.g and change some S0's to S1's?

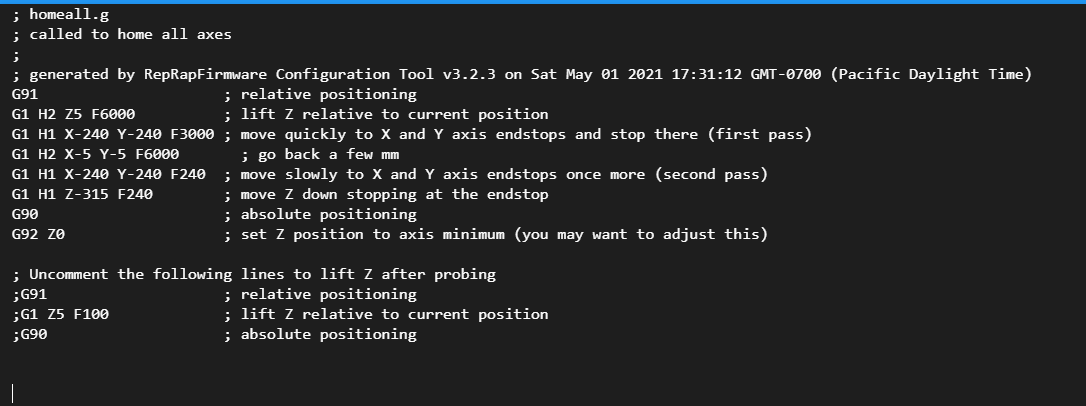

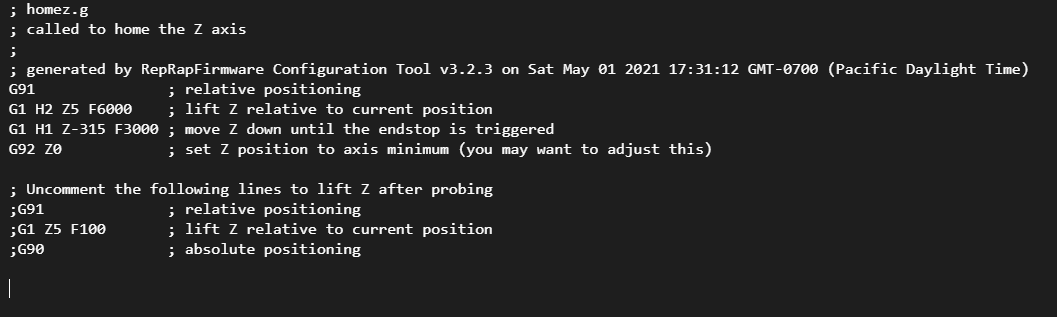

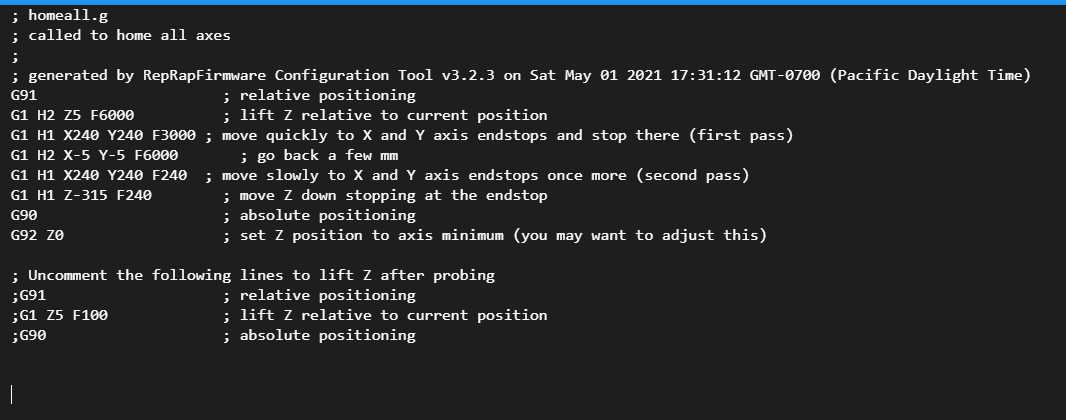

No, you'll need to change the homeall.g file as I posted above.

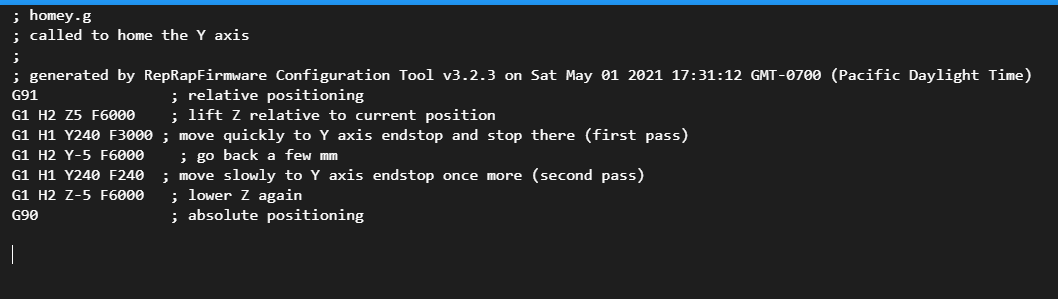

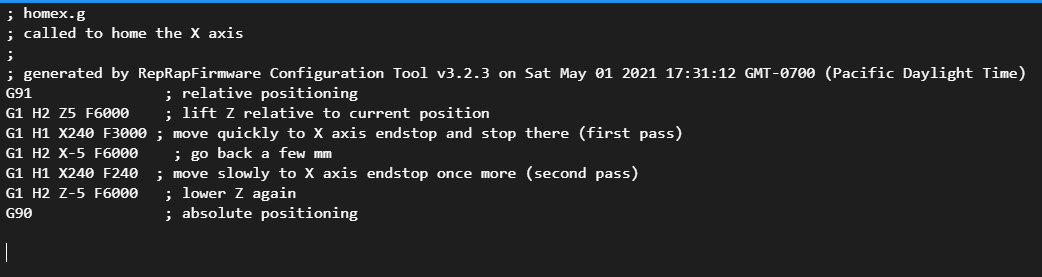

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 01 2021 17:31:12 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X240 Y240 F3000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X-5 Y-5 F6000 ; go back a few mm G1 H1 X240 Y240 F240 ; move slowly to X and Y axis endstops once more (second pass) G1 H1 Z-315 F240 ; move Z down stopping at the endstop G90 ; absolute positioningYou changed homex.g and homey.g already?

; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 01 2021 17:31:12 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X-5 F6000 ; go back a few mm G1 H1 X240 F240 ; move slowly to X axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 01 2021 17:31:12 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y240 F3000 ; move quickly to Y axis endstop and stop there (first pass) G1 H2 Y-5 F6000 ; go back a few mm G1 H1 Y240 F240 ; move slowly to Y axis endstop once more (second pass) G1 H2 Z-5 F6000 ; lower Z again G90@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

-when the extruder head is in close proximity to the back right it seems to find the correct corner just fine when homed, but if I'm far away it crashes into the opposite corner.

I'm not sure what you mean by that.

-

Ok, I changed those values and I rechecked each home (x,y,z) individually, and then Home All.

-Everything seems to be working normal now.

-I'll calibrate some things and run a test print.

Thanks,

-Carson

-

So, I'm trying to calibrate my E-steps, but it seems no matter how slow I try to set it, it goes fast, and no matter what length I set it to extrude, it seems to extrude forever until I eventually have to E stop it, so I don't waste filament .

The guide says to run G1 E100 F60, and 60mm/sec is pretty fast but I ran it anyway. But it says to set it low, so I manually hit 1mm/sec and to extrude 100mm and I got the same results for both...Fast and never ending filament extrusion.

-Not sure what to do

Thanks

-Carson

-

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

G1 E100 F60, and 60mm/sec

F60 is 60mm/min, so only 1mm/s which is slow.

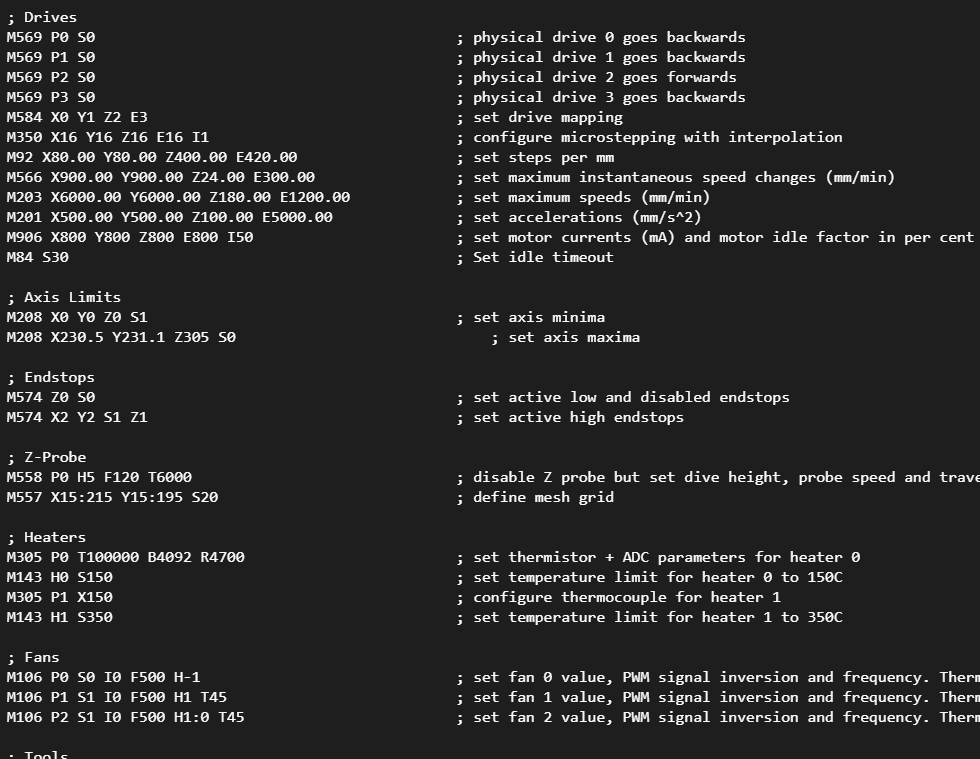

If it's still going very fast it could be that your steps per mm is very wrong from what it should be.

What is the extruder? The default creality bowden setup for the ender5?

M92 X80.00 Y80.00 Z400.00 E420.00

E420 could be quite wrong if it's teh stock. I think it would be more like E90

-

It's a Micro-Swiss All Metal Hotend Direct Drive.

But yeah it's going really fast. In about 15 sec i had like over 300mm. And it just keeps going and going.

-

@pcnoobneedsmajorhelp said in HELP! Duet 2 WiFi Configuration and DWC Upload???:

It's a Micro-Swiss All Metal Hotend Direct Drive

And what kind of motor on it? 200 or 400 steps per rotation?

Like this?

https://store.micro-swiss.com/products/micro-swiss-direct-drive-extruder