Duet WiFi Expansion Board. PMW Control of 80W Laser Module

-

I've heard very good feedbacks about this laser module and eventually decided to give it a try .

AliExpress 80w LAserIn Duet wiki is saying -

Note: if your system includes either a DueX expansion board or an expansion Breakout Board, then that board already includes this circuitry.So I'm attaching the +12v and ground of the laser to Duet 12v power supply

And PWM to PWM7 on Expansion board .

When the machine is Laser Mode (m452)- the laser is ON from the start. if I unplug the PWM - it's doesn't work.

If the ground cable is also connected to Expansion PWM7 ground - nothing happening...

; Configuration file for Duet WiFi (firmware version 3.3) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"M1" ; set printer name M669 ;K1 ;Set Cartesian mode ;M453 ; CNC Mode M452 C"exp.heater7" F250 ; Enable Laser mode, on exp.heater7, with max intensity being 255, and a PWM frequency of 200 ; Network M551 P"*****" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 R-1 ; physical drive 4 goes forwards ;------------------Y MOTOR------------------------------------------------------------- M569 P6 R1 T2.5:2.5:5:5 S1 M569 P7 R1 T2.5:2.5:5:5 S1 ; driver 6,7 direction is backwards and requires an active high enable, 5us minimum step pulse, 2.5us minimum step interval, 5us DIR setup, and 7.5us hold time ;-----------------Z MOTOR-------------------------------------------------------------- M569 P5 R1 T2.5:2.5:5:5 S1 ; driver 5 direction is backwards and requires an active high enable, 5us minimum step pulse, 2.5us minimum step interval, 5us DIR setup, and 7.5us hold time ;-----------------EXTRUDER 0 MOTOR----------------------------------------------------- ;M569 P9 S0 R1 T5:2.5:5:7.5 ; driver 9 direction is backwards and requires an active high enable, 5us minimum step pulse, 2.5us minimum step interval, 5us DIR setup, and 7.5us hold time M584 X0 Y6:7 Z5 U1 E3 ; set drive mapping to external drivers M350 X128 U128 M92 X640.00 Y171.00 Z5050.00 U640 E400.00 ;M92 X80.00 Y171.00 Z5050.00 U80 E400.00 ; set steps per mm M566 X2000.00 Y1300.00 U4000 Z60.00 E800.00 ; set maximum instantaneous speed changes (mm/min) M203 X4000.00 Y4000.00 U21000 Z300.00 E1000.00 ; set maximum speeds (mm/min) M201 X600.00 Y600.00 U4500 Z80.00 E900 ; set accelerations (mm/s^2) M906 X1000 Y1200 Z600 U1200 E760 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 U0 Z-30 S1 ; set axis minima M208 X1019.5 Y790 U800 Z550 S0 ; set axis maxima ; Endstops M574 X2 S1 P"!xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin xstop M574 Y1 S1 P"!ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop M574 Z1 S1 P"!zstop" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin zstop M574 U1 S1 P"!e1stop" ; configure switch-type (e.g. microswitch) endstop for low end on U via pin zstop ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:990 Y45:700 S60 ; define mesh grid ; Heaters M308 S1 P"e0temp" Y"thermistor" T100000 B4138 M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q100 ; create fan 0 on pin fan0 and set its frequency M106 P0 S1 R1 L15 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"Fan1" Q3300 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 L1 X1 B0.1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P2 S1 R1 L255 H1 ; Tools ''' Create a tool that uses the low end (X) carriage''' ;;M563 P0 S"Spindle" F0 ;R0 ; define tool 0 G10 P0 X0 Y0 Z0 S0 R0 ; set tool 0 axis offsets ; Configure Tool 0 as the CNC Spindle M950 R0 C"e1heat" Q2000 L0:12000 ; Create spindle index 0 with ; inverted PWM output on E0 heater pin ; and spindle speed of 12000 rpm at maximum PWM M563 P0 R0 S"Spindle" ; Create Tool 0 with Spindle 0 and call it Spindle G10 P0 X0 Y0 Z0 S0 R0 ; Set Tool 0 axis offsets M568 P0 F0 ; Set Tool 0 to default RPM of 0 T0 ; Select Tool 0 ''' Create a tool that uses the high end (U) carriage''' M563 P1 S"Extruder" D0 H1 X3 F2 ; define tool 0 ;G10 P1 Y-7.4 U-33.5 Z-17 G10 P1 Y7.5 Z-17 ; set tool 0 axis offsets G10 P1 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M575 P1 B57600 S1 - the laser is ON from the start. if I unplug the PWM - it's doesn't work.

-

@allsirius don't use "exp.heater7" in that command, use "duex.pwm5". Pin "exp.heater7" refers to the signal on the expansion bus, which is inverted because it is active low.

-

@dc42 Thank you for quick replay !

I guess I wasn't clear enough about my hardware setup:

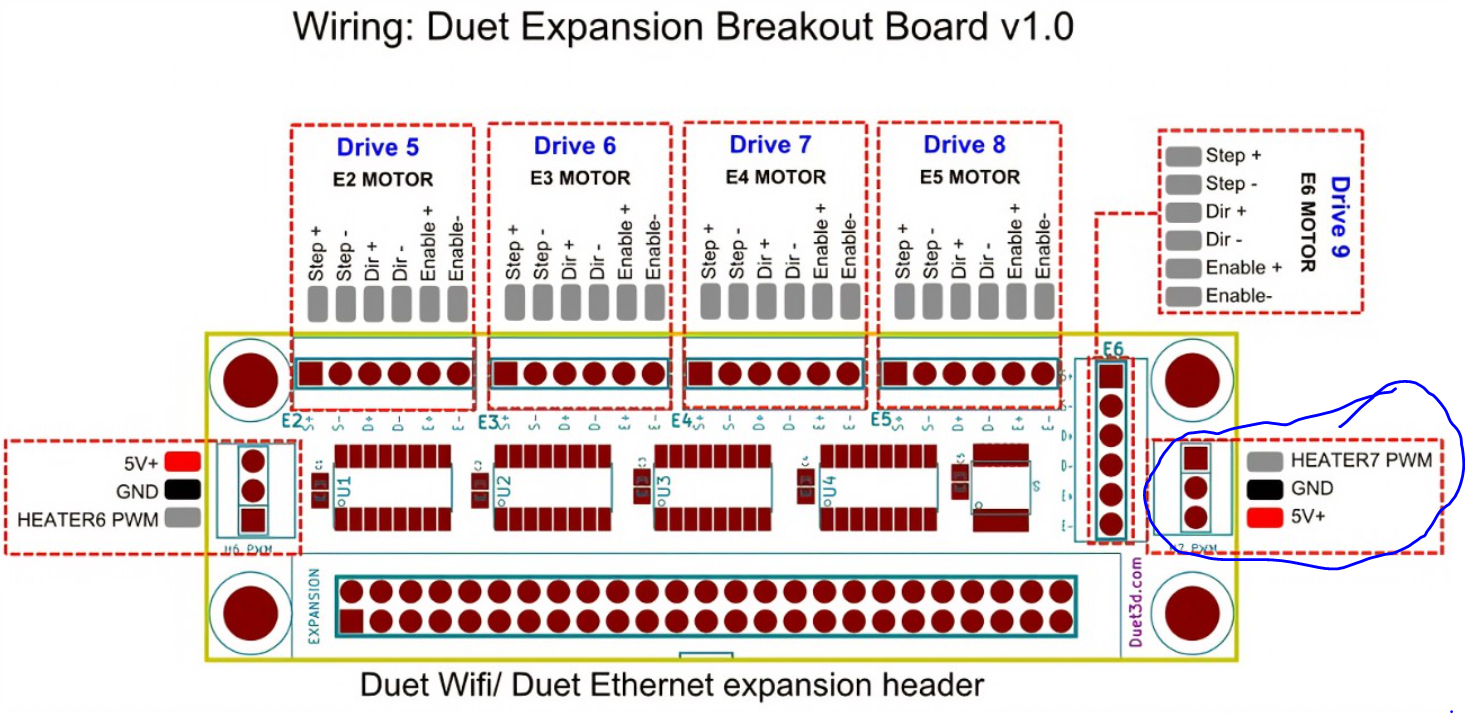

I'm using this port on Duet Expansion Breakout Board

And after I used M452 C"duex.pwm5" F250 command in my Config.g the laser is acting the same. Full power from the start and the fans on it are always on from the V+ and ground form my power supply , even I'm unplugging the PWM from the board.

So I think I'll need to power it from the third free Fan port on my Duet WiFi to avoid the spinning the Laser fans while it's not in work. -

@allsirius do not try to power the laser from a fan or heater port. If you that then you will probably damage the laser control module, the Duet port that it is connected to, or both.

Please provide a link to the documentation for that laser.

If you have a multimeter, please try removing the M452 line from config.g and disconnect the laser, then start the Duet and measure the voltage between the PWM output and ground. It should be 0V.

-

@dc42 Here is all what I've got about the laser ..

Laser Aliexpress link..... -

@allsirius I'm using more or less the same laser module, probably just another form factor: LaserTree LT-80W-LE-Mini

I first used it with this circuit: https://photos.app.goo.gl/i8Mxxm5eNJhgfwycA

But now I have switched to the one from the wiki.

What is missing in the wiki is the info that this circuit needs a inverted signal.

And according to the wiki page about the breakout board, this is true there as well.

The example to control a servo is: M950 S0 C"!exp.heater7"

So, you probably have to use it like this: M452 C"!exp.heater7" F250And to control the fan you have to cut the +12V supply to the module.

As dc42 said, you can't use heater and fan outputs. If i recall correctly, they switch the negative side (GND).

So you probably would need a separate relay or so to do this.