Temperatures totally wrong 3.4 RC

-

Good morning, after installing the latest RC FW version

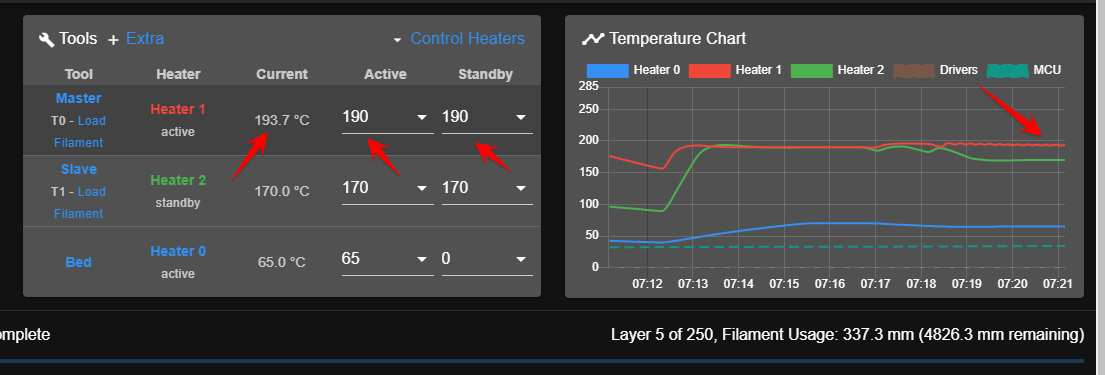

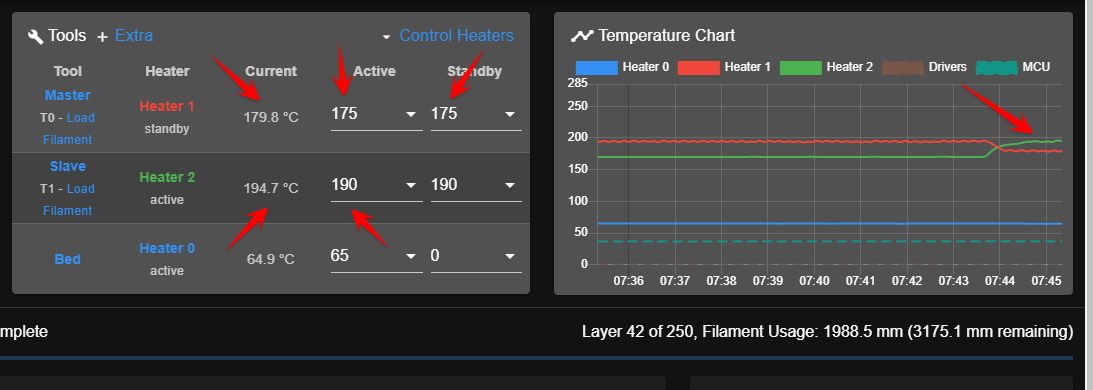

Board: Duet 2 WiFi (2WiFi) Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.0rc1 (2022-02-09) Duet WiFi Server Version: 1.26the tempearture control for both the extruders are totally out of control....as you can see I've setted a temperature of 190° for the active extruder but the temperature still keeps on be regulated by the PID at 195°C wich is the temperature I've setted for the first layer only.

I've noticed that this behavior starts after the first temperatue setting change...infact as you can see in the first pic the standby temperature for the Tool 1 is correctly maintained at 170, after the first tool change al the settings are gone....this happens even when printing with single tool, if I print the first layer with a temperature it's maintained correctly for the first layer but starting from the second layer on(when I usually drop it by 5°C) the issue appears:

Both the PIDs have been correctly setted....

M303 T0 S205 M303 T1 S205Is this a known issue for the latest fw version? Before installing the RC1 it all worked fine

Thanks

-

System referenced this topic

-

@thedragonlord It may not make any difference, but RC2 is the current latest firmware and your post shows you are running RC1. It might be worth trying the latest update. Also check that you have updated DWC to match the version of the firmware you are running.

When your tools are active do you have the part cooling fan running?

Can you post your config.g (plus your config-override.g if you use that for heater settings).

-

@gloomyandy said in Temperatures totally wrong:

@thedragonlord It may not make any difference, but RC2 is the current latest firmware and your post shows you are running RC1. It might be worth trying the latest update. Also check that you have updated DWC to match the version of the firmware you are running.

When your tools are active do you have the part cooling fan running?

Can you post your config.g (plus your config-override.g if you use that for heater settings).

I was thinking to install the RC2 but in another post here I've seen a user wich is experiencing a similar issue with RC2 :https://forum.duet3d.com/topic/27518/3-4-0beta7-rc2-overheating-when-the-model-fan-is-turned-on

When the tools are active I have the cooling fans on, yes.

Here's the .g files:

310; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.1.4 on Sun Nov 01 2020 08:34:36 GMT+0100 (Ora standard dell’Europa centrale) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"DragonCore" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S1 ; enable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes backwards M569 P1 S1 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes backwards M569 P4 S0 ; physical drive 4 goes backwards M584 X0 Y1 Z2 E3:4 ; set drive mapping M350 E16 I0 ; configure microstepping without interpolation M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation M92 X79.8 Y79.8 Z1188.11 E415:415 ; set steps per mm M566 X660.00 Y660.00 Z12.00 E5000:5000 ; set maximum instantaneous speed changes (mm/min) #################################### M203 X6000.00 Y6000.00 Z360.00 E5000.00:5000.00 ; set maximum speeds (mm/min) ############################ M201 X500.00 Y500.00 Z20.00 E5000.00:5000.00 ; set accelerations (mm/s^2) ############################### M906 X1200 Y1200 Z900 E500:500 I30 ; set motor currents (mA) and motor idle factor in per cent ###################################e M84 S30 ; Set idle timeout ; Axis Limits M208 X-20 Y-30 Z0 S1 ; set axis minima ################################ M208 X295 Y310 Z350 S0 ; set axis maxima ######################################### ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P9 C"^zprobe.in" H5 F300 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-9.329 Y23.85 Z1.397 ; set Z probe trigger value, offset and trigger height ############################################### M557 X-10:280 Y50:350 S40 ; define mesh grid ##################################################### ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 H12 L-5 R4200 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S285 ; set temperature limit for heater 1 to 280C M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 H13 L-5 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S285 ; set temperature limit for heater 2 to 280C ; Fans M950 F0 C"fan0" Q2000 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M308 S4 Y"mcu-temp" A"MCU" ; configure sensor 3 as thermistor on pin e1temp for left stepper M308 S3 Y"drivers" A"Drivers" ; configure sensor 4 as temperature warning and overheat flags on the TMC2660 on Duet M950 F2 C"fan2" Q2000 ; create fan 2 on pin fan2 and set its frequency M106 P2 H3:4 L0.5 X1 B1 T40:50 ; set fan 2 value ; ============================================= ; = WATER COOLING CONTROLLER = ; ============================================= M950 F10 C"exp.heater5" M106 P10 S1 H1:2 T51 ; ============================================= ; = LED FAN = ; ============================================= M950 F11 C"exp.heater4" M106 P11 S0 ; Tools M563 P0 S"Master" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"Slave" D1 H2 F0 ; define tool 1 G10 P1 X20 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M912 P0 S-2.45 ; calibrates CPU temp M501 ; load saved parameters from non-volatile memory ; ========================================================= ; = D R A G O N C O R E = ; ========================================================= ; ================== ; = VARIABLES = ; ================== global isPrinting = false global isActuallyPrinting = false global toolsSafeTemperature=50 global tool0ActiveTemperature=0 global tool1ActiveTemperature=0 global coolDownTemperature=20 global primingExtruderAmount=12 global purgingAmount=7 ; ================== ; = NOZZLES WIPING = ; ================== global XWipeEnterCoord=208 global YWipeEnterCoord=-19 global XWipeFinalCoord=47 global YWipeFinalCoord=-30 global leftNozzleAngle=17 global rightNozzleAngle=42 global middleWiperAngle=29 global leftMostWiperAngle=3 global rightMostWiperAngle=55 ; ================== ; = FOR PA SETTINGS= ; ================== ;global g_pa_setting = 0.15 ; the current pressure advance setting ;global g_pa_increment = 0.01 ; the amount to increment the pressure advance setting ;global g_pa_layer_count = 25 ; the number of layers to count to cause the incrementing of the pressure advance setting ;global g_pa_layer_counter = 0 ; the current layer count ; =================== ; = NOZZLES WIPER = ; =================== M950 S1 C"exp.heater6" Q50 ; ================== ; = SCREWS POINTS = ; ================== M671 X5:320:320:5 Y320:320:5:5 P0.5 ; point1 (5,320), point2 (320,320), point3 (320,5), point4 (5,5) ; ===================== ; = MAGNETIC SENSORS = ; ===================== ;M98 P"Print_gcodes/magnetic_filament_sensors.g" ; ===================== ; = ACCELEROMETER = ; ===================== M955 P0 C"spi.cs4+spi.cs3" I50 M593 P"ei2" F54.14 ; ====================== ; = POWER FAILURE = ;======================= M911 S21 R23 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; power failure; config-override.g file generated in response to M500 at 2022-02-26 06:05 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 R0.230 K0.161:0.000 D6.93 E1.00 S1.00 B0 M307 H1 R2.033 K0.194:0.179 D6.99 E1.35 S1.00 B0 V23.9 M307 H2 R1.889 K0.191:0.164 D8.45 E1.35 S1.00 B0 V23.9 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 -

@thedragonlord It looks like you may be doing something with temperature settings in your tool files (you have global variables which seem to relate to temperature settings) so you should probably post any files that set/change temperatures and explain what it is you are doing.

It may also be worth creating a simple test print (that only uses one tool ideally) and posting the gcode file for that print and a screenshot of the graph and the DWC temperature readings showing what happens. It may be worth using a larger temperature change from the first layer to the second layer so that it is more obvious what is going on (5 degrees can be hard to spot on a graph).

It is probably worth running M105 in a console at various stages to see how the values there compare with those displayed in DWC.

You may also want to experiment with turning your part cooling fan off to see if that is having any impact on this problem (recent versions of the firmware have introduced a feed forward mechanism that attempts to compensate for the impact the cooling fan can have).

Did you check that your DWC version matches the firmware?

-

Another data point: I also observe weird temp fluctuations with 3.4-rc1!

Initially I thought something on my machine is weird as I was changing filaments and nozzle... but now I see multiple other similar reports.I did zero changes to my config when I upgraded from 3.3 to 3.4-rc1...

I haven't had time yet to revert back and test again to rule out a hardware issue. -

@resam It would probably help the folks that are trying to diagnose any issues if you could provide details of what is happening and when.

-

@gloomyandy same symptoms as described by the original poster here.

Hotend temp fluctuations of 3-4°C, total offset of up to 5°C higher than the set temp during prints.I'm on a Duet2Wifi with SBC on 3.4-rc1, single hotend.

On 3.3, my temp readings were pretty stable within +/-0.5°C changes during a print. -

@resam Are you using a part cooling fan? Is there any correlation between the temperature changes and the use of the part cooling fan? If you rerun the PID tuning for the hotend using the RC1 build and then test again does anything change? Take care as you may not be able to use the new PID parameters with 3.3 if you want to go back to that, so make sure you save the old settings before replacing them with the RC1 version.

-

@gloomyandy said in Temperatures totally wrong:

@thedragonlord It looks like you may be doing something with temperature settings in your tool files (you have global variables which seem to relate to temperature settings) so you should probably post any files that set/change temperatures and explain what it is you are doing.

It may also be worth creating a simple test print (that only uses one tool ideally) and posting the gcode file for that print and a screenshot of the graph and the DWC temperature readings showing what happens. It may be worth using a larger temperature change from the first layer to the second layer so that it is more obvious what is going on (5 degrees can be hard to spot on a graph).

It is probably worth running M105 in a console at various stages to see how the values there compare with those displayed in DWC.

You may also want to experiment with turning your part cooling fan off to see if that is having any impact on this problem (recent versions of the firmware have introduced a feed forward mechanism that attempts to compensate for the impact the cooling fan can have).

Did you check that your DWC version matches the firmware?

As told in a next post all worked fine until I've installed RC1...DWC matches the firmware, yes...unfortunately I have no time to make all the checks you asked me before, I downgrade the FW and wait until all will be fixed.

-

@thedragonlord @resam the heater parameters changed in 3.4 beta 7; see https://docs.duet3d.com/en/User_manual/Reference/Gcodes/M307/

I can’t find the note about it in the release notes (@dc42 ?), but in 3.4RC2 try sending M307 H# and see what parameters are reported. Then retune with M303 and see if that helps. I did this the other day, and temps were very stable in 3.4RC2.

Ian

-

@droftarts said in Temperatures totally wrong:

@thedragonlord @resam the heater parameters changed in 3.4 beta 7; see https://docs.duet3d.com/en/User_manual/Reference/Gcodes/M307/

I can’t find the note about it in the release notes (@dc42 ?), but in 3.4RC2 try sending M307 H# and see what parameters are reported. Then retune with M303 and see if that helps. I did this the other day, and temps were very stable in 3.4RC2.

Ian

I don't understand....if I'm not wrong M307 reports the actual PID values but M303 recalculatte them so how the two comands are related? I mean, what's the purpose to run M307 H# to see the actual PID parameters if running a M303 T# then will completely recalculate them?

-

undefined Phaedrux moved this topic from General Discussion

undefined Phaedrux moved this topic from General Discussion

-

Still no solution for this issue???

-

@thedragonlord did you retune the heaters? Like I said, in any release since 3.4beta7, the parameters have changed, and I believe the algorithm to determine PID has too.

My suggestion was to see what values you had currently, retune, and see what parameters you then get.

I’ve asked @dc42 to look at this thread.

Ian

-

@droftarts said in Temperatures totally wrong 3.4 RC:

@thedragonlord did you retune the heaters? Like I said, in any release since 3.4beta7, the parameters have changed, and I believe the algorithm to determine PID has too.

My suggestion was to see what values you had currently, retune, and see what parameters you then get.

I’ve asked @dc42 to look at this thread.

Ian

I7ve followed your advice and I've watched the values I had with M307 then retuned with M303, got different values but the issue are still "alive"....that's why I've asked if the issue has been solved...

-

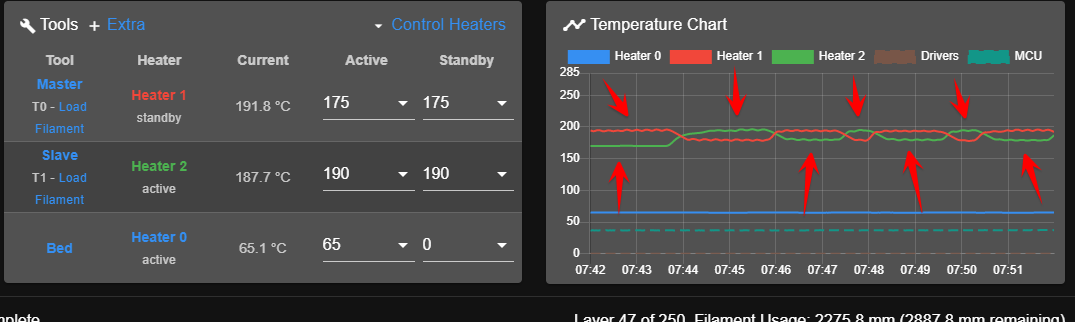

I have the same problem. From 3.4-b7 to 3.4-rc2_1 I have the temperature issue. This goes up about 10° and down again. But the funny thing is only at Z=2.1mm. With 3.4-b5 this is ok. I did everything PID. It's not on the slicer either, I've tested different ones.

On 3.4-b7 the temperature is constant up to Z=2.1mm and then it starts.

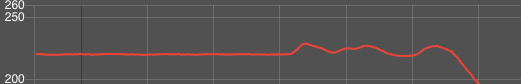

and this is on 3.4-b5 the temperature is constant throughout the printing

-

@TheDragonLord Sorry, I see from your first post that you are using the new M307 parameters. Though according to @dc42 even if you used the old parameters, the values are converted to the new parameters.

When you tuned the heaters, did you tune them with the nozzles close to the bed, ie within 1mm?

The fluctuation looks much more like it’s not dealing with the cooling fan being on, or somehow on tool change the heater tuning for the cooling fan being on is inverted, so it thinks the fan is on when it’s not, and vice versa.

Please post your tool change files, so we can see what is happening there.

Ian

-

@thedragonlord PID Tune your heater (H) instead of your tool (T). If you PID tune your heater it will not tune with the fan, therefore it will not (over)compensate it.

You can also remove the values for fan compensation in your present PID values.

-

@hernicz said in Temperatures totally wrong 3.4 RC:

@thedragonlord PID Tune your heater (H) instead of your tool (T). If you PID tune your heater it will not tune with the fan, therefore it will not (over)compensate it.

You can also remove the values for fan compensation in your present PID values.

I'll give it a try, thanks

-

@hernicz said in Temperatures totally wrong 3.4 RC:

@thedragonlord PID Tune your heater (H) instead of your tool (T). If you PID tune your heater it will not tune with the fan, therefore it will not (over)compensate it.

You can also remove the values for fan compensation in your present PID values.

It works thanks!

-

@thedragonlord You're welcome.