Hi in another thread (https://forum.duet3d.com/topic/25931/input-shaping-testing-and-thoughts) I reported my progress with using input shaping to deal with some of the ringing on my printer. As a result of these tests I decided to take a closer look at how klipper and RRF collect resonance data to be used as the basis for analysis of ringing and to help a user configure input shaping. Hopefully this will provide some useful input to @DC42 and @mfs12 in the production of the RRF input shaper plugin.

So both systems basically run some sort of movement to excite resonances in the printer and use an accelerometer to collect the data, In particular:

- RRF performs a simple linear move at the maximum current movement speed and when that move stops it then collects typically 1000 samples (taking less than a second) which is about 46kBytes of data.

- klipper runs what they call a resonance test that basically moves the print head from side to side a short distance ramping up the speed (and acceleration) of these movements to scan through a set of frequencies (the default range is 5 to 133Hz). This generates about 130 seconds worth of data, which is typically 170,000 samples, 3.6MBytes of data.

To allow comparison of the two I created a script that generates a klipper style set of movements to allow me to record a set of sample use RRF.

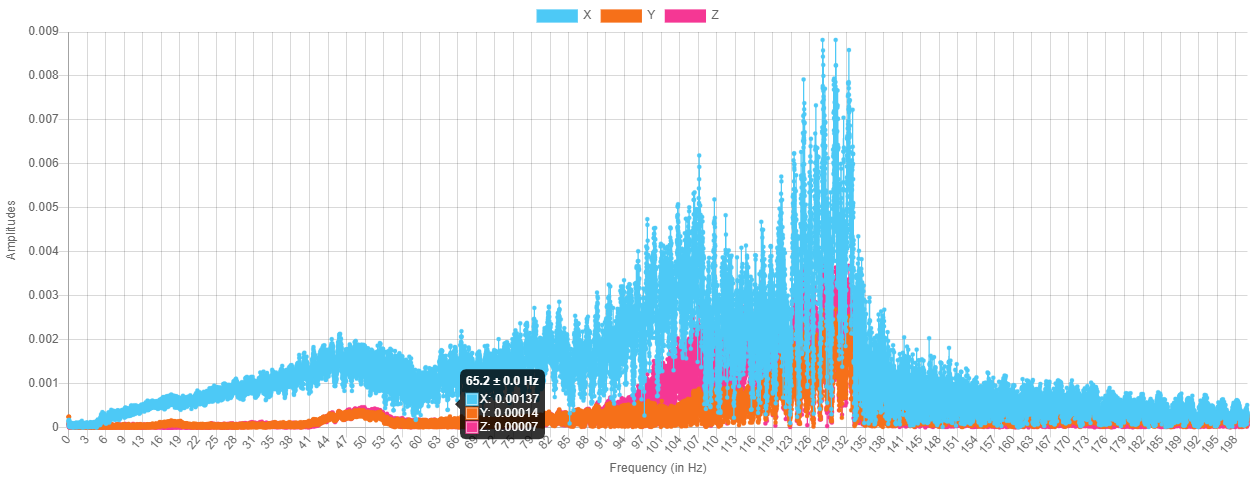

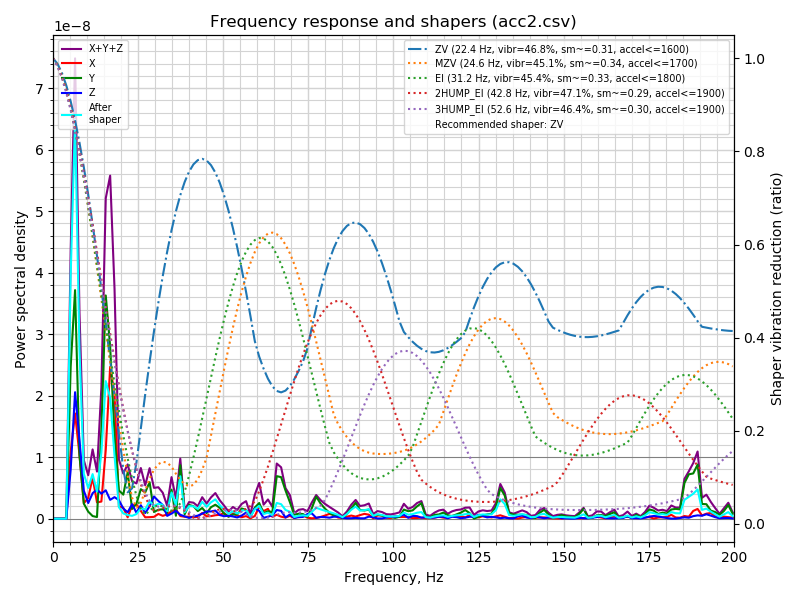

I collected two sets of data on my CoreXY printer. The first graph shows the RRF FFT results:

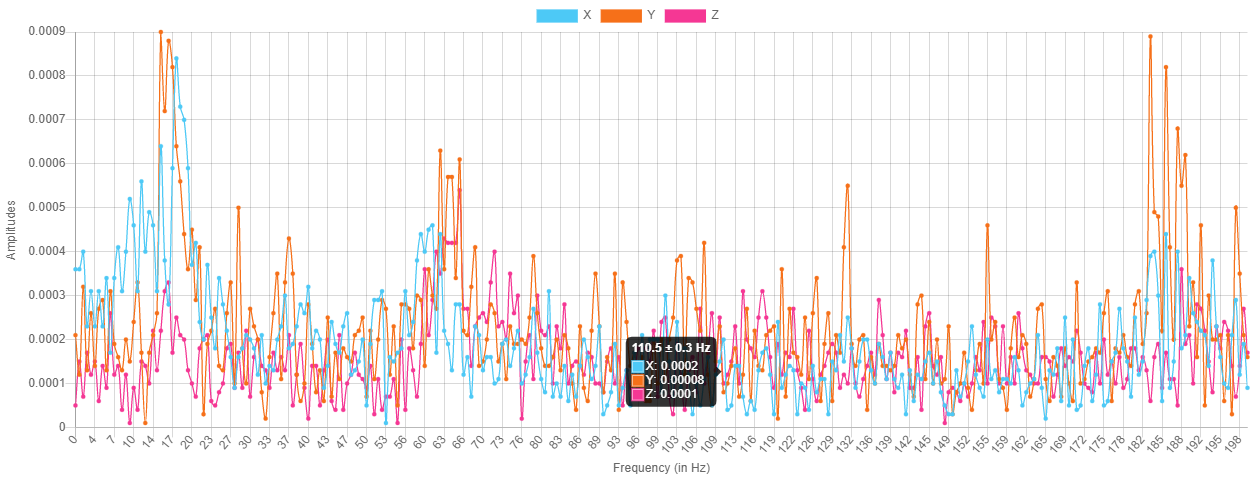

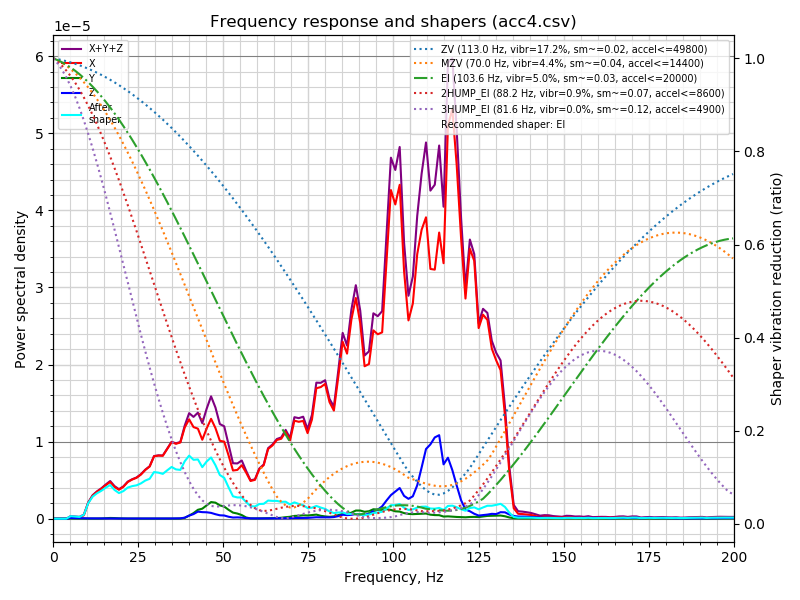

The second is the klipper style data:

As can be seen the give very different results!

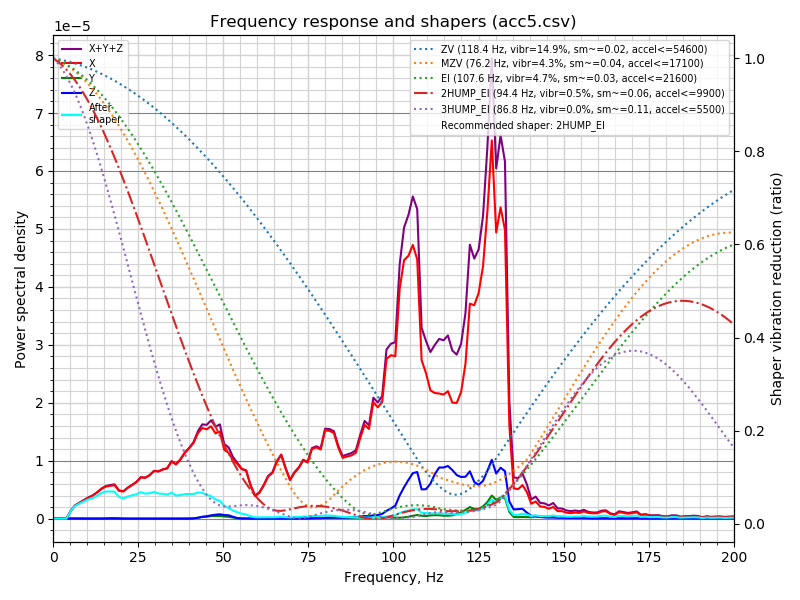

I also modified the sample files to allow them to be processed by the klipper calibrate_shaper.py script. For the RRF style data it gave:

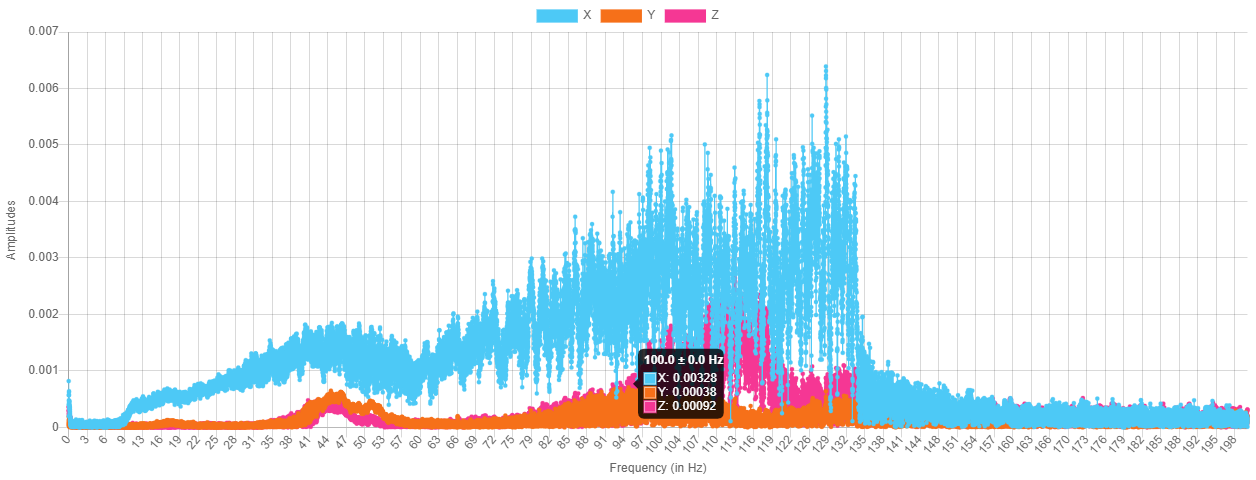

The klipper style data gives:

With such different outcomes it is hard to really decide which is correct. I've not tested the recommendation based on the klipper style data (RRF does not currently support the ei shaper). However based on my previous tests (and on measuring the ringing on the prints), the main visible problem is the hump that can be seen around 40Hz on the klipper style data. Some further thoughts and comments....

- Looking at the raw samples the current RRF data set only has a very small number of actual "real" values, in the file shown here only the first 100 points are above the noise floor. I'm not sure if this is really enough data to allow for an accurate analysis of what is happening over the given frequency range.

- The current input shaper plugin performs the test using the maximum movement speed, in my case this was 200mm/s. I'm not sure that this is a good idea. On my machine this introduces a considerable amount of energy into the frame of the printer such that it rocks. I'm pretty sure that this is responsible for the very low frequency peaks shown in the output. Reducing the maximum speed gives a different output (with not such a large low frequency peak), but has even fewer samples above the noise.

- To check that the "klipper" data was working correctly I monitored the test using a "spectrum analyser" app on my phone and it did indeed show a rising frequency from around 5Hz to 133Hz. So I think it is working correctly.

- To allow me to collect the larger volume of data needed for the klipper runs I had to modify RRF (in this case the STM32 port) to allow more than 64K of samples and also to fix an overflow problem in the data rate calculation when there are a large number of samples being saved.

I will continue to investigate this a little further, but I thought this data might be of interest and I'd welcome any thoughts or feedback.