Heater Code setup question

-

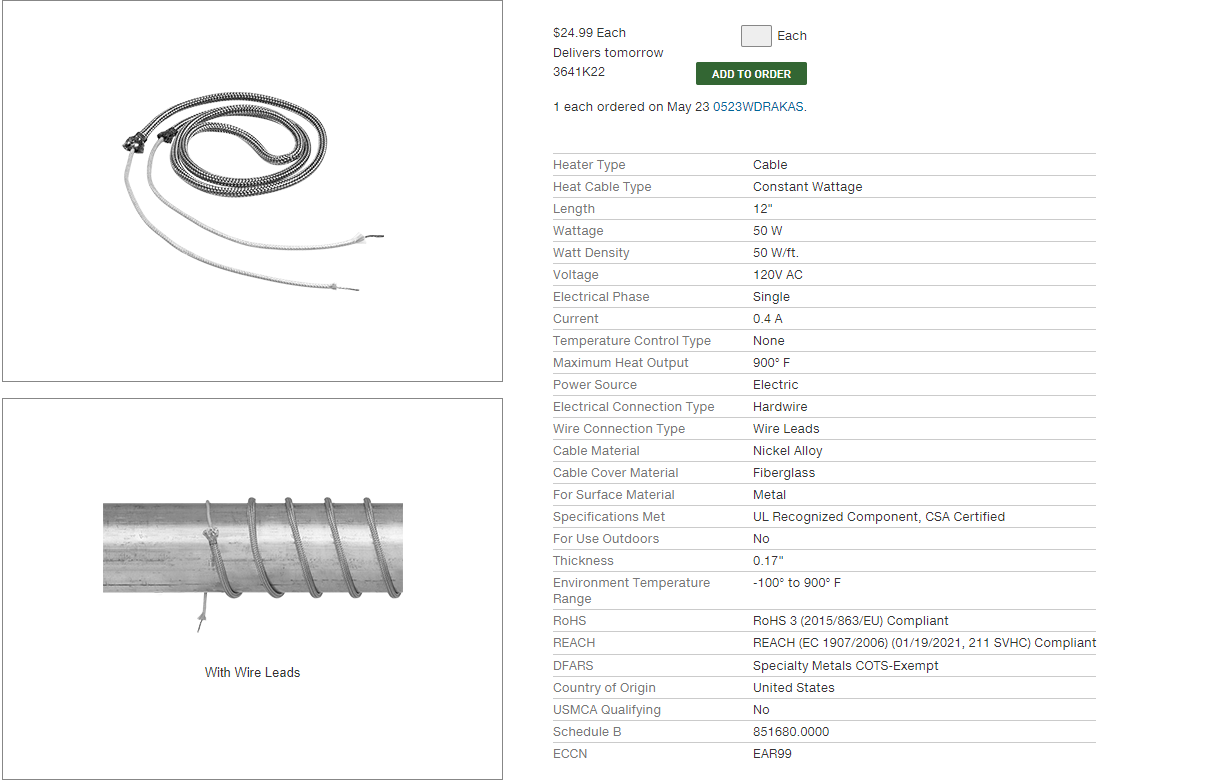

I am trying to use this heating element,

I am utilizing a solid state relay and i belive it is wired correctly.

my question is: does my config for the heater look correct. I have two temp. sensors on the device. so ideally i'd like two temp sensors for one tool.The issue is when i set it active and to 215 degrees, it doesnt heat up and produces a heater fault for heating at less than 0.7 Celsius per second.

Here is my config:

;M575 P1 B57600 S1 ; Drives M584 X0 Y1 Z2:5 E4 ; set drive mapping M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S0 ; physical drive 1 goes forwards M569 P2 S0 M569 P4 S0 ; physical drive 2 goes FORwards M569 P3 S0 ; physical drive 3 goes forwards M569 P5 S1 ; physical drive 3 goes forwards ;M569 P7 S0 ; physical drive 3 goes forwards ;M569 P8 S0 ; physical drive 3 goes forwards M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z2000.00 E100.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X200 Y200 Z200 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 P"zstop" ; configure Z-probe endstop for low end on Z ; Z-Probe ; new probe bl touch ;M558 P9 C"^zprobe.in" H5 F100 T2000 ;M950 S0 C"duex.pwm1" ;G31 X20 Y0 Z9 P25 ;M557 X15:762 Y15:762 S20 ; define mesh grid ; Heaters M140 H-1 ; disable heated bed (overrides default heater mapping) M308 S0 P"e0temp" Y"thermistor" T100000 B4138 F10 ; configure sensor 0 as thermistor on pin e0temp M950 H0 C"e0heat" T0 Q10 ; create nozzle heater output on e0heat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H0 S260 ; set temperature limit for heater 0 to 260C M570 P180 ; 180 seconds till heater fault M308 S3 A"Chamber" P"e1_temp" Y"thermistor" T100000 B3950 ; second thermister ; Fans ; Tools M563 P0 D0 H0 S"Main" ; define tool 1 G10 P0 X0 Y0 Z0 ; set tool 1 axis offsets G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@drak said in Heater Code setup question:

M308 S0 P"e0temp" Y"thermistor" T100000 B4138 F10 ; configure sensor 0 as thermistor on pin e0temp

M950 H0 C"e0heat" T0 Q10 ; create nozzle heater output on e0heat and map it to sensor 0

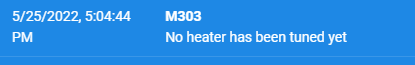

M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limitI assume it is heater 0. The M308 and M950 commands look reasonable, however you haven't tuned the heater. You probably need to run M303 heater tuning before you can get it working.

More things to check:

- Does the temperature reading appear to be correct?

- If the SSR has an LED to indicate when it is turned on, does that LED light initially (before the fault is reported) when you command the heater to heat up?

-

@dc42

The temp seems reasonable when the hot end it inactive. It reads 25 degrees celcius which is around room temp.The light on the ssr does light up when i set it active to 215 temp.

When i run the 303 command i get this error:

-

@drak you need to provide H and S parameters in the M303 command.

-

@dc42

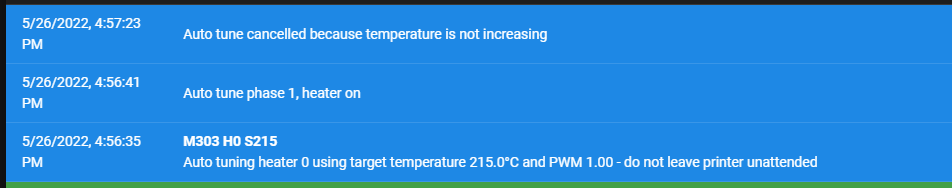

the tuning seemed to cancel itself, here is the console:

-

Is the heater actually getting warmer? Did the temp graph register an increase in temp?

-

@phaedrux

The temp. would increase but only by 2-3 degrees total before the tuning stopped. -

@dc42

how would i confirm the SSR is wired correctly?

The red light does come on when i set the tool active to 215 -

How is the thermistor attached to the bed? It seems like they are very weakly physically coupled.

-

@phaedrux

is heater 0 only meant for the bed, because the heater element im using is meant for a hot end -

No, heater 0 is just the first heater. It can be used for a hotend.

You may want to try bang-bang mode with this heater.

But where is the thermistor in relation to the rest of the heater? Can you show us photos of the setup?

-

@phaedrux

how would i activate bang bang mode?

here is picture:

i have both close to heating element. originally i had them directly on aluminum but i moved them closer since they werent reading any changes in temp

-

That's a very loose connection between the theristor and the heat source.

You've got two thermistors in there, which are you trying to use for control?

-

@phaedrux should i directly tape them to the heating element?

-

@phaedrux

how do i activate bang bang mode? -

@drak said in Heater Code setup question:

M307 H0 B0 S1.00

M307 H0 B1 S1.00

B1 would be bang bang mode. But it's still going to have to register a temp increase for it to not fault out.

Is this a temporary setup, or intended for actual use?

-

@phaedrux the goal is to use this heating element long term

-

In this configuration, or improved? At the moment, it's a bit "janky" as the kids say.

I wouldn't want to run a heater control with a thermistor attached with tape. When it falls off (and it will) at best you ruin a print.

-

@phaedrux this setup is just to workout the duet control side of the heating element and make sure i can heat up the aluminum consistantly

-

the goal is to use this heating element long term

What temperatures do you aim at with this bold construction? From what I can see on your photo, most of the 50 watts dissipate into air, the rest tries to heat up the aluminum, the clamps and all the other metal connected by those.

Sure you can control that with the Duet - the question is: Can such a construct be covered by the PID tuning, or is the heat increase too slow for the algorithm? In the latter case, you will want to insert proper values for

M307by guess. Here you can look up the details. -

undefined Drak referenced this topic

undefined Drak referenced this topic