1HCL position failure home position G-code

-

Hello, where do I find the correct g-code example to tell my 1HCL boards to move my printer to home position on failure to maintain position fault. At one point this featured worked and I think after an update a while back it stopped. Currently my printer experiences the fault and it simply stops at the end of a command line and rests at that position awaiting the resume command.

-

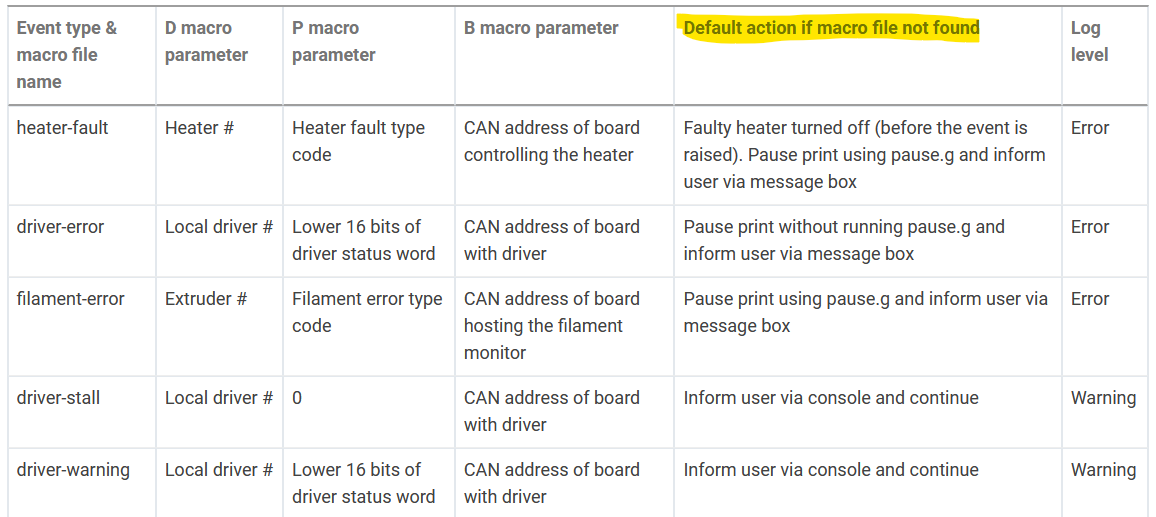

@supertb1 assuming you are running RRF 3.4.x you need to create an event handler macro in /sys. See https://docs.duet3d.com/en/User_manual/RepRapFirmware/Events to get started.

-

@dc42 Awesome, yes, it is up to date. Thank you

-

@dc42 So I am sorry for being a little naive about this but it looks like someplace in the sys. folder or a macro I need to set up an M505 D (canbus 50-51) ; Pause print using pause.g and inform user via message box... I am not sure I understand where to put this line of code or how exactly it is supposed to look. I have 1HCLs on both my X,Y drives. What would an example of this code look like? or if it exists where do I find it to change the behavior?.. again I am sorry for not understanding this.

-

@supertb1

You need to create a macro for each of the events you want to handle.

The names are in the left-most column here from the link DC42 gave you.So for example you need

driver-stall.g to be located in your /sys directory and within that put whatever action you want to take on a driver stall.

Note that it takes some tuning of your M915 settings to get stall detection working well.This is my driver-stall.g

There's probably bunch of superfluous code in it that I was using to understand what was going on when it was called. I'm also undecided whether the M400 is a good idea or not.;0:/sys/driver-stall.g echo " A driver stall has occured on driver " ^ param.D echo "Layer shifting may have occured at X:",move.axes[0].machinePosition, "Y:", move.axes[1].machinePosition, "Z:", move.axes[2].machinePosition echo "Requested speed is " , move.currentMove.requestedSpeed, "mm/sec. Top speed is", move.currentMove.topSpeed, "mm/sec" ; check if a driver stall is already being acted on by looking at global variable we created in config.g. if global.InMacro=true echo "Driver stall macro already running - no further action taken" M99 ; exit macro M400 ; finish current moves if job.file.fileName!= null ; check if we are printing set global.InMacro=true ; stop the macro being run multiple times G60 S3 ; save position to slot 3 echo "File position is ", job.filePosition, "bytes" echo "Physical position is X:",move.axes[0].machinePosition, "Y:", move.axes[1].machinePosition, "Z:", move.axes[2].machinePosition G4 P5 ; if a tool is selected and the heater is up to temp we'll retract if heat.heaters[tools[max(state.currentTool,0)].heaters[0]].current > heat.coldRetractTemperature G10 G1 F1800 ; reduce speed before homing G28 X Y ; home X & Y G1 F1200 ; reduce speed when travelling back to saved slot G1 R3 X0 Y0 Z5; travel to 5mm above stall position M400 G1 F60 ; reduce speed G1 R3 X0 Y0 Z0 ; move to stall position M400 ; if a tool is selected and the heater is up to temp, we'll un-retract if required. if (heat.heaters[tools[max(state.currentTool,0)].heaters[0]].current > heat.coldExtrudeTemperature) && (tools[max(state.currentTool,0)].isRetracted) G11 set global.InMacro = false ; unset the flagYou would create the other macros and code them to suit your needs.

- driver-error.g

- driver-warning.g

- heater-fault.g

- filament-error.g

-

@OwenD Thanks for the example, so by this to me looks like you are operating in open loop and your command ("X:",move.axes[0].machinePosition, "Y:", move.axes[1].machinePosition, "Z:", move.axes[2]) is calling the physical address on your main board for your steppers, Correct? so for me it would be "X:",move.axiz[50].machinePosition, "Y:", move.axes[51].machinePosition, "Z:", move.axes[2]).....

Does that look correct @dc42 & @OwenD ? or am I good to just plug this in and run with it? -

@supertb1

move.axes[n] is an object model array.

There will be one array item for each configured axis.

move.axes[0].machinePosition simply reports the position of the X axis.

Likewise the others report the position of the Y & Z axis at the time the macro was run.

So unless you have 52 axes, then your example would give an error.Perhaps start with something like

;driver-stall.g G60 S3 ; save position to slot 3 G28 X Y ; home X & Y G1 R3 X0 Y0 Z0 ; Move back to saved positionYou can test it by sending M957 to simulate a fault (or deliberately cause a stall by hand)

M957 E"driver-stall" D1 -

@OwenD P50-P51 are my 1HCL CANBUS drive addresses.. the question was weather or not I needed to put that information in place of the mainboard driver addresses or if the line codes as you have them listed would work as they are... see what I am looking for is someone who knows the code architecture well enough on MB6HC that I can create whatever directory needed in the .sys and then dump the example in there with the correct format to keep my system from crashing... what can I give you or @dc42 that can help me with that... as I have stated before I am a noob when it comes to this issue... I have no formal education on this system, everything has been trial and error..lol... I just want my system to return to the home position when it runs into a position failure like it did 5 or 6 updates ago

-

@supertb1

You have been provided multiple links to the relevant documentation and have been given examples of possible code and how to test it.

Until you read the documentation and apply the examples then I can't help any further as I don't have an identical system. -

@OwenD Ok, thank you for your help on this.. I will give it a shot and get back to you.

-

@OwenD Hello, I made a file (driver-stall.g) in my .sys directory and dropped the example in there. then I entered M957 E"driver-stall" D1 in my command line and it returned "M957 E"driver-stall" D1

Warning: Driver 0.1". now it does not recognize my tool, it immediately causes my X axis to fail to maintain position. so the settings in the stall file need to be adjusted. Ok I have a Duet 3 6HC, "2" 1HCL boards (P50,P51) X and Y respectively. "2" Z axis motors (0,1) on the main board. The extruder is on (4). do I need to place the physical address of the drives that are on the boards inside the [0] on the command lines for this driver stall.g and how would the Z axis look on the command line? move.axes[0,1]? I tried to enter the actual board addresses in the command lines and it still does not recognize the tool. ok.. so I don't think your model as it is will work for my setup. I tried your ";driver-stall.gG60 S3 ; save position to slot 3G28 X Y ; home X & YG1 R3 X0 Y0 Z0 ; Move back to saved position" line and it causes my machine to forget the X and Z axis home at the start of my print end the program and then home the X and Z axis so that is not going to work either. What changes need to be made to these examples to help make them work for my applications? what information can I give to you to help with this process? -

@dc42 you know what would make this all alot easier is if I could simply change the default process from "Pause print without running pause.g and inform user via message box" to "Pause print using pause.g and inform user via message box" How do I do that? Or better yet, can I get a firmware update that has that change in it?

-

@supertb1

I cannot work out exactly what you are doing by your answers.

You appear to be mixing all sorts of things together.You need to read and understand the documentation given to you so that you can grasp the way the firmware works.

There are two possible work flows with any of the events.

One will happen if you have not created a macro to handle the event and the other will happen if you have created a macro to handle it

So in the case of a DRIVER ERROR, then if there is no file in the/sys directory called driver-error.g, then the firmware will pause the print without running pause.g and a message box will appear. It will just stop.

If there IS a file called driver-error.g in the /sys directory, then you determine what happens by the contents of your macro.The parameters mentioned are NOT parameters that you send.

They are parameters that you can access within your macro so that you can have one macro but take different actions depending where the fault was.

So for example in my driver-error.g macro I could putecho "Fault on driver" ^ param.Dand it would report which driver number the error happened on.

You are going to need to post the following files.

config.g

driver-error.g

driver-stall.g

homeall.g

homex.g

homey.g

pause.gWhen you post them, please ensure that you use the </> button so the contents appear is a code box like this

code boxThis will make them readable.

Also post the firmware version you are using on all attached boards, by sending

M115 B0

M115 B1

M115 B2

one command at a time from the console.After all that we will need to know exactly what problem(s) you are trying to fix?

There is no point for example focusing on a driver-stall.g file, if your problem is actually a driver error, and not a stall. -

code_text ```; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Colossus Openbuild" ; set printer name ; Network M552 P192.168.1.65 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives G4 S1 ;wait for expansion boards to start M569.1 P50.0 T2 C5 E5:10 ; Configure the 1HCL board at CAN address 50 with a quadrature encoder on the motor shaft that has 20 steps per motor full step. M569.1 P51.0 T2 C5 E5:10 ; Configure the 1HCL board at CAN address 51 with a quadrature encoder on the motor shaft that has 20 steps per motor full step. M569 P50.0 D4 S1 ; Configure the motor on the 1HCL at can address 50 as being in closed-loop drive mode (D4), Open loop (D2) and not reversed (S1) X axis M569 P51.0 D4 S1 ; Configure the motor on the 1HCL at can address 51 as being in closed-loop drive mode (D4), Open loop (D2) and not reversed (S1) Y axis M569 P0.0 S1 ; physical drive 0.0 goes forwards Z 1-2 axis M569 P0.4 S1 ; physical drive 0.4 goes forwards Extruder M584 X50.0 Y51.0 Z0.0:0.1 E0.4 ; set drive mapping M671 X-122.25:689.20 Y0:0 S3.0 ; leadscrews at left (connected to Z0) and right (connected to Z1) of X axis M350 X32 Y32 Z32 E16 I1 ; configure microstepping with interpolation M92 X106.5 Y257 Z795.00 E339.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1000 Y3000 Z3000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M917 X10 Y0 ; Set the closed loop axes to have a holding current of zero ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X609 Y609 Z762 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!^io1.in" ; configure active-high endstop for low end on X via pin !^io1.in M574 Y1 S1 P"!^io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z M591 D0 P7 C"io5.in" L7 R55:150 E22 S1 ;Bigtree smart filament moniter v2 set to moniter between 55%-150% of 7 counts over a distance of 22mm M591 D0 ; display filament sensor parameters for extruder drive 4 M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"^io7.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P100 X60 Y0 Z2.68 ; set Z probe trigger value, offset and trigger height M557 X100:500 Y100:500 S100 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B1 S10.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out2" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 C"Tool Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out6" Q500 ; create fan 1 on pin out6 and set its frequency M950 F2 C"out7" Q500 ; create fan 2 on pin out7 and set its frequency M106 P1 C"Extruder" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on ; Tools M563 P0 S"Hemera" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue </>drive-error.g ; pause.g ; called when a print from SD card is paused ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M83 ; relative extruder moves G1 E-10 F3600 ; retract 10mm of filament G91 ; relative positioning G1 Z5 F360 ; lift Z by 5mm G90 ; absolute positioning G1 X0 Y0 F6000 ; go to X=0 Y=0 </>driver-stall.g ; pause.g ; called when a print from SD card is paused ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M83 ; relative extruder moves G1 E-10 F3600 ; retract 10mm of filament G91 ; relative positioning G1 Z5 F360 ; lift Z by 5mm G90 ; absolute positioning G1 X0 Y0 F6000 ; go to X=0 Y=0 </>homeall.g (wich I do not use because it doesn't work) ; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-605 Y-605 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-605 Y-605 F360 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X10 Y10 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning </>; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) M569 P50.0 D0 ; Turn off closed loop G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F6000 ; go back a few mm G1 H1 X-240 F240 ; move slowly to X axis endstop once more (second pass) G90 ; absolute positioning G1 X50 F3000 ; Move to a known-safe position M400 ; Wait for the move to complete G4 P500 ; Wait for the motor to settle M569 P50.0 D4 ; Turn closed loop back on M569.6 P50.0 V31 ; Perform the tuning manoeuvres for a quadrature encoder G1 X0 ; Move back to X0 G1 H2 Z0 F6000 ; lower Z again </>Home Y ; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M569 P51.0 D0 ; Turn off closed loop G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y-240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 Y5 F6000 ; go back a few mm G1 H1 Y-240 F240 ; move slowly to X axis endstop once more (second pass) G90 ; absolute positioning G1 Y25 F3000 ; Move to a known-safe position M400 ; Wait for the move to complete G4 P500 ; Wait for the motor to settle M569 P51.0 D4 ; Turn closed loop back on M569.6 P51.0 V31 ; Perform the tuning manoeuvres for a quadrature encoder G1 Y0 ; Move back to X0 G1 H2 Z0 F6000 ; lower Z again </> pause.g ; pause.g ; called when a print from SD card is paused ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M83 ; relative extruder moves G1 E-10 F3600 ; retract 10mm of filament G91 ; relative positioning G1 Z5 F360 ; lift Z by 5mm G90 ; absolute positioning G1 X0 Y0 F6000 ; go to X=0 Y=0 / </>11/6/2022, 7:38:44 PM M115 B0 FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.4.4 ELECTRONICS: Duet 3 MB6HC v1.01 FIRMWARE_DATE: 2022-10-20 16:19:01 / </>11/6/2022, 7:39:24 PM M115 B1 Error: M115: Response timeout: CAN addr 1, req type 6024, RID=14 / </>11/6/2022, 7:40:03 PM M115 B2 Error: M115: Response timeout: CAN addr 2, req type 6024, RID=15 / Issue at hand: when my printer fails to maintain position or the X-Y steppers stalls I want it to move my print head to home position Z+5 like it used to do. -

@supertb1

I meant for you to put each file in its own code block so we could know exactly what you are working with.

I will try to separate and comment as I can.Config.g

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Colossus Openbuild" ; set printer name ; Network M552 P192.168.1.65 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives G4 S1 ;wait for expansion boards to start M569.1 P50.0 T2 C5 E5:10 ; Configure the 1HCL board at CAN address 50 with a quadrature encoder on the motor shaft that has 20 steps per motor full step. M569.1 P51.0 T2 C5 E5:10 ; Configure the 1HCL board at CAN address 51 with a quadrature encoder on the motor shaft that has 20 steps per motor full step. M569 P50.0 D4 S1 ; Configure the motor on the 1HCL at can address 50 as being in closed-loop drive mode (D4), Open loop (D2) and not reversed (S1) X axis M569 P51.0 D4 S1 ; Configure the motor on the 1HCL at can address 51 as being in closed-loop drive mode (D4), Open loop (D2) and not reversed (S1) Y axis M569 P0.0 S1 ; physical drive 0.0 goes forwards Z 1-2 axis M569 P0.4 S1 ; physical drive 0.4 goes forwards Extruder M584 X50.0 Y51.0 Z0.0:0.1 E0.4 ; set drive mapping M671 X-122.25:689.20 Y0:0 S3.0 ; leadscrews at left (connected to Z0) and right (connected to Z1) of X axis M350 X32 Y32 Z32 E16 I1 ; configure microstepping with interpolation M92 X106.5 Y257 Z795.00 E339.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1000 Y3000 Z3000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M917 X10 Y0 ; Set the closed loop axes to have a holding current of zero ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X609 Y609 Z762 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!^io1.in" ; configure active-high endstop for low end on X via pin !^io1.in M574 Y1 S1 P"!^io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z M591 D0 P7 C"io5.in" L7 R55:150 E22 S1 ;Bigtree smart filament moniter v2 set to moniter between 55%-150% of 7 counts over a distance of 22mm M591 D0 ; display filament sensor parameters for extruder drive 4 M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"^io7.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P100 X60 Y0 Z2.68 ; set Z probe trigger value, offset and trigger height M557 X100:500 Y100:500 S100 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B1 S10.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out2" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 C"Tool Fan" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out6" Q500 ; create fan 1 on pin out6 and set its frequency M950 F2 C"out7" Q500 ; create fan 2 on pin out7 and set its frequency M106 P1 C"Extruder" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on ; Tools M563 P0 S"Hemera" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue</>drive-error.g

Is this a typo?

The file should be driver-error.g; pause.g ; called when a print from SD card is paused ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M83 ; relative extruder moves G1 E-10 F3600 ; retract 10mm of filament G91 ; relative positioning G1 Z5 F360 ; lift Z by 5mm G90 ; absolute positioning G1 X0 Y0 F6000 ; go to X=0 Y=0This would try to go to X0 Y0 for any driver error, but if a driver is in error state, that may not be possible.

driver-stall.g

; pause.g ; called when a print from SD card is paused ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M83 ; relative extruder moves G1 E-10 F3600 ; retract 10mm of filament G91 ; relative positioning G1 Z5 F360 ; lift Z by 5mm G90 ; absolute positioning G1 X0 Y0 F6000 ; go to X=0 Y=0Again, you are trying to go to X0 Y0

What happens when you force a driver to stall?

Does the machine move to X0 Y0?

Note, that you have not re-homed the axis, so it may move to where it "thinks" X0 Y0 is, but if it had already skipped many steps then it may end up somewhere entirely different.

EDIT: I don't know exactly how running closed loop will fit into this. It's possible the motor can stall and not lose track of position. That's the whole idea I guess.</>homeall.g (wich I do not use because it doesn't work)

What doesn't work?

What happens when you issue G28?

I note you have no M569.1 commands in this file, but yo do in homex.g and homey.g; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-605 Y-605 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-605 Y-605 F360 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X10 Y10 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioning</>; homex.g

; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) M569 P50.0 D0 ; Turn off closed loop G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F6000 ; go back a few mm G1 H1 X-240 F240 ; move slowly to X axis endstop once more (second pass) G90 ; absolute positioning G1 X50 F3000 ; Move to a known-safe position M400 ; Wait for the move to complete G4 P500 ; Wait for the motor to settle M569 P50.0 D4 ; Turn closed loop back on M569.6 P50.0 V31 ; Perform the tuning manoeuvres for a quadrature encoder G1 X0 ; Move back to X0 G1 H2 Z0 F6000 ; lower Z again</>Home Y

; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M569 P51.0 D0 ; Turn off closed loop G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y-240 F3000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 Y5 F6000 ; go back a few mm G1 H1 Y-240 F240 ; move slowly to X axis endstop once more (second pass) G90 ; absolute positioning G1 Y25 F3000 ; Move to a known-safe position M400 ; Wait for the move to complete G4 P500 ; Wait for the motor to settle M569 P51.0 D4 ; Turn closed loop back on M569.6 P51.0 V31 ; Perform the tuning manoeuvres for a quadrature encoder G1 Y0 ; Move back to X0 G1 H2 Z0 F6000 ; lower Z again</> pause.g

; pause.g ; called when a print from SD card is paused ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:32 GMT-0600 (Central Standard Time) M83 ; relative extruder moves G1 E-10 F3600 ; retract 10mm of filament G91 ; relative positioning G1 Z5 F360 ; lift Z by 5mm G90 ; absolute positioning G1 X0 Y0 F6000 ; go to X=0 Y=0</>11/6/2022, 7:38:44 PM M115 B0

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.4.4 ELECTRONICS: Duet 3 MB6HC v1.01 FIRMWARE_DATE: 2022-10-20 16:19:01</>11/6/2022, 7:39:24 PM M115 B1

Error: M115: Response timeout: CAN addr 1, req type 6024, RID=14

/

</>11/6/2022, 7:40:03 PM M115 B2

Error: M115: Response timeout: CAN addr 2, req type 6024, RID=15I don't know enough about the 1HCL boards to interpret these errors.

Issue at hand: when my printer fails to maintain position or the X-Y steppers stalls I want it to move my print head to home position Z+5 like it used to do.

Again, what does it do now when there is a stall.

"Like it used to"?

When did it do that?

What has changed since then? e.g. Firmware? From what version to what version? -

@supertb1

In addition to above, I suggest you put the following lines at the start of your diver-error.g and driver-stall.g files.

This will help identify which is being called and what the fault is.

This is because the macro called will be dependent on whether the loss of position is greater than or less than the E parameter in your M569.1 for that axis.;driver-stall.g echo "Driver stall has occurred" echo param.S ; send error message to console;driver-error.g echo "Driver error has occurred" echo param.S ; send error message to consoleEDIT.

Also the code for the firmware on the expansion boards should be

M115 B50

M115 B51

You have to send the CAN address for these boards. -

@OwenD

"</>drive-error.g

Is this a typo?

The file should be driver-error.g"

no this was me learning to use this sites text box."This would try to go to X0 Y0 for any driver error, but if a driver is in error state, that may not be possible.

driver-stall.g"

in closed loop the machine knows where it is at all times. however if the motor failed or the drive board "1HC" failed I am sure the system wouldn't function as intended, I have not had this issue yet.

"Again, you are trying to go to X0 Y0

What happens when you force a driver to stall?

Does the machine move to X0 Y0?

Note, that you have not re-homed the axis, so it may move to where it "thinks" X0 Y0 is, but if it had already skipped many steps then it may end up somewhere entirely different.

EDIT: I don't know exactly how running closed loop will fit into this. It's possible the motor can stall and not lose track of position. That's the whole idea I guess."

Correct."</>homeall.g (wich I do not use because it doesn't work)

What doesn't work?

What happens when you issue G28?

I note you have no M569.1 commands in this file, but yo do in homex.g and homey.g; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Mar 08 2021 08:53:31 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-605 Y-605 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-605 Y-605 F360 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X10 Y10 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F100 ; lift Z relative to current position ;G90 ; absolute positioningIt causes the machine to wait for a count of 2 minutes and then it homes the X axis, then the Z axis, then the X axis again, and then the Z axis again. this feature has never worked correctly while the 1HC boards have been in use. It worked fine when I had the axis drivers on the main board.

"Again, what does it do now when there is a stall.

"Like it used to"?

When did it do that?

What has changed since then? e.g. Firmware? From what version to what version?"

Before 3.0 the system would send the axis back to home on a "failure to maintain position" I believe. it is only been in the last year that I have began to have this problem.11/7/2022, 8:51:38 AM M115 B50 Duet EXP1HCL firmware version 3.4.4 (2022-10-14 11:45:14) 11/7/2022, 8:52:07 AM M115 B51 Duet EXP1HCL firmware version 3.4.4 (2022-10-14 11:45:14)with the stall and error.g files as they are, a manual move from position generates a "Error: attempting to extrude with no tool selected." fault on the PanelDue 7.

Running a simple bed leveling program and causing a stall causes the print head to move toward home but then it raises the print head 5mm and then it goes back out to print... so wierd.11/7/2022, 9:04:07 AM Resume state saved 11/7/2022, 9:03:46 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 9:03:29 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 9:02:54 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 9:00:02 AM Error: Attempting to extrude with no tool selected. 11/7/2022, 8:57:24 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 8:54:27 AM Driver error has occurred Driver 50.0 error: failed to maintain position Error: Attempting to extrude with no tool selected. 11/7/2022, 8:54:06 AM Error: Attempting to extrude with no tool selected. 11/7/2022, 8:53:58 AM Driver error has occurred Driver 51.0 error: failed to maintain positionso the drive-error.g and the driver-stall.g will not work as they are currently. But we are getting somewhere, at least it isn't just stopping in the middle of the print anymore.

-

@supertb1 said in 1HCL position failure home position G-code:

with the stall and error.g files as they are, a manual move from position generates a "Error: attempting to extrude with no tool selected." fault on the PanelDue 7.

Are you saying an attempt to move X and Y by say G1 X100 Y100 returns that error?

Running a simple bed leveling program and causing a stall causes the print head to move toward home but then it raises the print head 5mm and then it goes back out to print... so wierd.

11/7/2022, 9:04:07 AM Resume state saved 11/7/2022, 9:03:46 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 9:03:29 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 9:02:54 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 9:00:02 AM Error: Attempting to extrude with no tool selected. 11/7/2022, 8:57:24 AM Driver error has occurred Driver 50.0 error: failed to maintain position 11/7/2022, 8:54:27 AM Driver error has occurred Driver 50.0 error: failed to maintain position Error: Attempting to extrude with no tool selected. so the drive-error.g and the driver-stall.g will not work as they are currently. But we are getting somewhere, at least it isn't just stopping in the middle of the print anymore.So when you run the bed levelling, did you first select a tool and get the extruder up to temp?

In your stall.g and error.g you have simply copied your pause.gThis will make it

move to X0 Y0

raise Z

Retract 10mm

Then return to print jobYou can't retract (extrude) without a tool selected!

So it sounds like it's doing what you told it to do.

You must either re-home it to ensure that the position is now correct or pause it if that's what you want.

Any retraction etc should first have a check that a tool is selected and up to temp.I'll have to leave any behaviour differences in firmware to @DC42

-

@OwenD

No what I am saying is that while the system is running a program a manual move from intended path returns the ""Error: attempting to extrude with no tool selected." fault on the PanelDue 7." and then the aforementioned behavior ensues. And no I usually do not preheat the tool, that is in the gcode of the slicer app and yes the overall behaviour of any kind of motor stall of the X-Y axis needs to be "Go to the pause location" IE home Z+5. That is the ultamate goal -

@supertb1

I don't know if there is a language barrier, or if you're being deliberately obtuse.

If you want it to go to X0 Y0 Z+5, then wait, you must tell it that and only that!

I'm afraid I have nothing more to offer you.