PT100 board issue (wiring probably)

-

Hi all

I'm having an issue with the PT100 Board – it results in a 2000° C reading. As indicated, this is probably a short somewhere, but i don't see where. As I don't want to fry my boards, I prefer to ask for help:- Board is ok on both inputs

- Connections are ok (2 wire and suggested 4-wire-mod tested)

- Config is also ok (by the 100 ohm test)

- Heatbed (with Keenovo heatpad glued on) is on ground

When I check the thermistor it shows a correct reading as far as I'm not powering up the 6HC. As soon as it powers the board, it shorts…

Know I've read in an old post, that the negative output of the PSUs (I use more than one) should be connected to ground of the mains input. Could this be the cause?

- Is this ok and still needed?

- Does this also count for the boards in any way (6HC, 3HC and 1LC used)?

- The PSUs have a ground – but on the input (is connected of course)

I don't see how a build-in temp sensor of a heatpad could cause a short? Measurement show no short (measured by the bed), and it's directly connected to the PT100 board. That would mean that a short is passed by the board? This looks strange to me: it starts up – without any feedback?

Thanks for your assistance. Any suggestions welcome…

Tomi -

Please share the results of M122 sent from the gcode console.

Also share your full config.g and the results of sending M98 P"config.g"

A diagram and or photos showing your wiring would be helpful as well. -

Sure – here we go:

M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.4.4 (2022-10-20 16:19:01) running on Duet 3 MB6HC v1.01 (standalone mode) Board ID: 08DJM-956BA-NA3TN-6J9DD-3S86T-KUBGS Used output buffers: 3 of 40 (14 max) === RTOS === Static ram: 152824 Dynamic ram: 98508 of which 204 recycled Never used RAM 96280, free system stack 200 words Tasks: NETWORK(ready,28.6%,210) ETHERNET(notifyWait,0.1%,433) HEAT(notifyWait,0.0%,340) Move(notifyWait,0.0%,351) CanReceiv(notifyWait,0.0%,796) CanSender(notifyWait,0.0%,335) CanClock(delaying,0.0%,340) TMC(notifyWait,8.0%,91) MAIN(running,63.0%,925) IDLE(ready,0.2%,30), total 100.0% Owned mutexes: === Platform === Last reset 00:04:20 ago, cause: power up Last software reset at 2023-02-19 10:39, reason: User, GCodes spinning, available RAM 96484, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 256 MCU temperature: min 25.5, current 27.6, max 31.2 Supply voltage: min 23.7, current 23.9, max 23.9, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.0, current 12.0, max 12.1, under voltage events: 0 Heap OK, handles allocated/used 99/28, heap memory allocated/used/recyclable 2048/386/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, mspos 8, reads 5611, writes 19 timeouts 0 Driver 1: standstill, SG min 0, mspos 8, reads 5612, writes 19 timeouts 0 Driver 2: standstill, SG min 0, mspos 8, reads 5612, writes 19 timeouts 0 Driver 3: standstill, SG min 0, mspos 8, reads 5612, writes 19 timeouts 0 Driver 4: standstill, SG min 0, mspos 8, reads 5612, writes 19 timeouts 0 Driver 5: standstill, SG min 0, mspos 8, reads 5612, writes 19 timeouts 0 Date/time: 2023-02-24 15:46:18 Slowest loop: 28.00ms; fastest: 0.06ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 3.2ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === CAN === Messages queued 2393, received 7312, lost 0, boc 0 Longest wait 3ms for reply type 6053, peak Tx sync delay 6, free buffers 50 (min 49), ts 1301/1300/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 28.32ms; fastest: 0.03ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 = Ethernet = State: active Error counts: 0 0 0 1 0 0 Socket states: 2 2 2 2 2 0 0 2 === Multicast handler === Responder is inactive, messages received 0, responses 0M98 P"config.g" HTTP is enabled on port 80 FTP is disabled TELNET is enabled on port 23 Trigger 9 is not configured Error: in file macro line 34 column 21: meta command: variable 'zendstopx' already existsand

; config.g ; Configuration file for Duet 3 (firmware version 3.3) ; 220508 ; Startup --------------------------------------------------- G21 ; work in millimeters G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Boron" ; set printer name G4 S2 ; CAN expansion pause ; Network ------- M552 P192.168.1.211 S1 ; enable network and set IP address M553 P255.255.255.0 ; set netmask M554 P192.168.1.1 ; set gateway M586 P0 S1 ; enable HTTP M586 P1 S0 ; enable FTP M586 P2 S1 ; enable Telnet ; Drives --------------------------------------------------- ; Z1 | Z2 A B ; 0.1 | 0.2 0.4 0.5 ; ––––––––––––– ; Z0 | Z3 E ; 0.0 | 0.3 121.0 M569 P0.0 S1 ; Z0 physical drive 0.0 goes forwards M569 P0.1 S0 ; Z1 physical drive 0.1 goes backwards M569 P0.2 S1 ; Z2 physical drive 0.2 goes forwards M569 P0.3 S0 ; Z3 physical drive 0.3 goes backwards M569 P0.4 S1 ; A physical drive 0.4 goes forwards M569 P0.5 S1 ; B physical drive 0.5 goes forwards M569 P121.0 S1 ; E physical drive 121.0 goes forwards ; Bindings ------- M584 Z0.0:0.1:0.2:0.3 ; Bindings Z-Motor Board 0 Pin 0 to 3 M584 X0.4 Y0.5 E121.0 ; Bindings other ; Conventionals ------- M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z320.00 E689.00 ; set steps per mm - old E655.0 (221201) M906 I30 ; motor idle current percentage M84 S10 ; Set idle timeout ; velocity, acceleration, and current settings are in these macros M98 P"/macros/drives/xy_fullcurrent.g" M98 P"/macros/drives/z_fullcurrent.g" M98 P"/macros/drives/e_fullcurrent.g" ; GEOMETRY ------------------------------------------------ ; Limits ------- M669 K1 ; select CoreXY mode M208 X0 Y0 Z0 S1 ; set axis minima M208 X300 Y300 Z265 S0 ; set axis maxima (265 with Mosquito, 275 with Dragon) ; Endstops (M574) ------- M574 X2 S1 P"^io3.in" ; X high end, active high M574 Y2 S1 P"^io4.in" ; Y high end, active high M574 Z1 S1 P"^io6.in" ; Z low end , active high ;M574 Z0 P"nil" ; No Z endstop ; Z-Probe ------- M558 P8 C"^121.io0.in" H5 F400 T800 ; Z probe type + the dive height + speeds ; Fnnn Feed rate (i.e. probing speed, mm/min) ; Hnnn Dive height (mm) ; Tnnn Travel speed to and between probe points (mm/min) ; In 1==invert G31 P500 X1 Y20 Z2.5 ; set Z probe trigger value, offset and trigger height ;G31 P500 X25 Y25 Z2.5 ; set Z probe trigger value, offset and trigger height M671 X-70:-70:370:370 Y-5:370:370:-5 S20 ; Define Z belts locations (Z0:Front_Left, Z1:Back_Left, Z2:Back_Right, Z3:Front_Right) M557 X40:260 Y40:260 S55 ; define mesh grid ; THERMIC ------------------------------------------------ ; Heaters M308 S0 A"Bed" P"spi.cs0" Y"rtd-max31865" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 ;M307 H0 R0.474 K0.298:0.000 D2.70 E1.35 S1.00 B0 ; Calibration 220520 ;M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120°C M912 P0 S-0.7 ; Temp correction by Chamber Sensor ;M308 S1 A"Hotend" P"121.temp0" Y"pt1000" ; configure sensor 1 as thermistor on pin 121.temp0 M308 S1 A"Hotend" P"121.temp0" Y"thermistor" T100000 B4725 C7.060000e-8 ; Revo Thermistor M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300°C M912 P1 S-1.1 ; Temp correction by Chamber Sensor M308 S2 A"Short" P"spi.cs1" Y"rtd-max31865" ; define temperature sensor number 2 as a PT100 M308 S3 A"Chamber" P"temp_0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 3 as thermistor on pin temp0 M308 S4 A"MCU" Y"mcu-temp" ; configure sensor 4 as on-chip MCU temperature sens M912 P4 S-4.5 ; Temp correction by Chamber Sensor ; Fans ------------------------------------------------ M950 F0 C"121.out1" Q250 ; PARTS - create fan 0 on pin 121.out1 and set its frequency M106 P0 C"Fan_Part" S0 H-1 ; PARTS - set fan 0 name and value. Thermostatic control is turned off M950 F1 C"121.out2" Q250 ; HOTEND - create fan 1 on pin 121.out2 and set its frequency M106 P1 C"Fan_Hotend" S1 H1 T45 ; HOTEND - set fan 1 name and value. Thermostatic control is turned on M950 F2 C"out1" ; HOUSING - create fan 2 on pin out1 (frequency by S on M106) M106 P2 C"Fan_Hounsing" H4 L0.15 X1 B0.3 T45:70 ; HOUSING - bound on MCU-Tempsensor 40-70°C M950 F3 C"out2" ; EXHAUST - create fan 3 on pin out2 (frequency by S on M106) M106 P3 C"Exhaust" H3 L0.15 X1 B0.3 T25:100 ; EXHAUST - bound on Chamber-Tempsensor 40-70°C ; Tools ------------------------------------------------ M563 P0 S"Revo Hotend" D0 H1 F0 ; define tool 0 REVO Hotend M307 H1 R3.988 K0.554:0.215 D1.84 E1.35 S1.00 B0 V24.0 ;M563 P1 S"Moqsuito Hotend" D0 H1 F0 ; define tool 1 Mosquitto Hotend ;M563 P2 S"Dragon Hotend" D0 H1 F0 ; define tool 2 Dragon Hotend G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C T0 ; select first tool ;M591 D0 P3 C"121.io1" S1 ; filament monitor Duet3D rotating magnet sensor ;M591 D0 ; display filament sensor parameters for extruder drive 0 ; Custom settings ------------------------------------------------ ; -> https://duet3d.dozuki.com/Wiki/Using_M581_-_External_Triggers_and_Building_a_Control_Panel ; eStop Definition -> https://docs.duet3d.com/User_manual/Connecting_hardware/IO_E_stop M575 P1 S1 B57600 ; PanelDue ; Board 1 Board 1 Board 1 Board 1 Board 1 M950 J1 C"1.io0.in" ; B1 «A»: M581 P1 T0 S1 R0 ; -> eStop M950 J2 C"1.io1.in" ; B1 «C»: M581 P2 T2 ; -> trigger2.g "Disable steppers" M950 J3 C"1.io2.in" ; B1 «D»: M581 P3 T3 ; -> trigger3.g "Enable steppers" ; Board 2 Board 2 Board 2 Board 2 Board 2 M950 J4 C"io8.in" ; B2 «1»: M581 P4 T7 ; -> trigger7.g "Homing" M950 J5 C"io7.in" ; B2 «2»: M581 P5 T6 ; -> trigger6.g "Bed meshing" M950 J6 C"io5.in" ; B2 «3»: M581 P6 T8 ; -> trigger8.g "Wipe" M950 J7 C"io2.in" ; B2 «4»: M581 P7 T5 ; -> trigger5.g "Preheat" ; Board 3 Board 3 Board 3 Board 3 Board 3 ; M950 J8 C"1.io5.in" ; B3 «5»: M581 P8 T11 ; -> trigger11.g "Microstep UP" M950 J9 C"1.io4.in" ; B3 «6»: M581 P9 T10 ; -> trigger10.g "Microstep DOWN" M950 J10 C"1.io3.in" ; B3 «7»: M581 P10 T4 ; -> trigger9.g "Stage" <- changed M950 J11 C"io1.in" ; B3 «8»: M581 J11 T9 ; -> trigger4.g "Nozzle change" <- changed ; Misc ------------------------------------------------ M98 P"/sys/set_globals.g" ; load global coordinates and pins ;M501 ; load sys/config-override.g on the SD cardDiagram and photos will follow up…

-

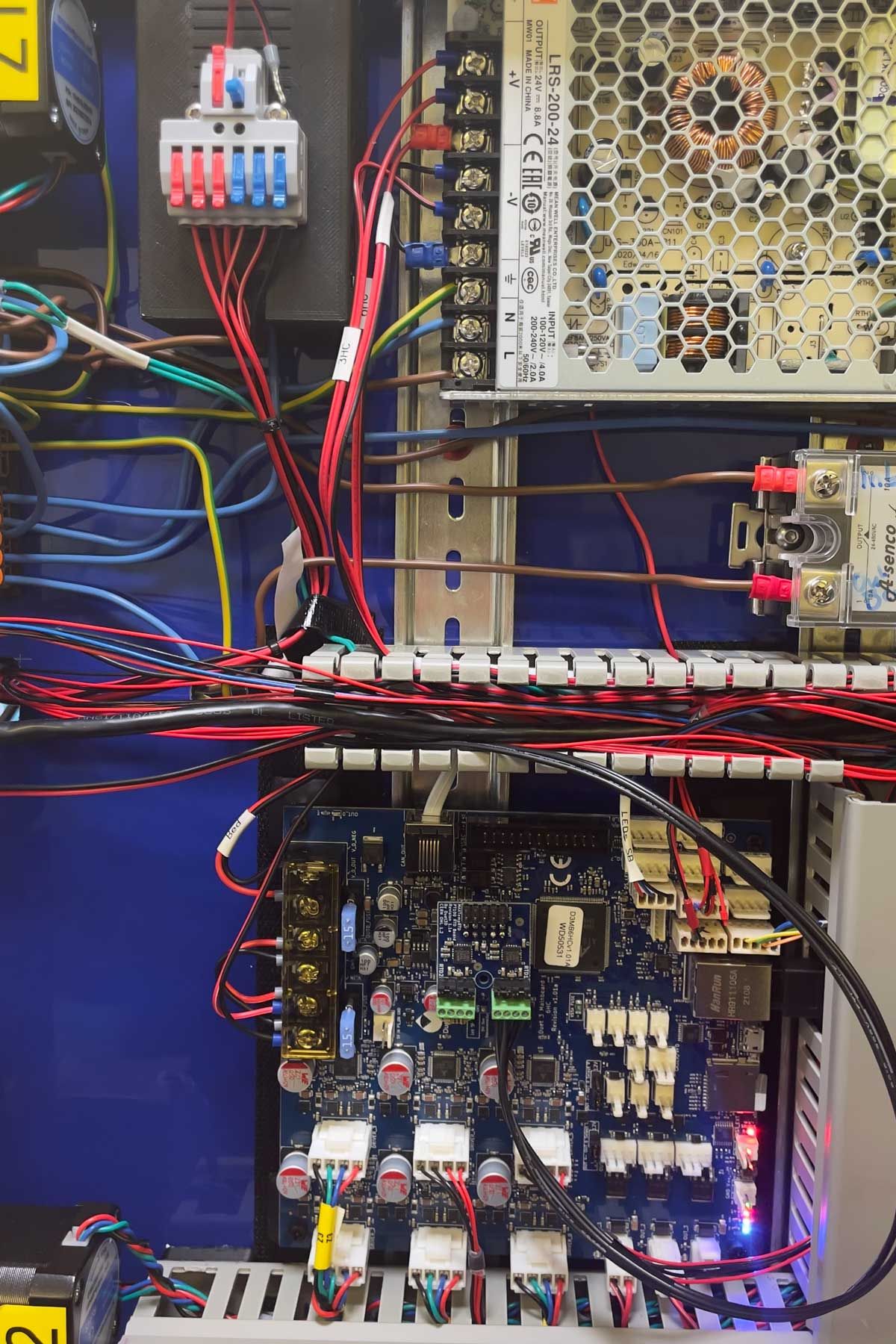

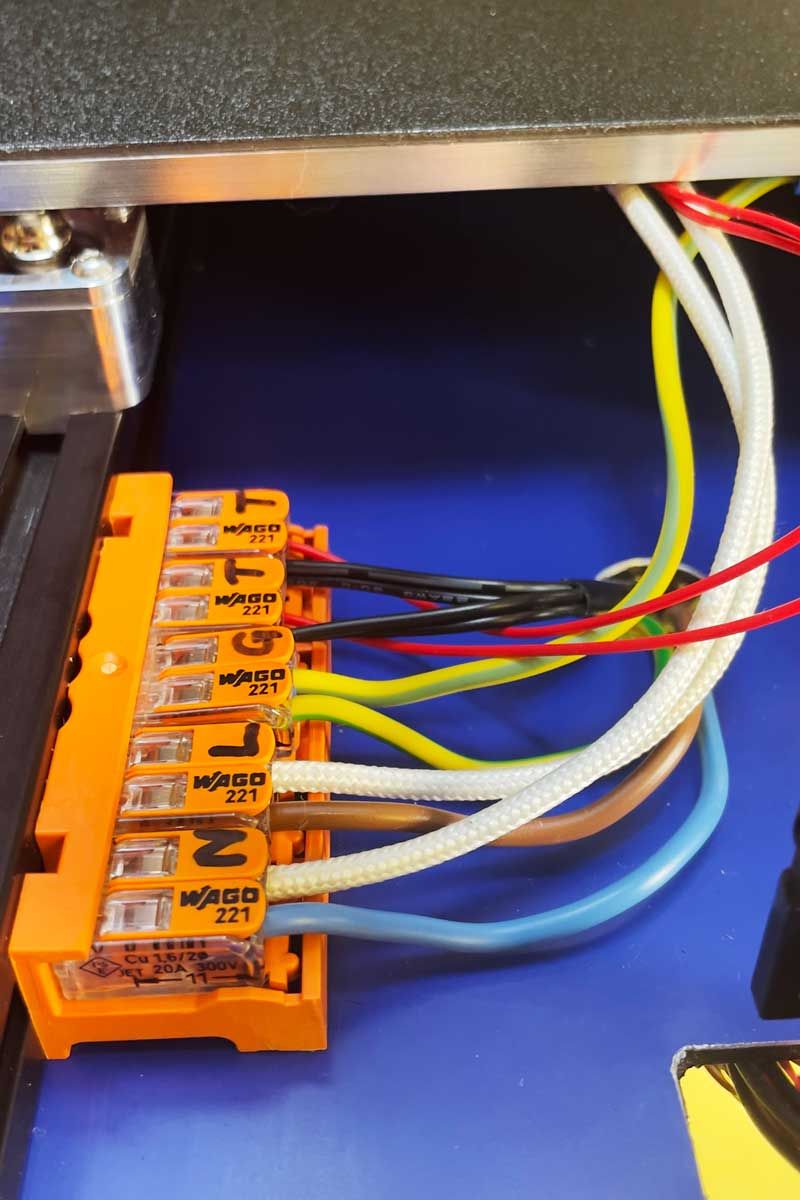

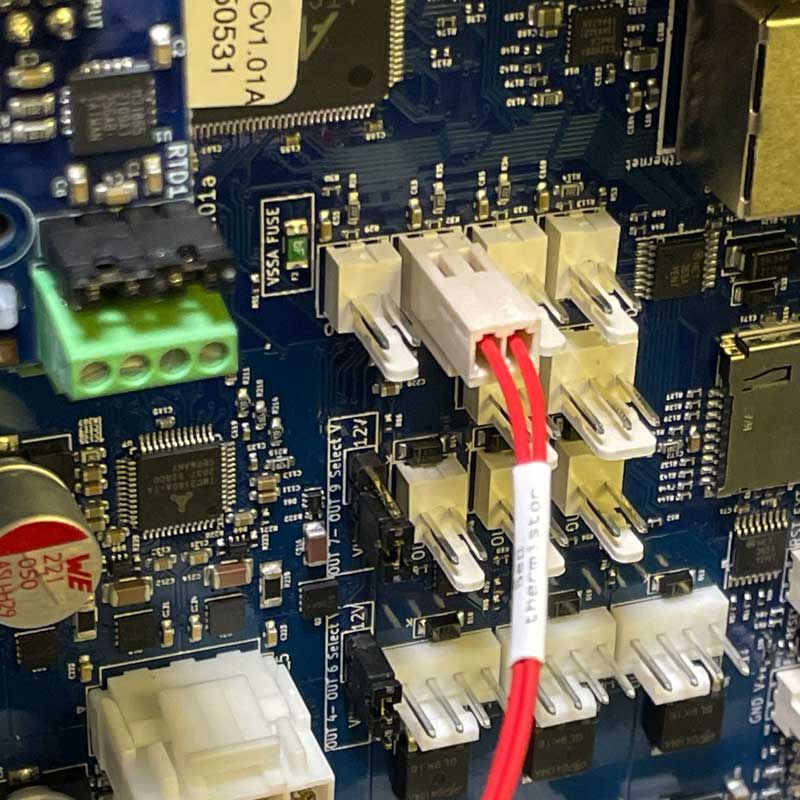

- not all connections done (doing a TAP-rebuild)

- 12V on top left not connected (only lights on this one)

- the double black wires are connecting to the PT100 to the board (as mentioned before)

Does this help to find something?

-

Have you tried the second input on the PT100 daughterboard?

-

Figured out the problem: placed a new heatpad and didn't consider the thermistor could have changed as well! It turned out the PT100 is a PT1000 now.

The solution is simple – if you're able to read your multimeter. Hmm…

Sorry for the fuss – and thank you for your assistance!

-

undefined dc42 marked this topic as a question

undefined dc42 marked this topic as a question

-

undefined dc42 has marked this topic as solved

undefined dc42 has marked this topic as solved