Config.g problem after upgrade FW from v2.05.1 to 3.4.5

-

Hello everybody,

Sorry for my bad english, it's not not my native language. I will try to do my best to explain my 3D printer problems...

So, after upgrading FW from v2.05.1 to 3.0, I have upgraded my Config.g file and change old Gcode to new Gcode commands to be compatible with v3.0 FW.

After some wifi connection problem (no more connection to DWC after upgrade), I decide to use YAT with USB bus to finish my FW upgrade to last version 3.4.5.

The printer is runing, but some bugs are not solved for the moment, I hope you can help me...HW and Software information :

Board : Duet 2 WiFi (v1.02)

FW : RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.5 (2022-11-30)

Duet WiFi Server Version: 1.27The machine is a Delta printer type (3DP ATOM 2.5EX) with Duet2Wifi board.

For me, the FW upgrade is OK, but I have some problems with my config.g file.I have upload the old version (2.0.5.1) and my last version (3.4.5) of the config file to be able to compare the evolution of the system file.

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.3 on Mon Dec 02 2019 23:08:15 GMT+0100 (heure normale d’Europe centrale) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Atom 2.5 EX" ; set printer name M665 R112.5 L225.265 B110 H343 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M551 P"ATOM 2.5EX" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S0 ; physical drive 3 goes backwards M569 P4 S1 ; physical drive 4 goes forwards M584 X0 Y1 Z2 E3:4 ; set drive mapping M350 X128 Y128 Z128 E64:64 I0 ; configure microstepping without interpolation M92 X640.00 Y640.00 Z640.00 E400.00:400.00 ; set steps per mm M566 X6000.00 Y6000.00 Z6000.00 E1500.00:1500.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E9000.00:9000.00 ; set maximum speeds (mm/min) M201 X1200.00 Y1200.00 Z1200.00 E1200.00:1200.00 ; set accelerations (mm/s²) M906 X800 Y800 Z800 E900:900 I10 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z-10 S1 ; set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; set active high endstops ; DYZE Filament SENTINEL Monitor M581 T1 E1 S0 C0 ; DYZE Filament SENTINEL connected to E1_stop ; Z-Probe M558 P4 I1 H3 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z-0.15 ; set Z probe trigger value, offset and trigger height M557 R100 S20 ; define mesh grid ; Heaters M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S230 ; set temperature limit for heater 0 to 230°C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S230 ; set temperature limit for heater 1 to 230°C ; Fans M106 P0 S0 I0 F500 H-1 C"Side Fans" ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 T35:70 H1:2 C"Nozzle Fan" ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on (50% at 35°C) M106 P2 S0 I0 F500 H-1 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R100 S200 ; set initial tool 0 active temperatures to 200°C and standby temperatures to 100°C M563 P1 D1 H1 F0 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R100 S200 ; set initial tool 1 active temperatures to 200°C and standby temperatures to 100°C ; Custom settings G28 ; Home all axes ; Miscellaneous M570 H1 P5 T15 S2 ; Configure heater fault detection M501 ; load saved parameters from non-volatile memory M911 S10 R11.5 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss; Configuration file for Duet WiFi (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Wed Feb 22 2023 20:46:12 GMT+0100 (heure normale d’Europe centrale) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Atom 2.5 EX" ; set printer name M665 R112.5 L225.265 B110 H343.55 ; Set delta radius, diagonal rod length, printable radius and homed height (L225.265) M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M551 P"ATOM 2.5EX" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S0 ; physical drive 3 goes backwards M569 P4 S1 ; physical drive 4 goes forwards M584 X0 Y1 Z2 E3:4 ; set drive mapping M350 X256 Y256 Z256 E128:128 I0 ; configure microstepping without interpolation M92 X1280.00 Y1280.00 Z1280.00 E771,68:771,68 ; set steps per mm M566 X3000.00 Y3000.00 Z3000.00 E1500.00:1500.00 ; set maximum instantaneous speed changes => Jerk (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E12000.00:12000.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z3000.00 E1500.00:1500.00 ; set accelerations (mm/s²) => OLD : M201 X3000.00 Y3000.00 Z3000.00 E1500.00:1500.00 M906 X850 Y850 Z850 E850:850 I10 ; set motor currents (mA) and motor idle factor in per cent M84 S10 ; Set idle timeout ; Axis Limits M208 Z-10 S1 ; set minimum Z ; Endstops M574 X2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop ; DYZE Filament SENTINEL Monitor M591 P1 C"e1stop" S1 D0 ; DYZE Filament SENTINEL connected to E1_stop ; Z-Probe M558 P5 C"^zprobe.in" H3 F120 T6000 ; set Z probe type to switch and the dive height + speeds ;M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved G31 P500 X0 Y0 Z-0.15 ; set Z probe trigger value, offset and trigger height M557 R100 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1:2 T30:50 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H1 F0 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M572 D0:1 S0.2 ; Set or report extruder pressure advance for extruder E01 and E02 => standart value is 0.5 ; Custom settings G28 ; Home all axes M104 S175 ; set standby nozzle temp to 175°C to prevent oozing during homing and auto bed leveling M140 S70 ; set bed temperature to 70°C and bed standby temperature to 40°C ; Miscellaneous M570 H1 P5 T15 S2 ; Configure heater fault detection M501 ; load saved parameters from non-volatile memory M911 S11 R11.5 P"M913 X0 Y0 G91 M83 G1 Z3 E-10 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first toolI try to explain my2 problems :

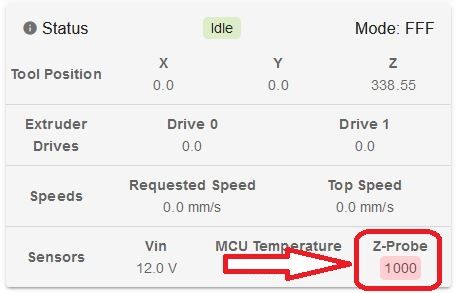

1°/ First, the Z sensor is not correctly configured (it's an Omron optical switch). The Z sensor is always activated (wrong parameter in config.g?), but it must be active only when it is pressed during probing.

I need to invert the Z probe reading signal. I don't find the right parameter/command line on Duet3D documentation (M558 command) to put in my config file...

As you can see the sensor is always active...

=================================================

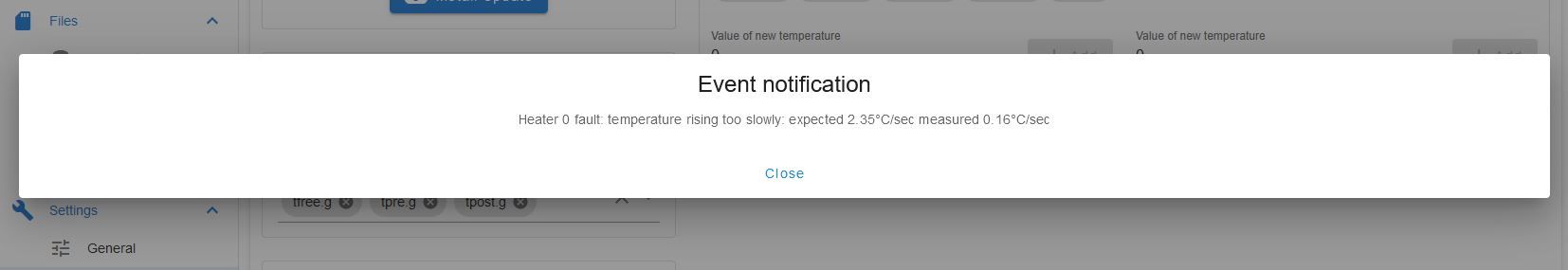

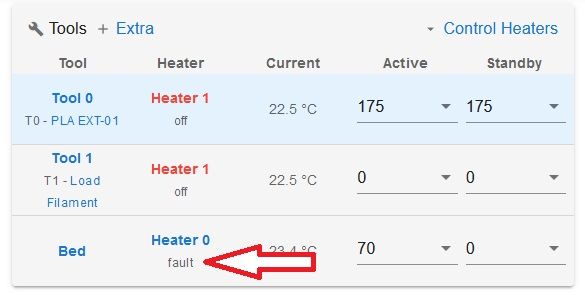

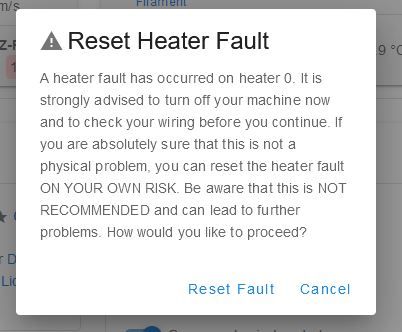

2°/ Second problem I have is this message, but I didn't find the problem or line in link to that in my config.g file.

It's an error message when I try to active the hotbed.

When I reset, I have same error message after several seconds.

Thanks for your support and help.

Regards.

Stephane from France. -

@StAnZ-007 invert a pin with

!egM558 P5 C"!^zprobe.in" H3 F120 T6000I don’t see any M307 commands in your config.g. Have you tuned your heaters? RRF 3.x requires it. See https://docs.duet3d.com/en/How_to_guides/Commissioning#h-6-tune-heaters

Ian

-

I solve the 2 problems now.

Heater tuning OK, and sensor pin was wrrong... My fault...

Thanks, Topic can be closed.

-

undefined jay_s_uk marked this topic as a question

undefined jay_s_uk marked this topic as a question

-

undefined jay_s_uk has marked this topic as solved

undefined jay_s_uk has marked this topic as solved