Test Bed corexy

-

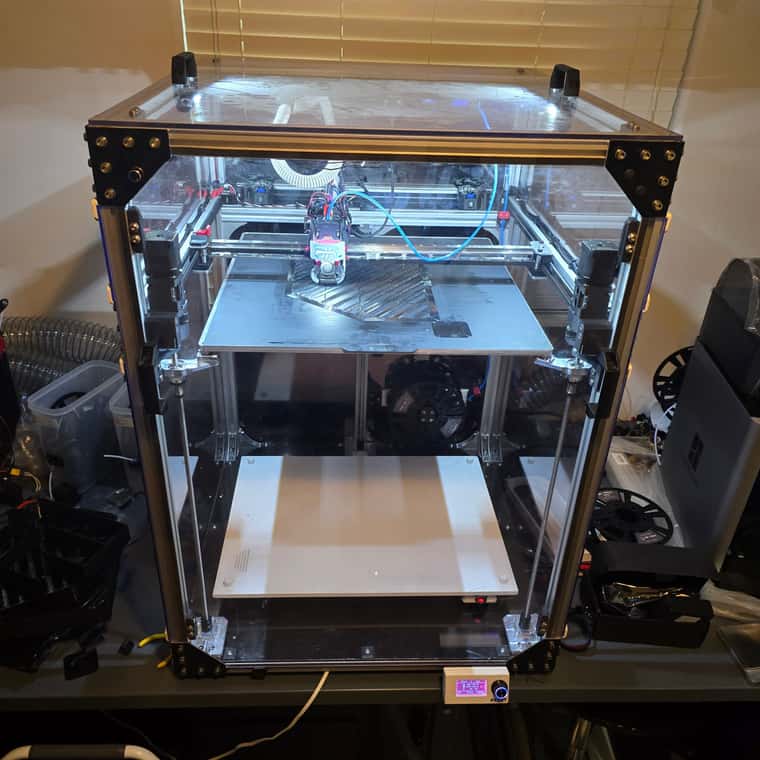

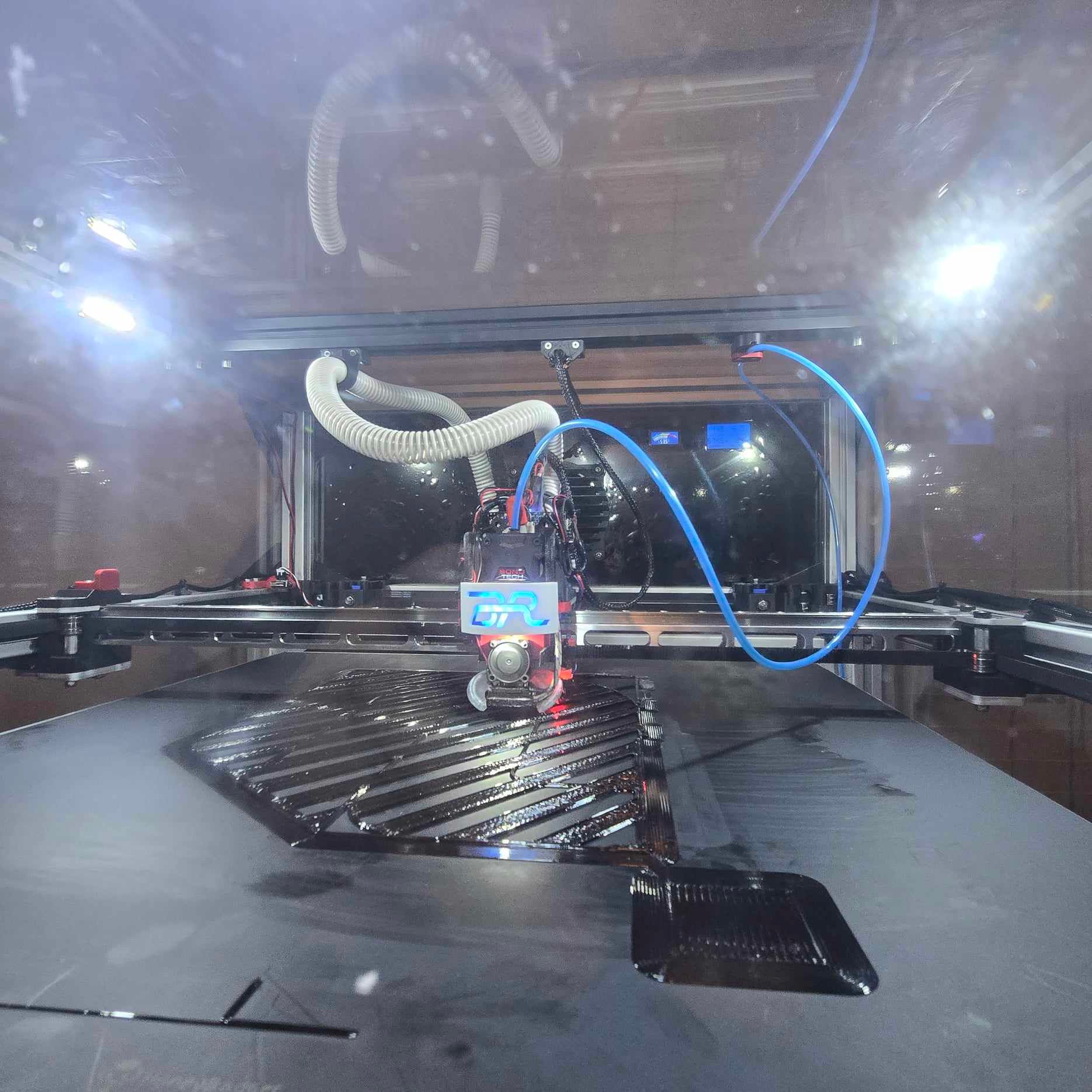

I have been revising and perfecting this first printer build for over a year now through a culmination of knowledge experimentation and research driven mostly by passion. It's a large Ratrig Vcore 3.1 based 500x500mm bed corexy running AWD, and a pogo pin manually interchangeable tool head that I designed. It also has an active heating chamber/ forced air external fume extraction system and high velocity air part cooling system that I designed. All mechanical components are top of the line; this printer performs very well. I am running it with a Duet 3 wifi board, 1LC, as well as Duet's infrared bed sensor and scanning probe. I am no engineer (I hate math), but I am a perfectionist. I usually print ASA and Polycarbonate.

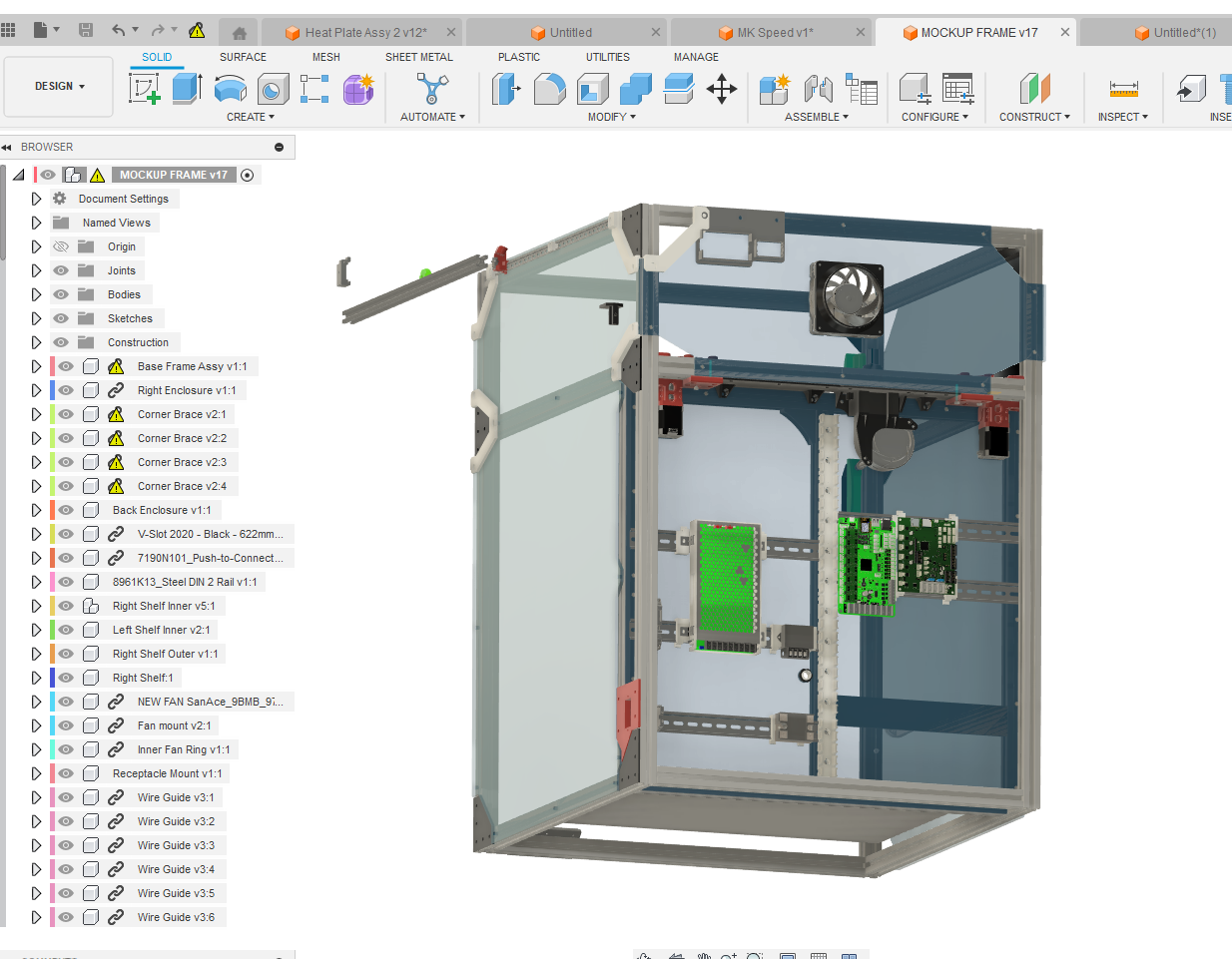

I just started to build printer #2. This printer will be identical mechanically, except running a BTT Octopus board with Klipper through Raspberry Pi. I figure this would create a great opportunity to test bed two mechanically exact identical printers using two different firmware/operating systems side by side.

Its pretty clear that corexy printers are the current performance standard, and larger scale models are in huge demand as they will meet the near future consumer demands of FDM 3D printing.

I'm more than willing to offer my time to work with or help duet engineers later on for side by side testing and comparison, if this configuration will be of any benefit to you.