Mismatching stepper pulley and idler?

-

Surprisingly finding such a simple thing is a PITA online.

I have had 16T pulleys to put in my X/Y axes, but I have 20T idlers, could the angle of which the belt travel have any issues when using them on a Z axis bed Cartesian give me any issues? I'm thinking there is a possibility that the belt will push or pull against the axis.

Thanks.

-

@wyvern Make sure the side of the idler and pulleys has a straight path on the side the belt connects to the z bed.

-

My belt driven bed is fine where it is, I will not be changing that axis.

I'm not sure I understand the answer.

-

@wyvern Have the belt running in a straight line on the side it drives the axis.

-

Well, I'm unable to move the idler or steppers without some modification. Right now it would form a V.

In short it sounds like I will be needing to go .9 in order to increase resolution.

-

@wyvern When it is V shaped, there is a small amount of change in the distance the axis moves between the center and at the end of the axis. You may not see the change in an actual print.

-

-

Yeah, so that's a no-go as I expected.

Looks like I need to save up another $75 for steppers. Trying to get this thing as accurate as possible.

-

Buying different steppers will have no effect in correcting this problem. You have to either accept the small error caused by non-parallel belt path, or make it parallel to the axis.

-

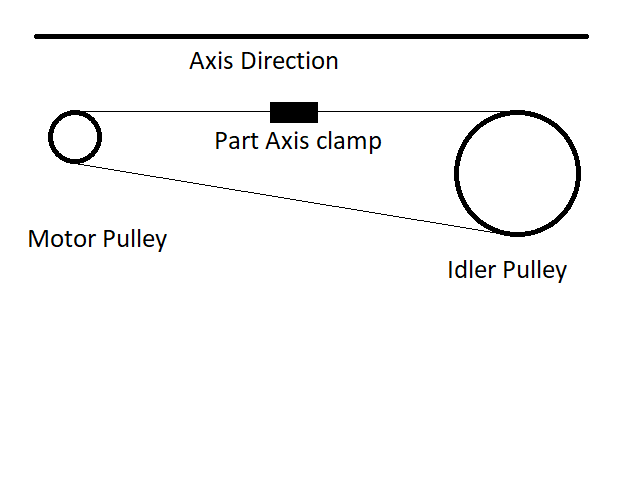

If your axis is aligned like this, it will be okay. With this alignment, the clamp for the X or Y axis will move parallel to the direction of the axis, and even if the other side of the belt does not, it will be okay, so long as that part of the belt does not interfere with anything else.It is probably easiest to get this kind of alignment using the same size pulleys for both, since the centers then are parallel to the axis direction as well, but this kind of alignment is still possible.

If you put the centers of uneven clamps like this, you get funny motion, since the overall length of the belt has to change.

-

@supraguy My setup is good now, 20t/20t.

I asked because I want to bump up resolution and had 16t pulleys.

So without fixing what isn't broken, I will just get .9 steppers.

-

I hope that the belt is straight between the idler and the motor pulley where it's clamped. The rest of the belt path doesn't matter, but if the belt has to deflect to go to the part where it clamps to the moving part, then you will have inaccuracies due to parallax that get worse the closer to the motor end that you get.

EDIT: If the 20T pulleys is how it came initially, then that's probably perfect.