Stealthchop2 to Spreadcycle switch

-

I run stealthchop at quite high speeds. about 80mm/s

When i switched to 0.9degrees steppers the setting was lowered.The problem is that when the driver switch between stealthchop and spreadcycle at high speed this causes a loud noise and in my case layer shifts. After i increased the limit so that it would not switch, i had no layer shifts.

Currently the switch is done via setting the TPWMTHRS parameter and the switch is done by the trinamic driver.

Would it be possible to do the switch based on the requested speed.

So i.e Print move at 60mm/s -> Ok remain in stealthchop

Travel move at 150mm/s -> Switch to Spreadcycle, then move. -

Do you mean switch to spreadCycle at the start of a move that is planned to exceed the threshold speed, instead of switching when the threshold speed is exceeded?

It might be possible, but it would require move-by-move reprogramming of the drivers via the UART. There would be some latency between the start of the move and the command reaching all the drivers. It will be easier to do on Duet 3 because the drivers will use the faster SPI instead of UART for reprogramming.

-

@dc42 said in Stealthchop2 to Spreadcycle switch:

Do you mean switch to spreadCycle at the start of a move that is planned to exceed the threshold speed, instead of switching when the threshold speed is exceeded?

yes with some intelligent logic. i.e if its already in the required mode then dont issue the command.

do you know that the latency would be?

-

Off the top of my head I think the latency should not exceed 10 milliseconds. I will need to check with Trinamic what happens if you reduce TPWMTHRS when the motor is in stealthchop mode and already moving above that speed.

-

from the TMC documentation: https://www.trinamic.com/fileadmin/assets/Products/ICs_Documents/TMC2130_datasheet.pdf

A jerk occurs when switching at higher velocities, because the back-EMF of the motor (which rises

with the velocity) causes a phase shift of up to 90° between motor voltage and motor current. So

when switching at higher velocities between voltage PWM and current PWM mode, this jerk will occur

with increased intensity. A high jerk may even produce a temporary overcurrent condition (depending

on the motor coil resistance). At low velocities (e.g. 1 to a few 10 RPM), it can be completely

neglected for most motors -

This idea really interests me, because I haven't found stealthchop very useful, due to the switch to spreadcycle. Even though it hasn't been shifting layers, it makes a really loud clunk when switching.

Even if I set the V parameter to keep all my 30-50 mm/s print moves in stealthchop, it clunks when making 180mm/s travel moves.

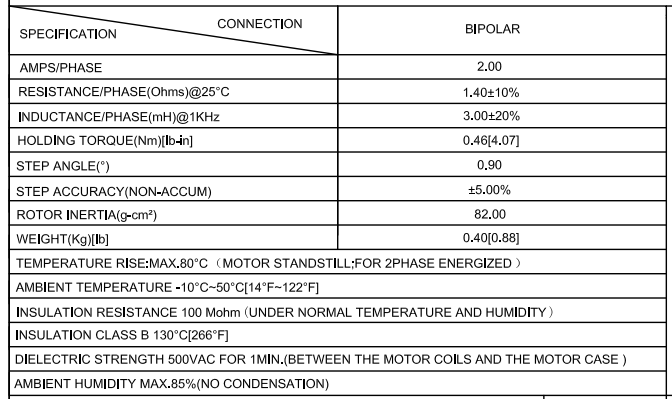

My setup: Ultimaker Original cartesian printer. Running these steppers on X and Y, on a Maestro at 24v on RRF3.01RC11:

Is there some additional tuning I can do to get these steppers working more seamlessly in stealthchop?

-

@CCS86 did you manage to find a solution for this? I experience the same thing with my maestro. For now I have disabled stealthchop2 but would love to use it as it makes my printer very quite.

-

@skezo said in Stealthchop2 to Spreadcycle switch:

@CCS86 did you manage to find a solution for this? I experience the same thing with my maestro. For now I have disabled stealthchop2 but would love to use it as it makes my printer very quite.

I haven't.

Was hoping to get some insight from the devs here, but it's not high on the priorities I guess.