I created this macro to use the mfm to calibrate non linear extrusion. Have done nearly no print tests to see if it actually have a print quality improvement though so feedback would also be appreciated.

; Inputs

var tool = param.T

var maxSpeed = exists(param.S) ? param.S : 20

var dist = exists(param.D) ? param.D : 20

var minExtrusionThreshold = exists(param.E) ? param.E : 0.85

var force = exists(param.F) ? param.F : 0 ; if > 0, will run macro without confirming with user

; Configuration

var baseSpeed = 1

var debug = false

; Internal variables

var originalTool = state.currentTool

var speeds = {1 ,1 ,1 ,1 ,1 ,1 ,1 ,1 ,1 ,1}

var speedInc = var.maxSpeed / #var.speeds

while (iterations < #var.speeds)

set var.speeds[iterations] = var.speedInc * (iterations + 1)

var drive = tools[var.tool].filamentExtruder

var flows = var.speeds ; must be same length as var.speeds

var eMulti = var.speeds ; must be same length as var.speeds

var numMeasurements = 0

; Check with user

if (var.force <= 0)

var msg = "Would you like to calibrate non linear extrusion for T"^{var.tool}^"? Current coefficients: Base="^move.extruders[var.drive].factor * 100^"%, A="^move.extruders[var.drive].nonlinear.a^", B="^move.extruders[var.drive].nonlinear.b

M291 S4 R{"Calibrating Extrusion: T"^var.tool} P{var.msg} K{"Yes", "No", "Reset Coefficients"}

if (input == 1)

M99 ; exit

if (input == 2)

M221 D{var.drive} S100

M592 D{var.drive} A0 B0

M99 ; exit

; Calibrate default extrusion percentage

if (#var.speeds != #var.eMulti)

abort "var.speeds must have the same length as var.eMulti"

echo "Calibrating extrusion rate for T"^var.tool^" using filament \""^move.extruders[tools[var.tool].filamentExtruder].filament^"\""

echo "Settings: distance = "^var.dist^"mm, base speed = "^var.baseSpeed^"mm/s, min extrusion threshold = "^{var.minExtrusionThreshold * 100}^"%"

echo "Speeds: "^var.speeds^" mm/s"

if (sensors.filamentMonitors[var.drive].type != "rotatingMagnet")

abort "Must be a rotating magnet encoder"

if (sensors.filamentMonitors[var.drive].enableMode != 2)

abort "Encoder mode must be S2"

if (sensors.filamentMonitors[var.drive].configured.allMoves != true)

abort "Encoder must be active for all moves (A2)"

T-1

T{var.tool} P0 ; don't run tpre, tfree, tpost

M703

if (tools[var.tool].active[0] == 0)

M568 P{var.tool} S{global.defaultFilamentTemperature}

M116 P{var.tool}

M220 S100 ; reset speed

; M221 D{var.drive} S100 ; reset base extrusion

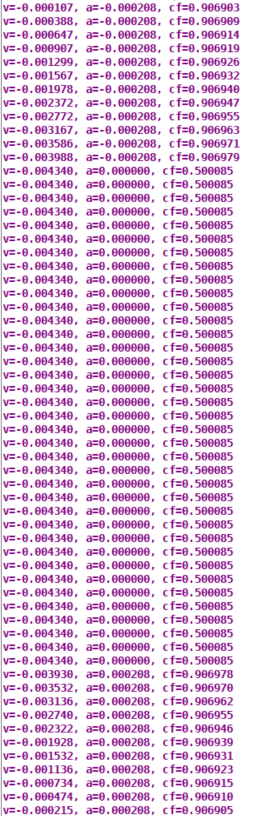

M592 D{var.drive} A0 B0 ; reset non linear extrusion

; G1 X334 Y100 F30000

M591 D{var.drive} S2 A1 ; set magnetic encoder to record during all moves

M400

G1 E{var.dist} F{var.baseSpeed * 60}

M400

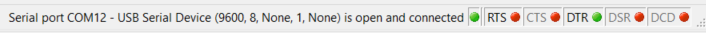

var flow = sensors.filamentMonitors[var.drive].lastPercentage / 100

var baseFlowModifier = {100 / var.flow}

echo "Setting base extrusion factor override for drive "^var.drive^" = "^var.baseFlowModifier

M221 D{var.drive} S{var.baseFlowModifier}

; Collect non linear data

while iterations < #var.speeds

; clear encoder data

M591 D{var.drive} S0

M591 D{var.drive} S2

G1 E{var.dist} F{var.speeds[iterations] * 60}

M400

set var.flow = sensors.filamentMonitors[var.drive].lastPercentage / 100

set var.flows[iterations] = var.flow

set var.eMulti[iterations] = 1 / var.flow

echo "Flow at "^var.speeds[iterations]^"mm/s = "^{var.flow * 100}^"%, requires extrusion multiplier of "^{var.eMulti[iterations] * 100}^"%"

set var.numMeasurements = iterations + 1

if (var.flow < var.minExtrusionThreshold)

break

echo "Number of measurements = "^var.numMeasurements

echo "Flows: "^var.flows

echo "Required extrusion multipliers: "^var.eMulti

; Quadratic regression

; https://www.statisticshowto.com/quadratic-regression/

var x = 0

var y = 1

var x2 = 0

var x3 = 0

var x4 = 0

var xy = 0

var x2y = 0

while (iterations < var.numMeasurements)

set var.x = var.x + var.speeds[iterations]

set var.y = var.y + var.eMulti[iterations]

set var.x2 = var.x2 + (var.speeds[iterations] * var.speeds[iterations])

set var.x3 = var.x3 + (var.speeds[iterations] * var.speeds[iterations] * var.speeds[iterations])

set var.x4 = var.x4 + (var.speeds[iterations] * var.speeds[iterations] * var.speeds[iterations] * var.speeds[iterations])

set var.xy = var.xy + (var.speeds[iterations] * var.eMulti[iterations])

set var.x2y = var.x2y + (var.speeds[iterations] * var.speeds[iterations] * var.eMulti[iterations])

if var.debug

echo "x = "^var.x

echo "y = "^var.y

echo "x2 = "^var.x2

echo "x3 = "^var.x3

echo "x4 = "^var.x4

echo "xy = "^var.xy

echo "x2y = "^var.x2y

; add 100% flow at 0 speed

set var.numMeasurements = var.numMeasurements + 1

; a*var.x4 + b*var.x3 + c*var.x2 = var.x2y

; a*var.x3 + b*var.x2 + c*var.x = var.xy

; a*var.x2 + b*var.x + c*var.numMeasurements = var.y

; Because we have normalised the base extrusion multiplier with a slow extrusion rate

; c ~= 1

var c = 1

; Therefore

; a*var.x4 + b*var.x3 = var.x2y - var.x2

; a*var.x3 + b*var.x2 = var.xy - var.x

; a*var.x2 + b*var.x = var.y - var.numMeasurements

; a = (var.y - var.numMeasurements - b*var.x) / var.x2

; ((var.y - var.numMeasurements - b*var.x) / var.x2)*var.x3 + b*var.x2 = var.xy - var.x

; ((var.y - var.numMeasurements - b*var.x)*var.x3 / var.x2) + b*var.x2 = var.xy - var.x

var b = ((var.xy - var.x) - (((var.y - var.numMeasurements)*var.x3)/var.x2))/(var.x2 - ((var.x * var.x3)/var.x2))

var a = ((var.y - var.numMeasurements) - (var.b * var.x))/var.x2

if var.debug

echo "a = "^var.a

echo "b = "^var.b

echo "c = "^var.c

; Note var.a and var.b are flipped because M592 uses the equation (1 + min(L, Av + Bv^2)) which has different coefficients to that uses to solve the quadratic regression

echo "Setting non linear extrusion multiplier with: M592 D"^var.drive^" A"^var.b^" B"^var.a

M592 D{var.drive} A{var.b} B{var.a}

T-1 P0

T{var.originalTool}

; M591 D{var.drive} S1 A1 ; only monitor filament during prints

The main issue I have identified, which I don't think can easily be solved, is that it doesn't account for how much the filament expands coming out of the nozzle from die swell and foaming. So the extruder might be moving the correct quantity of filament, but the filament becomes a lower density once it leaves the nozzle which effectively produces overextrusion. I think a visual based method would be the most comprehensive way to measure this.

.

.