EMI Testing

Just a quick update on this one. I've done some testing very specifically on the EMI induced in a shielded wire taped adjacent and in very close proximity to the plasma cable. This test cable is a CAT 6 Ethernet cable, where each pair is foil shielded and the whole cable is braid shielded.

Also note that I didn't actually conduct everything in the following order, but I thought it made more sense to present it this way.

Test Setup

I got some interesting results (and way, way more noise than anticipated).

Control

No wires connected to the scope (except the power cord)

Thanks dad for suggesting this one after a mammoth amount of head scratching

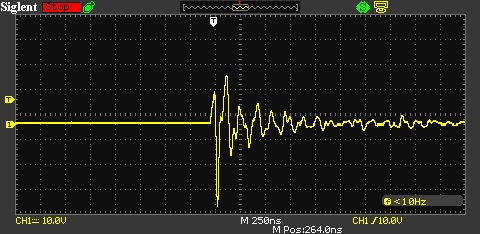

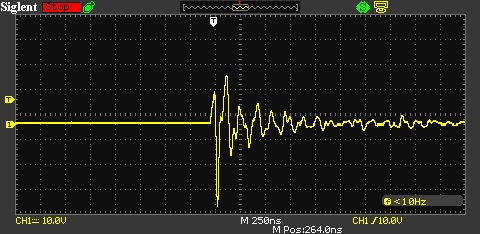

At a (extremely short) peak of ~-40v, I was already surprised by how intense this noise is. Note the scale of the chart is 10v/div and 250ns/div. This pulse however only lasted for less than half a microsecond.

Unshielded Cable

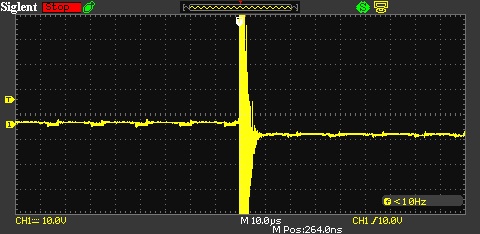

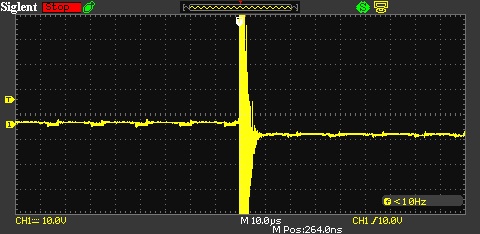

The cable's shield wasn't grounded and instead connected to the signal line of the scope. The scope's ground was earthed.

Peaks are well above 100v and noise is at least 3 microseconds

Shielding

Grounding the shielding substantially improved the noise. Apologies for a lack of photo, I will repeat the experiments tonight and upload another image of the shielded cable for comparison.

The shielding reduced the peaks to ~30v, but this also changed dramatically depending on whether the torch was grounded when the arc was initiated. I believe that preliminary a set of small ceramic capacitors to ground should suitably protect the drivers, but I think I'll be testing it with a stand along step stick and cheapo arduino first!