@bonjipoo, I did. I'm just using a 24V Solenoid air valve (specifically this one: https://amzn.to/35cxang). It's connected to out9 and defined as P3...

M950 P3 C"out9" ; define P3 as mister

Then simply create M7.g and M9.g to turn it on and off...

M7:

M42 P3 S1 ; enable mister

G4 P2000 ; wait for 2 seconds

The 2 second wait just ensures that there's active mist/air before the machine moves on.

M9:

M42 P3 S0 ; disable mister

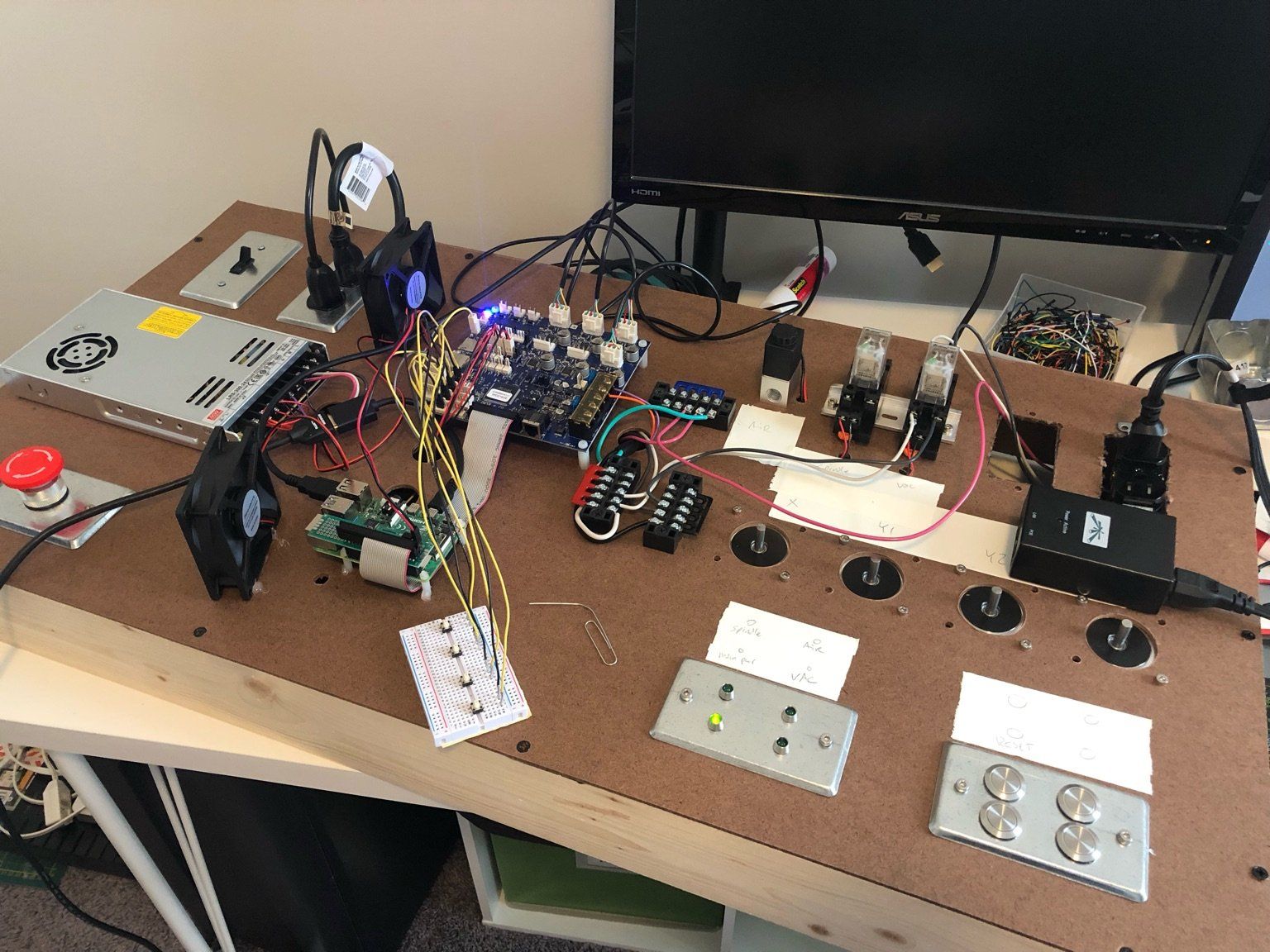

It should be noted that I haven't actually built my machine yet, but I've mocked up all of the electronics and relays on a test bench to prove out my design, and the mister does work (at least in a test setting).