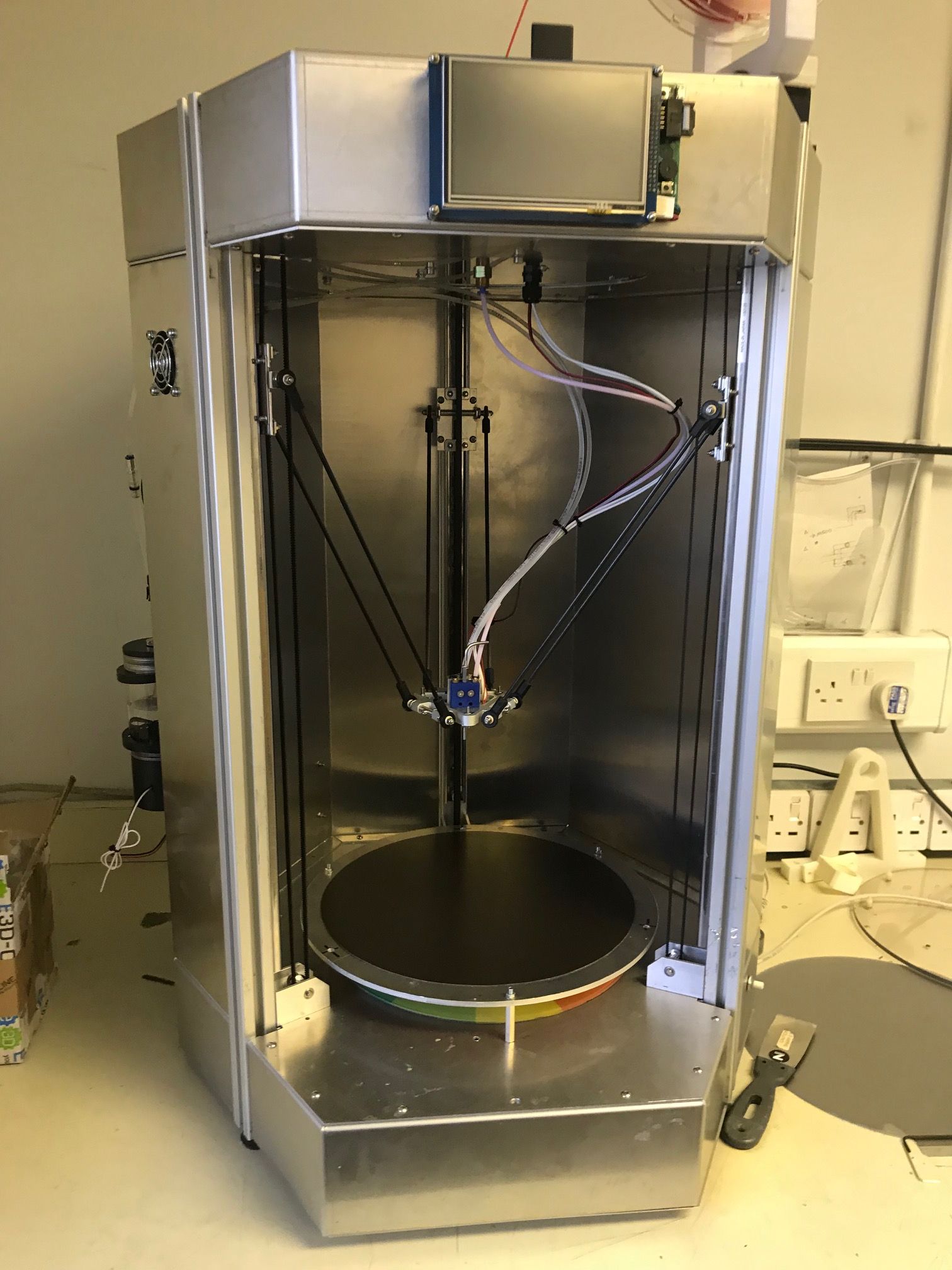

Peek Delta Printer

-

I have been upgrading my delta printer for a few months to print Peek and ultem, its nearly finished, just finalising the z probe although its manual. Just a few covers to print to make it pretty.

Specification:- duet3d ethernet with paneldue

- 500w 240vac magnetic bed good for 150 degrees

- chimera water cooled, upgraded to copper heater blocks, high cartridge heaters and PT100

- manual mechanical z probe

- volume 300mm diameter x 280mm high

- heated enclosed chamber with extraction

Also will be investigating direct heating of the layers as they are printed to increase layer bonding.

-

@andornot, This is a really nice machine!

Small comment however on the un-parallel movement of the skates to the belt. The belt looks to have an angle at the position of the skate. Especially in the low and high Z that will have impact on your layer heights because the angle grows higher at the ends of the belt.

I am interested to se the construction of the skates in better detail. Obviously there are no wheels, but I don't see a linear rail carriage either, it is too thin for that. How does that work?

-

A nice looking machine! But I agree, the two sections of the belt that connect to the carriages need to be in a straight line. Unless you do that, you will get inaccurate movement and varying belt tension. The return section of belt doesn't need to be parallel to those two sections (it wont be if the pulley sizes top and bottom are different).

-

thanks for the advice regarding the belt, i make adjustments to ensure they are parallel. I will keep the post going as testing starts and i learn how to print in peek and ultem.

-

@DeltaCon if you goto my website andornot.co.uk and look at drawing 1-00135 you will see the linear slide and carriageway set up. The linear slide is pre tensioned ball raced, which ensures as it wears its always centralised. I have been using them for years without failure.

-

@andornot said in Peek Delta Printer:

@DeltaCon if you goto my website andornot.co.uk and look at drawing 1-00135 you will see the linear slide and carriageway set up. The linear slide is pre tensioned ball raced, which ensures as it wears its always centralised. I have been using them for years without failure.

Wow, that looks very interesting!

Might be a good alternative for the much more expansive MGN style rails.

Are they as smooth as those?

Thanks for the info! -

@DeltaCon said in Peek Delta Printer:

@andornot said in Peek Delta Printer:

@DeltaCon if you goto my website andornot.co.uk and look at drawing 1-00135 you will see the linear slide and carriageway set up. The linear slide is pre tensioned ball raced, which ensures as it wears its always centralised. I have been using them for years without failure.

Wow, that looks very interesting!

Might be a good alternative for the much more expansive MGN style rails.

Are they as smooth as those?

Thanks for the info!I have never found a problem with them, they cannot take the loading of MGM style rails but for my application they are prefect and reasonable priced.

-

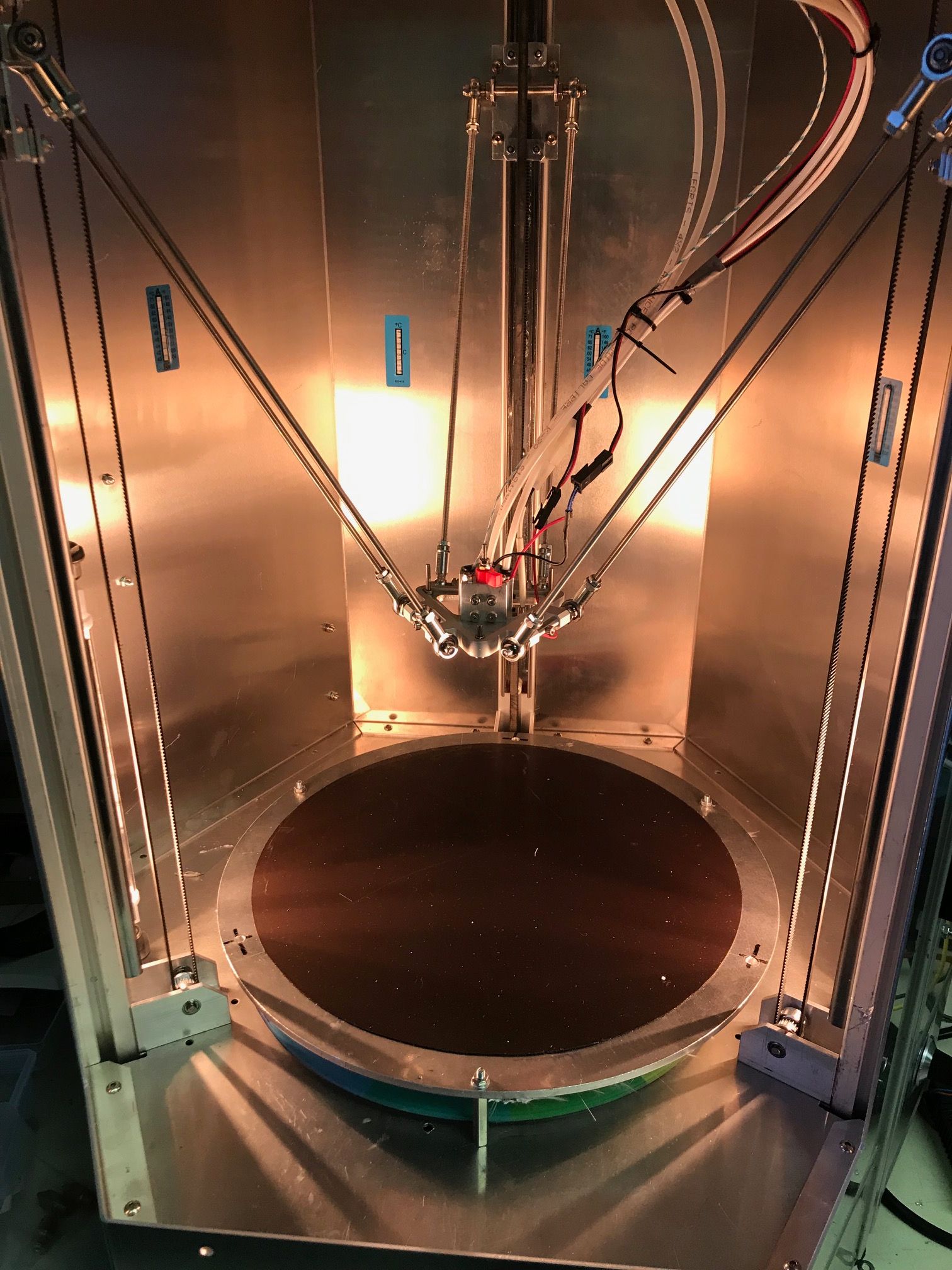

Update to upgrading my delta printer, the design has been refined following been added:

- IR strip lights to heat print to 80 degrees plus

- thermocouple on head to measure print/chamber temperature (yet to control via duet)

- front cover (still needs work to do)

- glass bed

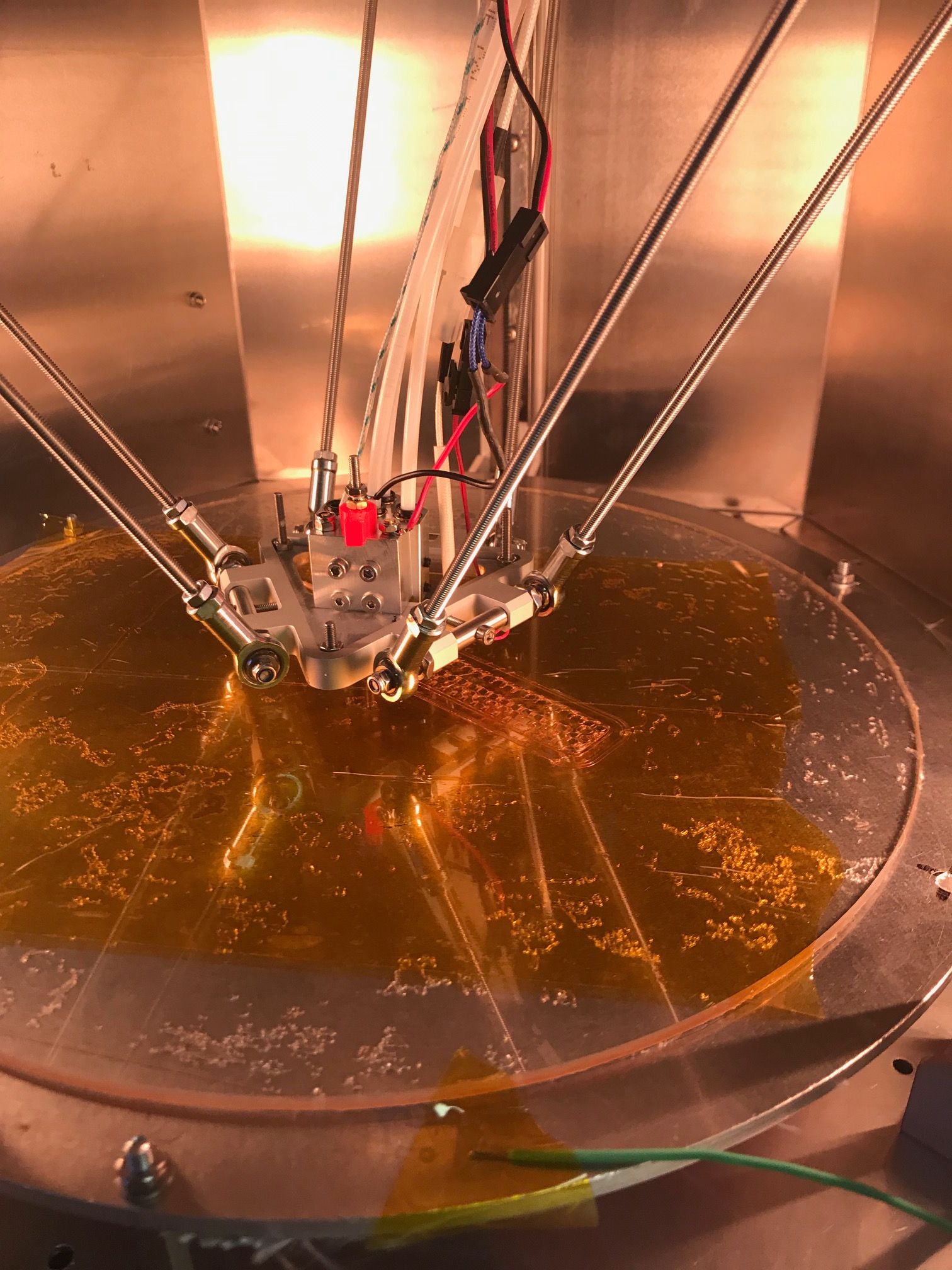

Picture shows it printing with PEKK an electrochemical cell with 150 3mm hexagonal holes, prefect for a 3d printer[0_1576675775058_IMG_2607-s.mov](Uploading 100%)

-

Hey! Those are Misumi PLRH rails! hahaha.... I thought I was the only one to ever use them on a delta! How did you come across them and why did you choose to use them?

I've had a few of the rails wear out on me, so be sure to keep them lubricated and have some spares on hand. They take less load in one moment direction than the other so be gentle!

-

@bot i have been using them for years, i thought nobody else used them. They have lasted years on my machines without failure

-

Glad to hear. I'm only on my second set, since 2015. Not too bad really. It's my fault they wore out. I put a heavy extruder on my effector, which is I think putting too much force in one of those directions. Not bad for the price, for sure! Easy to install and use.

-

Picture below of a test print in Ultem 9085. Its printed on kapton tape with a bed temperature of 150 degrees, hotend 395 degrees and chamber at 115 degrees. The printer has also printed PEEK and PEKK, although PEEK is difficult to stick the bed.

Next i am designing a 200 degree plus vacuum heated bed for plastic films to be printed allowing greater flexible to bed material changes.

-

Nice!

I have a possible print job where Ultem 1010 would suit me well (I need operation up to 200C). I am seriously wondering if I could print that. Heaters are not an issue; bed already does 200C without sweating, hotend (watercooled Chimera) would need a PT100 or thermocouple and possibly a more powerful heater. Not too intrusive or expensive to archieve.

My main issue is the chamber temperature. I have no active heating anymore, so with the bed at 160C the temperature inside the build chamber probably rises to 60-70C or so, but not much further. I wonder if that is enough? Maybe carbon-filled filament would help to reduce warping?

Do you have any experience with that? Ultem 1010 filament is hard to obtain as sample, and the cost of a spool is not at a 'oh well, let's buy one and see where it ends' level.

-

@DaBit i use a water cooled chimera with a pt100 and the high temperature heater, copper heater block and copper plate nozzle available from e3d online. The chamber/print is heated by ir strip heaters which are idea for the delta printer as the bed is fixed.

For ultem 1010 really need a chamber of 110 plus and the cost although for the filament is much cheaper than printing PEEK. Higher the chamber temperature helps layer bonding, stops warping and reduces the thermal stresses in the printed part, although you can anneal it after printing.

What type of printer do you have? Do you have a picture of it? If you are interested in the ir strip setup i post details and suppliers etc.

-

@andornot said in Peek Delta Printer:

@DaBit i use a water cooled chimera with a pt100 and the high temperature heater, copper heater block and copper plate nozzle available from e3d online. The chamber/print is heated by ir strip heaters which are idea for the delta printer as the bed is fixed.

For ultem 1010 really need a chamber of 110 plusHmm. Since I am not planning to print hightech plastics like PEI or PPS on a daily basis I could do the IR temporarily. If I can keep the IR off the print head and illuminate the print only it might work for PEI.

Higher the chamber temperature helps layer bonding, stops warping and reduces the thermal stresses in the printed part, although you can anneal it after printing.

I am not that interested in PEEK yet; it is extremely expensive and the PEEK parts I need can usually be machined quite effectively from round stock or plate.

'lower grade' engineering plastics like PEI and PPS however, well, those would suit me more often. Both for chemical resistance and temperature resistance.What type of printer do you have? Do you have a picture of it? If you are interested in the ir strip setup i post details and suppliers etc.

A DIY printer of course

The printer is a CoreXY, the chamber is closed and insulated. The door is double glass, the aluminium inside is insulated using Armaflex, lighting inside is fluorescent lighting so it can handle some heat as well. But 120C would be too much, it was designed for 90C.

Print head and gantry is made from carbon fiber using a Bondtech BMG-X2 and watercooled E3D Chimera in direct drive configuration.

A CoreXY constructed from tooling plate, Rexroth linear rails and Gates belts move the Chimera around. I used to have to CoreXY motors at the bottom of the printer with shafts running to the CoreXY, but no more.

Filament is stored dry in the printer itself, the filament path to the head is fully enclosed (PTFE tube from filament storage to head)

It used to have a heated chamber, mainly for ABS/ASA, but the airflow gave me too much trouble, and the material choices are not optimal either. Aluminium as carrier for the CoreXY, steel (Rexroth) linear rails, carbon gantry; the thermal expanion coefficients are too different. Oh well, I used what I had or what I could obtain for little money. We all do that. Basically the entire printer structure is built using other peoples trash.

In the end the print results were better by leaving the chamber heater off and just leaving the hotbed running for half an hour to heat the chamber.

So when I rebuild the thing using a Duet and Chimera+ I removed the chamber heater, moved the stepper motors in the chamber close to the CoreXY and used the space taken preeviously by the heater as dry filament storage instead.I think I am going to regret that decision.....

I am contemplating a printer made entirely out of steel using 20mm pitch ballscrews for movement and independent extruders. Then use liquid cooling to keep all stepper motors below 80C, no plastic in the direct drive extruders, and using chamber temperatures way above 100C should not be an issue at all.

But not yet. Such a printer would cost me at least 1500 euros to build. Let's finish this one first and gain a bit more experience. -

@DaBit IR maybe a good for your machine as you are only heating up the part, but your bed moves unlike a delta printer. My machine has a thermocouple on the end effector with a black heatshrink sheath to measure the temperature close to where you are printing and i have been monitoring the sides an they get up to a max of 40 degrees with chamber at 110 degrees. If you go down this route try to eliminate black or dark colours, i have changed most to reflect the IR.

-

The bed moves, but I could locate the IR heaters on the bed itself since I am planning to print fairly flat parts that do not occupy the entire build area anyway. A couple of IR tubes, some aluminium sheet to direct the IR and indeed, a thermocouple to measure the temperature close to the print location and a separate 1/16 DIN controller to control the IR tubes. Hmm, might work, even with low IR intensities. Especially when I try to source carbon filled PEI.

-

The latest upgrade to my high temperature delta print, fully insulated with aluminium backed rock wool. Also i am printing on glass using vision miners nano adhesive to print peek and ultem, its good stuff but not cheap, i would certainly recommend it.

-

It certainly looks nice.

No issues with the belts and higher temperatures? -

@DaBit they are holding up but i am changing the design to move the slideways and belts to the outside of the machine. It will look ugly and fit for function long term i will redesign, this will allow 200 plus temperatures in the chamber.