Steppers PID - NOT heaters PID

-

@Bogdan said in Steppers PID - NOT heaters PID:

@bearer From what I know, the servos cost a lot. I was thinking that maybe there would be some way to obtain an accurate position from the trinamic driver, thus eliminating the need for an encoder or expensive servo assembly.

trinamics are truly great, but the StallGuard feature isn't suited for low speed, so you'd loose control before coming to a stop, or at tight corners f.ex.

-

I have been able to completely alleviate any visible ringing from my prints by choosing a very low instantaneous speed change value for X and Y, as well as a conservative acceleration value of 1200.

"Jerk" and acceleration are what excite the ringing/ghosting on direction changes. It may be belt stretch, it may be lag and lead of the rotors in the motor... either way, if you want to eliminate you must adjust the jerk and accel.

I get "perfect" prints (ignoring bulges of extrusion at the corner) at 100 mm/s prints speeds with jerk of 8 mm/s and accel of 1200 mm/s/s. To alleviate the bulging extrusions, pressure advance works perfectly. (Though, PA slows down lower resolution prints on my machine due to extruder limitations. At high resolution, this slow down does not occur.)

-

Thank you all for your insights.

I read a few more things on the DUET forums and other forums and I'm starting to think that implementing a PID for motion planning may not bring so many benefits. It would be complicated to implement, and the speed gains would be marginal. (It may already be implemented in LinuxCNC, but I didn't look into the details).

Still, while reading, I read a bit more about TinyG and the way they handle the higher order derivatives, as was suggested by @Danal . Their implementation detail is here: https://github.com/synthetos/TinyG/wiki/Jerk-Controlled-Motion-Explained . The major advantage of their implementation is that it smooths the movement, so less force would be put on the belts, which in turn would cause them to not stretch that much, which in turn would provide more accurate prints. There was some talk about it last year on this forum https://forum.duet3d.com/topic/4802/6th-order-jerk-controlled-motion-planning , but I don't think it was implemented.

Other than that, maybe the idea of reading the motion feedback would not be that bad, provided the printer is rigid "enough". Using some carefully chosen calibration movements before printing would allow people to calibrate the motion parameters, thus determining optimal settings for speed, quality, or different trade-offs between them. Maybe this could be implemented as a separate (slave) module connected to the main board via CAN...

-

@Bogdan said in Steppers PID - NOT heaters PID:

some carefully chosen calibration movements before printing

During commissioning. Setting parameters that are important to that physical printer, but don't change often.

Hmmm... very good idea. I wonder if it could even be "feedbackless" in terms of an actual electronic sensor, and instead based on something the human observes.

Hmmm...

-

We have plans for CAN-connected stepper driver boards with encoder inputs next year. So closed loop control will be possible, using linear encoders to track the axis position.

-

@Bogdan said in Steppers PID - NOT heaters PID:

(It may already be implemented in LinuxCNC, but I didn't look into the details).

for servos only.

I think you are missunderstanding the basics

"motor pid" is positioning them, with stepper that makes zero sense, you know where stepper is.

what's mentioned further is the way movement is calculated (constant jerk, trapesoid, S curve, junction deviation etc etc ..) and that's a completely different thing.. it's where 3d printing path calculators are behind some professional cnc machines but that's mostly 'cause it would bring nothing or close to nothing to 3d printing story (our lateral forces are pathetic compared to milling machines). we are much closer to engravers than to mills and you will not find these calculations there neither..

the ringing you mention has very little to do with this (nothing to do with videos you linked). maybe S shape will reduce ringing but that's minimal, ringing is caused by shitty parts used on most printers... GT2 belts used 'cause they can bend over a tight radius, but they normally stretch and that equals ringing... you can find glass enforced GT2 but it's rare, expensive and not mounted to any of the printers I seen so far (from prusa & ultimaker to super cheap PRC stuff) ... the new E3D machine supposedly comes with german GT2 that's reinforced, we'll see how it behaves when it arrives.. but look at your regular cheap popular printers these days (ender 5, ender5s, wanhao d9, creality cr10 etc etc..) there is a SPRING on the each belt!!!!!! there's no electronics that will remove ringing produced by those springs, the only thing you can do there is crawl to halt (reduce acceleration to nothing and jerk/junction deviation to zero

)

) -

@smece said in Steppers PID - NOT heaters PID:

... you can find glass enforced GT2 but it's rare, expensive and not mounted to any of the printers I seen so far (from prusa & ultimaker to super cheap PRC stuff) ...Almost all GT2 belts, even/especially the cheap ones, are glass reinforced. You can also find kevlar and steel reinforced belts.

You can consider the presence of clothespin spring tensioners a sign of a bad design. Recently I've only seen them on corexy machines where the pulleys were not positioned to keep the belts parallel to the guide rails. In such machines the belt tension will vary with the position of the extruder carriage. In that case they may be needed to keep the belt tight enough to drive the mechanism at all extruder carriage positions.

-

Genuine "GT2/3" belts (3 is the latest rev) ONLY have glass fiber reinforcement. Anything else is not made or designed by gates. No steel, nothing.

-

@mrehorstdmd said in Steppers PID - NOT heaters PID:

Almost all GT2 belts, even/especially the cheap ones, are glass reinforced. You can also find kevlar and steel reinforced belts.

don't have to take my word for it, test it your self. the belts on

- cr10

- cr10 500

- wanhao d9 300

- wanhao d9 500

- wanhao i3

- malyan m150

- monoprice select

...

every single of those printers comes with belts that stretch

all the cheap aliexpress stuff (e.g. https://www.aliexpress.com/item/32811803594.html ) are belts that stretch

when you compare that with proper original gates or similar reinforced japanese belts you figure out the difference but the problem for most ppl is no frame of reference as I'm yet to see a printer that arrives with original gates ...

don't confuse the pathetic textile mesh embedded in the PU as reinforcement

just measure the stretchiness of the belt itself... when you work with them for a while you can also tell by the sound they make...

just measure the stretchiness of the belt itself... when you work with them for a while you can also tell by the sound they make...now apart from shitty belts, the huge issue comes from shitty pulleys too (yes there can be a backlash in the pulley too, you can see that very easy on the laser engraver, or even more 3d printer with laser head) ... it's not that pronounced but it is there

the cheap belts that have proper armature start at 5mm / 0.2" pitch, problem with them is they can't bend around tight radius so you need to use large (18-20 tooth pully is minimal radius for proper 5mm belts)

-

@mrehorstdmd said in Steppers PID - NOT heaters PID:

You can consider the presence of clothespin spring tensioners a sign of a bad design. Recently I've only seen them on corexy

I'm yet to see a machine coming from the East that does not use them. It's a typical partner to shitty stretchy belts

-

@bot said in Steppers PID - NOT heaters PID:

Genuine "GT2/3" belts (3 is the latest rev) ONLY have glass fiber reinforcement. Anything else is not made or designed by gates. No steel, nothing.

there are also few other manufacturers (there's one in Japan) that make reinforced 2mm pitch belts so gates are not the only one. but yes, only a few very big (and expensive) manufacturers make 2mm pitch belts that are reinforced, rest are classic PU belts with (or even without) classic stretchy cloth

as for the steel, you can't have steel in 2mm pitch belt as bend radius of the 2mm pitch belt is low (around 15mm iirc) and steel would break after some hours of usage, that's also why most of the 2mm pitch belts are without any reinforcement as glass/kevlar is expensive to make properly and other materials won't work properly for that small bend radius

-

@smece I was only talking about official gates GT2/3 belts. FYI, GT2/3 can come in 2, 3, 5, 8, 10 (iirc) tooth pitches. The GT2/3 just refers to the specification of the belt, which includes all the construction material.

I believe gates does licence the rights to manufacture belts accoring to their GT3 specification. GT2 is deprecated (but the pulleys remain cross-compatible, IE there is no GT3 pulley). The principal difference that matters to machine design, iirc, is that the thickness of the belt changed in GT3. Backside idlers ned to be spaced slightly differently, if that's important.

Another piece of belt trivia: there is no open loop belt that is genuine GT2/3. AFAIK, they only come in specific continuous lengths. This is because each length has its own mold, and is the entire circumference of a circle, whereas the (cheap, fake) open-loop belts are spiral cut from an arbitrarily sized cylinder.

-

@bot they probbly do sell licence but many that bare their name are not made to spec

as for close/open, dunno bout gates, I have seen how they arrive into local shop (they import from sweden) ... they come in both open "carpet" shape (2m wide, many m long rolled carpet) and in "tubes" of number of diameters, also 2m wide .. but for e.g. the smallest pitch is 5mm that manufacturer doesn't have anything below 5mm

-

@smece said in Steppers PID - NOT heaters PID:

all the cheap aliexpress stuff (e.g. https://www.aliexpress.com/item/32811803594.html ) are belts that stretch

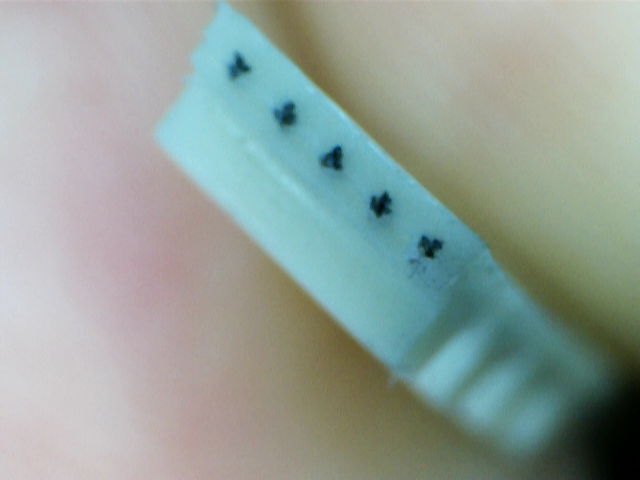

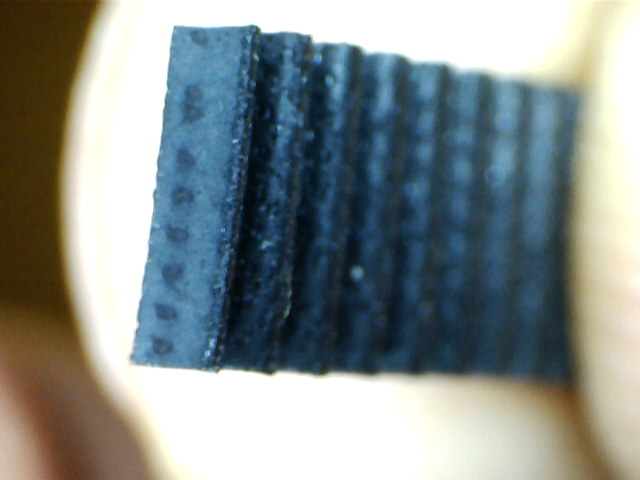

If you look at the numerous photos of the belts you linked, you can see some brown material at the edge of the belt in some areas. That is one of the glass reinforcement cords in the belt. You will see the same thing in genuine Gates belts. I don't know what your reference is for stretchiness is, but the example you linked is definitely glass reinforced. I have purchased and used such belts numerous times, as well a Gates belts, and examined samples of both under a microscope:

That's Gates LL2MR09 on bottom and generic Chinesium on the top.

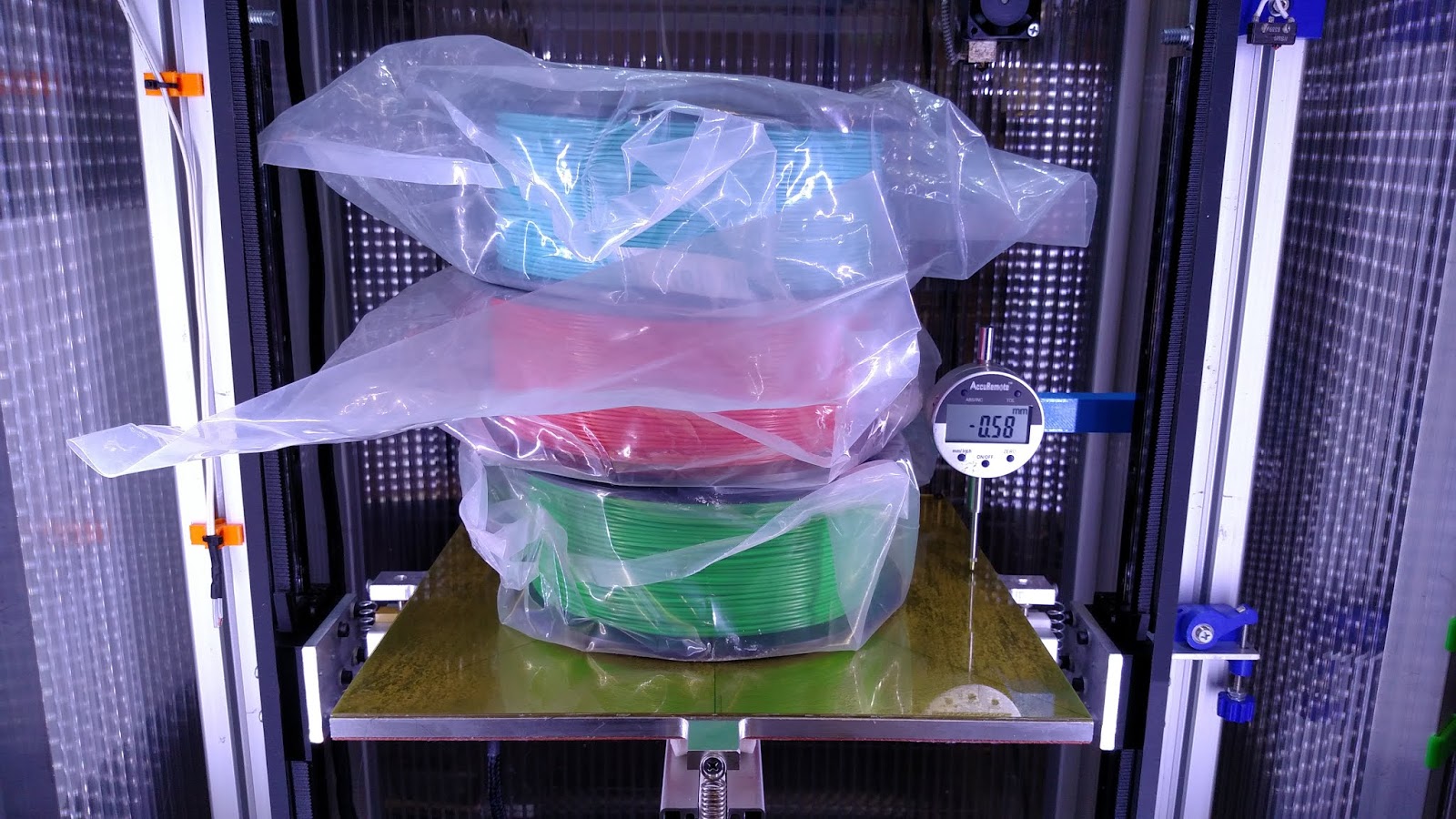

I have also measured belt stretch under static conditions and found that pairs of Gates LL2MR09 that are about 1m long stretch about .145 mm/kg of static load. The total load was about 7.5 kg, but my reference point was at about 3.5 kg of load plus whatever tension was applied- probably a few more kg- the additional 4 kg added 0.58 mm stretch.

-

Belt stretch on a 3D printer? Nah - doesn't happen with timing belts from a reputable source. I use 6mm wide belts and throw 2 Kgs of hot end around (plus 3 Kgs of extruders on a separate gantry) at non-print move speeds of 350mm/sec - no belt stretch whatsoever in evidence.

Coming from an automotive background, I was highly dubious when "traditional" steel timing chains that connect the crankshaft to the camshaft started to get replaced with belts made from reinforced synthetic rubber back in the 70s or early 80s. The reason for my reservations was that the torsional forces imparted by heavy valve springs acting on cams is immense especially when you start rotating that at 6,000 rpm or so. Those forces are thousands of orders of magnitude higher than anything we'd every see on a 3D printer (although the belts are wider). But now 40 years later, I can see that my fears were unfounded because no engine that I know of uses chains (now they would stretch because the link pins used to wear).

-

@deckingman said in Steppers PID - NOT heaters PID:

Belt stretch on a 3D printer? Nah - doesn't happen with timing belts from a reputable source.

exactly my point "reputable source"

reputable:

ender 5

noname aliexpress "double price" (marked as high quality) pack for corexy

wanhao i3

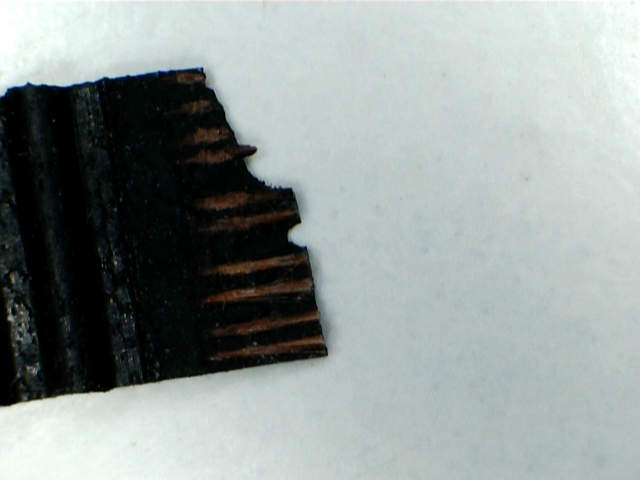

as you can see there's nothing in the e5 belt for e.g.

the wanhao i3 belt have "something" as reinforcement, that "something" is not glass/kevlar as when you clean the rubber and get to it you find it's syntetic rope hence the stretching

just do a simple test take 1.2m of the belt stretch it over 100cm board, put a pulley at the end, get belt over it and on that 20cm connect a scale. then link the belt around the pulley to indiator and null it, load the scale slowly and measure how much the belt stretch for each weight you add .. do that for few different PRC belts and do it with gates (unitta) or any other brand name and compare results ... I did .. 10kg on gates and my 0.001mm indicator did not move .. these "syntetic rope" reinforced ones and it starts moving after 100g

extract the reinforcement from generic belt

you will see it's not glass, it's standard syntetic rope