Delta printer belts and 16 tooth pulleys

-

@Danal said in Delta printer belts and 16 tooth pulleys:

Hmmm... if they are that rare, then here is one more. This is the one I've been running, modified to be 8mm core. This MIGHT cause issues with the 3mm tension screw; may have to go to 2mm screw.

As you suspected, thinning out the core creates a problem with the M3 tension screw. A 3mm hole in a 4mm block of plastic doesn't work well.

What might work instead is to instead thin out the "wall" that runs the entire length of the carriage (which is 3mm thick in the stl's you posted) to 2mm and then thicken the traveler and section where the M3 screw goes up to 5mm (from 4mm in the files you posted.) That might require shifting everything to one side.

How does the traveler work on this? Do you glue the nut in place on the carriage?

I might mock up something similar tonight or tomorrow and see how it works out.

-

The nut tends to stay in place.

This is all openSCAD by the way, I can post those files as well. I did not, because the forum won't accept that file extension and I will have to zip them or something.

I'll change the various widths in a few min.

-

@Danal said in Delta printer belts and 16 tooth pulleys:

I will have to zip them or something.

It won't take zip files either. You'd have to change the extension to .txt or something or host it elsewhere and link it.

-

I have added .scad to the list of allowed file extensions.

-

THANK YOU!! What a rapidly delivered 2020 gift!

-

Updated for 2mm buffer, 1mm space for belt, 5mm clamps and travelers. 8 total.

Carriage for HWIN 55mm Mag 9mm belt V6.stl

Carriage for HWIN 55mm Mag 9mm belt V6.scad

-

@Danal This looks good. Thank you. Is there a different scad file for the traveler?

Also, I'm wondering what plastic you used to print this. While I might tend towards ABS or PETG for "workhorse" parts, I wonder if PLA is better due to the need for exact spacing on the magballs, and for the hardness of PLA (so the magballs don't flex with movement..)

-

I used PLA.

I will update the traveler in a few min (just forgot that it's width needed to change as well.)

-

@Danal said in Delta printer belts and 16 tooth pulleys:

I used PLA.

I will update the traveler in a few min (just forgot that it's width needed to change as well.)

Modified from the file on thingiverse.

Carriage_for_HWIN_55mm_Mag_6mm_belt_-_Traveler.scad

Thank you!

-

Thanks, @garyd9, obviously I got sidetracked.

Thanks again.

-

I just checked my delta. You are right, they do rub slightly. The machine might be a little quieter if they didn't. It looks like there is enough material so that the part that touches the belt could be milled down a little.

-

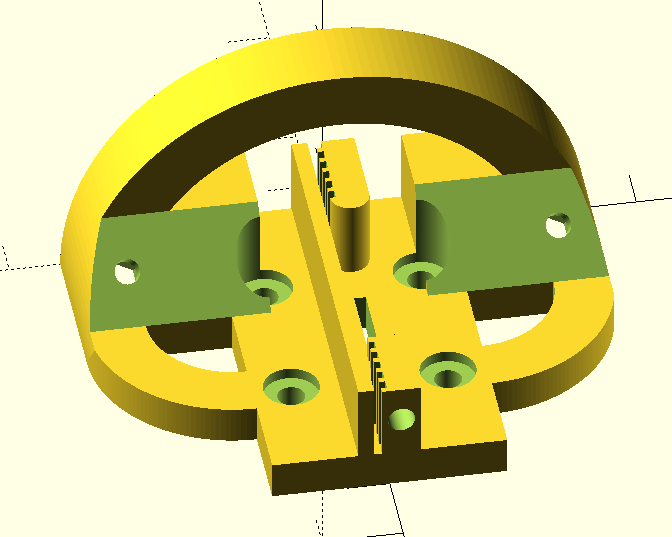

@Danal , I'm still working with your model to make it printable with the 8mm center core. (The nut slot doesn't print well as-is when it's thinned down.)

In the meantime, I thought I'd post what I'm currently using (for the last 6 hours.) It takes into account that my belt is 20mm away from the vertical tower and that the linear rail assembly is 13mm. (The model is actually two pieces: a base part with a rectangular 20mm hole pattern and a tensioner with a slot for a M3 nut.) The slots for the 2GT belts are very precisely measured and tested to work with "Gates" 2GT belts sold by E3D.

I sandwich the smart effector carriage adapter between the rail carriage and the base of this tensioner model. (I also use 4mm shims between the magballs and carriage adapters.)

After the the sandwich is tightened down, I can slide the tensioner part of the model between the base and smart effector carriage adapter.

The model started from the .STEP file attached to this thingiverse thing: https://www.thingiverse.com/thing:3546124, and was completely redone for belts, spacing, etc.