Technical defect?

-

@GuybrushTreepwood Lovely name, I'm a Monkey Island fan too! Though it's Threepwood!

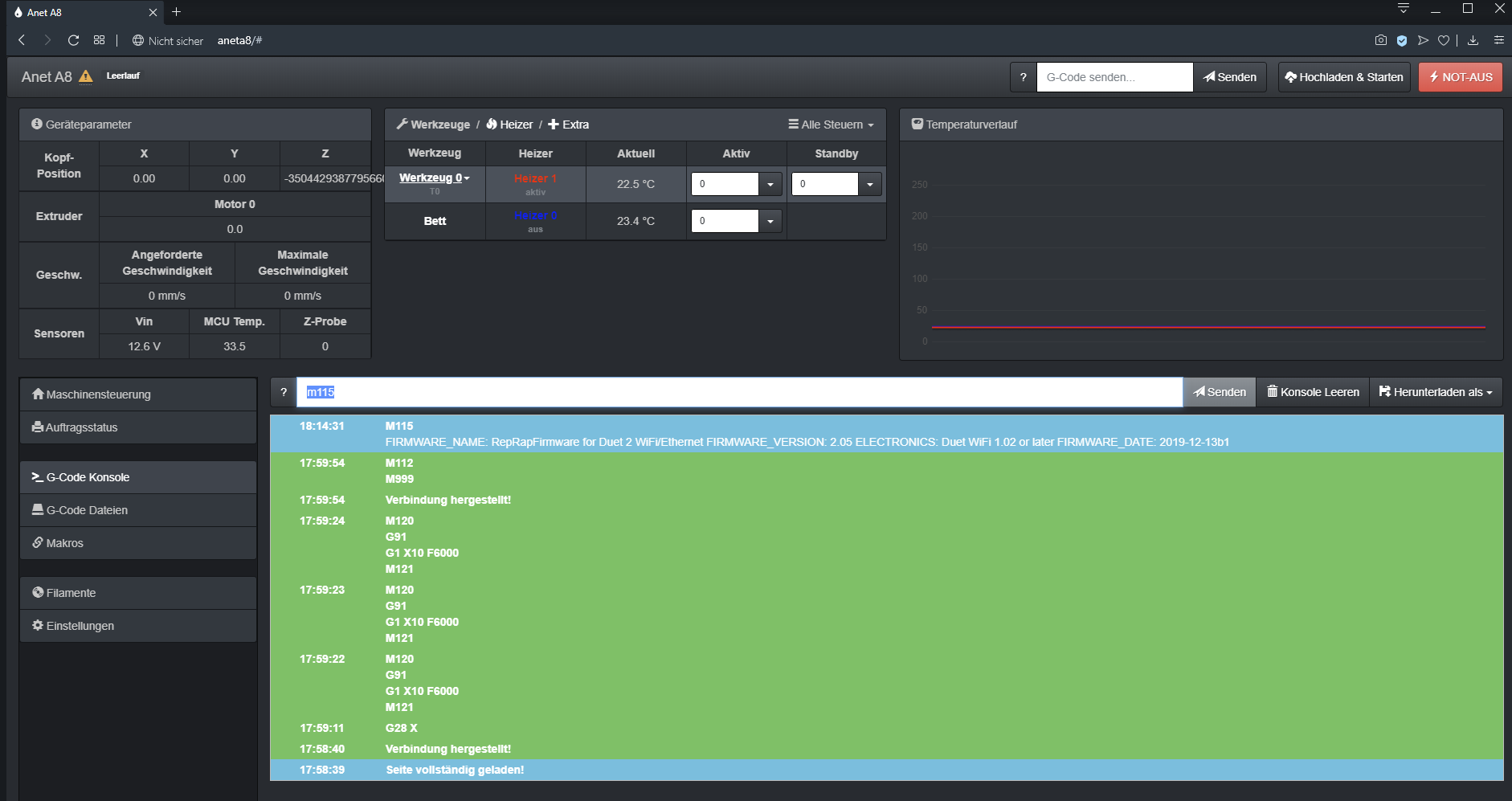

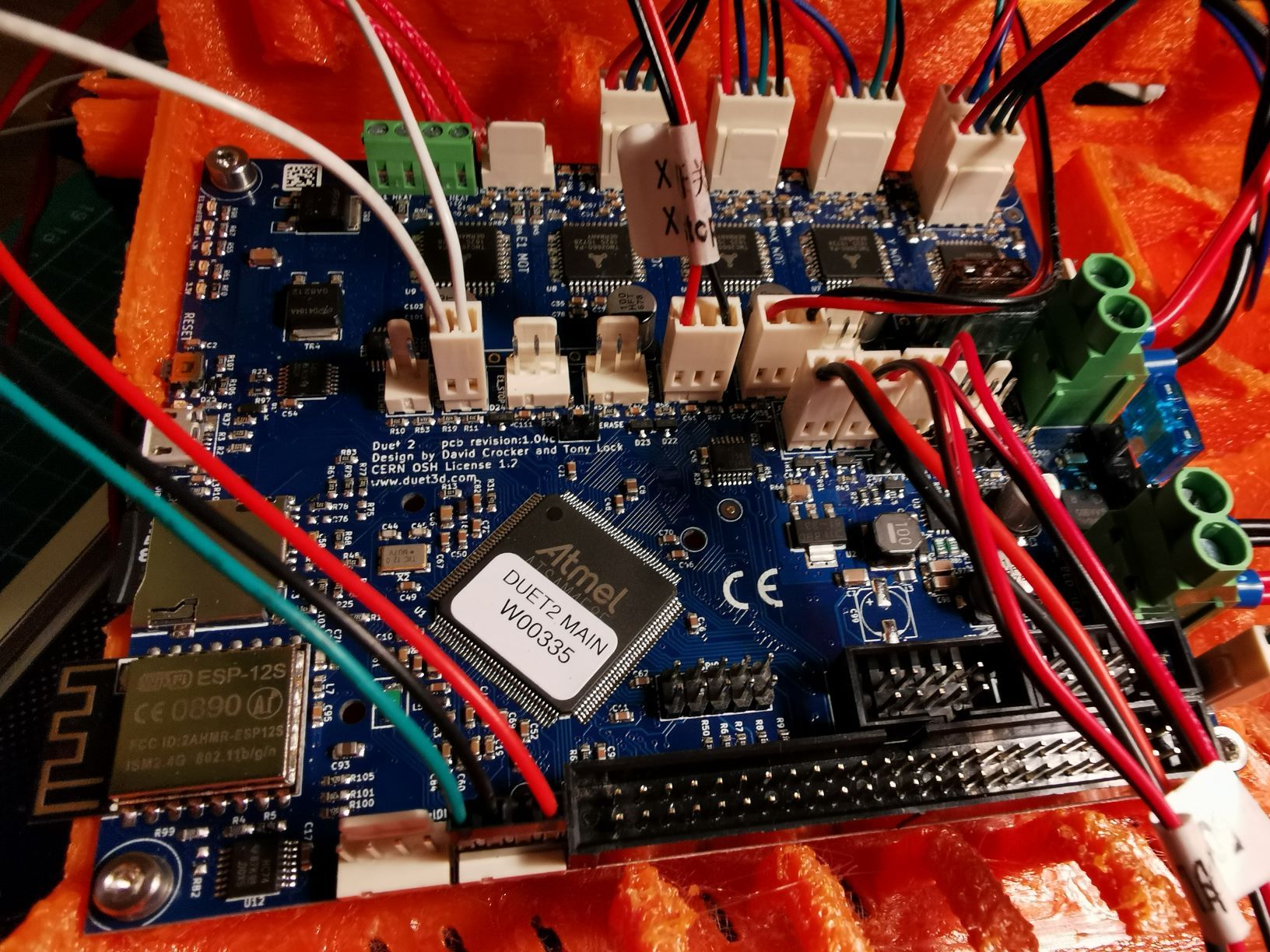

Can you post your config.g and homeall.g file? It sounds like there is an error somewhere. Please also take a picture of your Duet so we can see how wires are connected. Finally, send M115 to the Duet and post the response. This should give us the information to help diagnose the problem.

Be aware that you should ALWAYS turn off the power to your Duet board before plugging or unplugging motors into the stepper driver pins. If you don't do this, you risk damaging the stepper driver chip. Which you may already have done.

Ian

-

Note that an axis will not move until homed. For testing, you can override this with

M564 H0

-

@droftarts Yes I know about the spelling, but it´s often used and so I didn´t try. And of course the importance of turning of the board, so I hope the stepper driver are intact...

here is my config:

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.2 on Sat Nov 23 2019 01:39:28 GMT+0100 (Mitteleuropäische Normalzeit); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Anet A8" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

M575 P1 B57600 S1 ; Set auxiliary serial port baud rate and require checksum (for PanelDue); Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M569 P4 S0 ; physical drive 4 goes backwards

M584 X0 Y4 Z2 E3 ; two Z motors connected to driver outputs Z

M671 X-85:295 Y0:0 S2 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E99.5 ; set steps per mm

M566 X3000.00 Y3000.00 Z1000.00 E3000.00 ; set maximum instantaneous speed changes (mm/min)

M203 X3000.00 Y3000.00 Z1000.00 E3000.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z500.00 E500.00 ; set accelerations (mm/s^2)

M906 X700 Y900 Z700 E700 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y-5 Z0 S1 ; set axis minima

M208 X208 Y225 Z285 S0 ; set axis maxima; Endstops

M574 X1 Y1 S0 ; set active low and disabled endstops

M574 Z1 S2 ; Set endstops controlled by probe (Z-endstop is Z-probe); Z-Probe

M558 P8 x0 y0 z1 I1 H2 R0.75 F150 T3000. ; Set Z probe type to switch and the dive height + speeds

G31 P250 X0 Y0 Z0 ; set threshold and offsets

M557 X0:200 Y0:200 S40 ; Define mesh grid; Heaters

M307 H1 A450.6 C132.0 D5.5 V12.4 B0 ; disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S275 ; set temperature limit for heater 1 to 275C; Fans

M106 P0 T65:125 I0 H1:2 S0.75 C"Mitte" ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S0 I0 F500 H-1 C"Rechts" ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P2 S0 I0 F500 H-1 C"Links" ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off; Tools

M563 P0 D0 H1 F1:2 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

M501; Miscellaneous

M375 ; load height map

T0 ; select first tool -

@droftarts and here is my homeall.g

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v2.1.2 on Sat Nov 23 2019 01:39:28 GMT+0100 (Mitteleuropäische Normalzeit)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-244 Y-215 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F6000 ; go back a few mm

G1 H1 X-10 Y-10 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90

G1 H2 X100 Y100 F6000 ; go back

G30

;G1 H1 Z-265 F360 ; move Z down stopping at the endstop

;G90 ; absolute positioning

;G92 Z0 ; set Z to axis minimum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 S2 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning -

-

@Danal so I´ve tested to override the homing. then sent g0 for x-axis. For positive values, the motor hasn´t moved and blocked immediately. With negative value, it moved once and then blocked, too.

-

by the way, the board operated correctly all the time. A day before the first fault it printed correctly. At next day I powered it on, tried to home all. the x and y axis homed correctly and when it had to move to the middle of the heat bed nothing happened

-

raise your motor currents in M906. Maybe 1500.

-

@Danal did it and nothing changed, except the motor is humming little bit louder. 1,5A is the limit for this motor I think. It´s a 42SHDC3025-24B

-

@GuybrushTreepwood

measure the resistance of the motor for each phase. if the motor is humming its recieving current. -

@Veti I´ve measured the resistance now. it starts with 5 MΩ on green, black and goes up to over 30MΩ.

the blue/red coil starts with 12MΩ and goes up to 20MΩ.