Stop Print random. I not understand M122. Desperate

-

But i not configure nothing about x16 or interpolation because i have All axis's in external stepper drivers...

My steps are: X83.5 Y83.5 Z320 and E550 -

@FBG said in Stop Print random. I not understand M122. Desperate:

13926974

Can you post your config and some details about your setup?

-

@FBG said in Stop Print random. I not understand M122. Desperate:

But i not configure nothing about x16 or interpolation because i have All axis's in external stepper drivers...

My steps are: X83.5 Y83.5 Z320 and E550Hiccups occur when the time it takes to generate each step becomes larger than the interval between steps, so something has to give. So you need to either reduce the time it takes to generate each step by reducing the T parameters on your M569 commands for the external drivers (if you can do that without losing steps), or reduce the maximum speed to increase the interval between steps.

-

Today i reduce the steps of Extruder from 550 to 110.

I check the Hiccups a lot times with the same GCode and i see 11 hiccups a times, and another times 0 (mostly). I never see hiccups more that 13 or 14.

The printed work perfectly now.

I understand that hiccups 13 or 14 are stupid and not important yes?Thanks a lot

-

@FBG said in Stop Print random. I not understand M122. Desperate:

I understand that hiccups 13 or 14 are stupid and not important yes?

If that's 13 or 14 hiccups in a short move, it's too much. If it's in a long move at maximum speed with several motors moving at once, then it's OK although zero would be preferable.

-

I see this with all axis in movement, X Y Z and E, +compensate auto level, in not maximum speed but yes high speed.

-

@FBG said in Stop Print random. I not understand M122. Desperate:

I see this with all axis in movement, X Y Z and E, +compensate auto level, in not maximum speed but yes high speed.

High speed is hard to d when using external drivers, because of the long step pulses they need. What M569 T parameters are you using, and what timing does the driver manual specify?

-

I config 10:10:10:10

Manual steppers say: 2.5:5:5:0

-

@FBG said in Stop Print random. I not understand M122. Desperate:

I config 10:10:10:10

Manual steppers say: 2.5:5:5:0

10:10:10:10 is very high. For most drivers, 2.5 is sufficient for the first two values. The last two values may need to be a little larger, such as both 5.

-

So i will test 5 tomorrow, but i remember check 5 in the last and that stepper motor lose some steps.

-

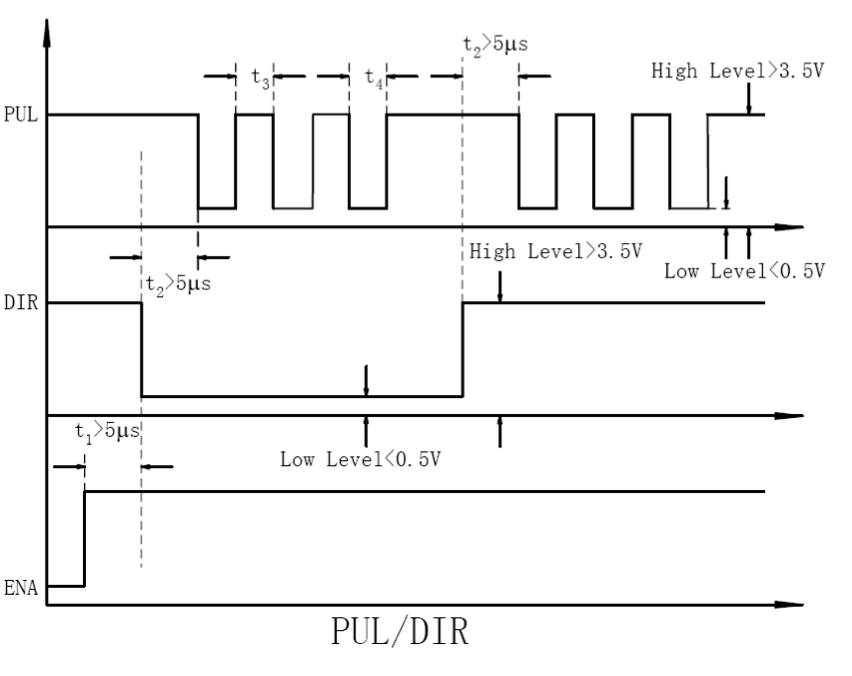

Follow the diagram the correct must be:

M569 T2.5:2.5:5:5yes?

Explain in manual:Remark: a) t1: ENA must be ahead of DIR by at least 5s. Usually, ENA+ and ENA- are NC (not connected). See “Connector P1 Configurations” for more information. b) t2: DIR must be ahead of PUL effective edge by 5s to ensure correct direction; c) t3: Pulse width not less than 2.5s; d) t4: Low level width not less than 2.5s.Thanks!