Rolling Magnet Sensor - 2.85mm Conversion

-

Hi All

Hardware:

- Duet 2 Wifi

- Titan Aero w/ 1.0mm E3D Nozzle X

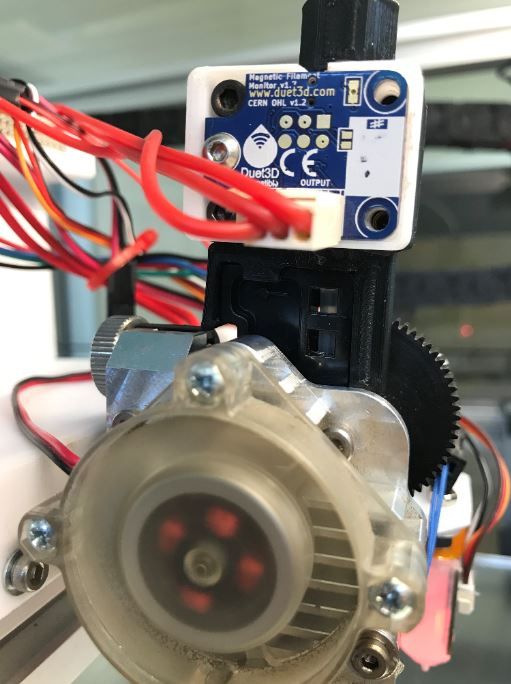

- Rolling Sensor Rev 1.7 - Mounted to filament pressure lever (picture below)

We have recently purchased a Duet Rolling Magnet Sensor for the intention to use it with 2.85mm filament, mostly 85A Ninjaflex. We have successfully reverse engineered the 1.75mm housing and adapted it to fit the larger filament.

After successfully connecting the sensor to our Duet 2, we have began to receive readings while running test prints which are less than ideal, min 87%, max 113% over 581.2mm, and are hoping to improve upon this. My thinking is that the sensor is trying to measure filament retractions which isn't read accurately with the flexible filament(?). I have calibrated the sensor as accurately as possible.

Has anyone successfully adapted the 1.75mm sensor to fit 2.85mm filament?Thanks for all of help.

-

@BenNorton01 Please post your config.g, or at least the part for the setup of the magnetic sensor. You should be able to set it to ignore retractions (it's the default), using the 'A' parameter of M591. See https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M591_Configure_filament_sensing

Have you changed the hobbing on the hobbed assembly? I don't have my one to hand, but I'd think that the hobbed channel is too narrow for 2.85mm filament, so it's just riding on the shoulders of the hobbing, rather than sitting firmly in the groove. This may cause it to slip.

Ian

-

You may wish to increase the sample interval from the default 3mm.

-

Hello Droftarts and DC42

Apologies for the long reply. I was not receiving notifications from these posts as I used to and did not see your replies.

; Filament Sensor ; M591 D0 P3 C4 S1 R80:120 L26.32 E3.0 ; filament sensor for extruder 0, enabled, sensitivity 26.32mm.rev, 80% to 120% tolerance, 3mm detection lengthI have not had time to play with the setup any further but from the looks of things, the filament is nicely held in the hobbed groove. I may re-print the housing with our Form 2 SLA printer and see if that helps with the alignment of the idle wheel.

Kind Regards

Benjamin Norton