Gcode for moving just one extruder motor in a mixing extruder ?

-

I hope this is a simple question.

I have a dual tool syringe printer for clay in which each tool is a mixing extruder.

When changing tools I would like to "prime" the extruder by advancing one of the tool's motors a small amount but not the other.

I know how to tell the tool to do a small "prime" extrusion, but this does so as a "mix", which in my unique setup actually creates ooze.

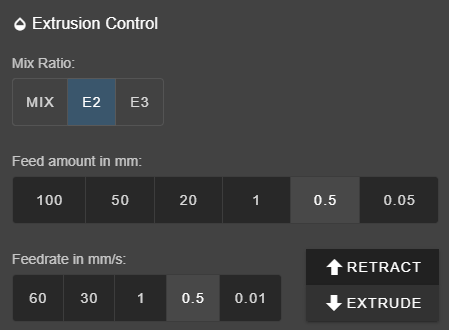

I need to duplicate what I can do manually in the web interface control panel in the picture below:

I guess another way to ask this is: Is there a way to see the gcode output from commands one executes in the web interface?

-

@tom_lauerman Hmmm - I understand your problem. You can do a sort of G1 Enn Dnn from the web interface where Dnn is the particular extruder. I'm not sure if there is a single gode command that can do this. Maybe someone more knowledgeable than I can help. In the meantime, a possible work around would be to use a macro which would firstly re define the tool to use just one extruder, do the extrude, then re-define the tool back to using both. Or possibly keep the tool definition the same but change the mixing ratio at the start of the macro to use 100% of a single extruder, then set the mixing ratio back to "normal" at the end of the macro.

-

Many thanks @deckingman . I neglected to mention that this action should happen within the "tpost.g" file in the system files. My assumption is that this could function exactly like a macro.

I'll give your suggestion here a try. Many thanks again.

-

@tom_lauerman Yes tpost.g is a macro. So you could do the tool re-defining or mixing ratio change within that file.

-

@deckingman excellent, thanks for confirming this.

-

@tom_lauerman Although that should work, I should also like to know what commands DWC sends when extruding filament from one of the extruders used by a mixing tool.

-

If you have defined the tool to use 2 drives, you can use GCode commands of the form G1 Exxx:yyy (with or without XY movement too) to specify amounts to extrude from each extruder. If you specify just one E value then it takes that as the total and uses the mix ratio.

-

@dc42 Ahh. So to be clear, if I had say a 5 extruder mixing hot end and I wanted to extrude an amount of filament (nn) using drives 1 and 3, I would use the format G1 E0.0:nn:0.0:nn:0.0. yes? (assuming the 5 drives are 0 to 4). I assume that would extrude nn from each extruder giving a total of nn*2 and so with my 5 input mixing hot end, if wanted to extrude a total of nn, then I'd use the same format but specify nn as being nn/2 for each individual extruder yes? Lastly, the firmware takes care of each extruder speed so the feedrate through the nozzle would be as specified but for two extruders in would 50% for each yes?

And so all @tom_lauerman needs to do is G1 Enn:0.0 (or E0.0:nn) yes?

-

@deckingman @dc42 Thank you for these insights! I'll get to work on this.

-

@deckingman said in Gcode for moving just one extruder motor in a mixing extruder ?:

@dc42 Ahh. So to be clear, if I had say a 5 extruder mixing hot end and I wanted to extrude an amount of filament (nn) using drives 1 and 3, I would use the format G1 E0.0:nn:0.0:nn:0.0. yes? (assuming the 5 drives are 0 to 4). I assume that would extrude nn from each extruder giving a total of nn*2 and so with my 5 input mixing hot end, if wanted to extrude a total of nn, then I'd use the same format but specify nn as being nn/2 for each individual extruder yes?

And so all @tom_lauerman needs to do is G1 Enn:0.0 (or E0.0:nn) yes?

Yes. You can either provide one E parameter per extruder, or just one.

Lastly, the firmware takes care of each extruder speed so the feedrate through the nozzle would be as specified but for two extruders in would 50% for each yes?

To be honest, I can't remember how the speed is calculated for extruder-only moves when you specify more than one E parameter

-

@dc42 said in Gcode for moving just one extruder motor in a mixing extruder ?:

Lastly, the firmware takes care of each extruder speed so the feedrate through the nozzle would be as specified but for two extruders in would 50% for each yes?

To be honest, I can't remember how the speed is calculated for extruder-only moves when you specify more than one E parameter

OK, no worries. I'll try it when I get time and see what happens. It certainly maintains the correct nozzle feedrate when selecting multiple extruders via DWC (by slowing down each individual extruder) but that might be something that Chris Ham has done, rather than RRF firmware.

-

Thanks for your help with this, I was able to implement it exactly as I had hoped to, and was able to play around with different feed rates using F, and was able to match within a macro the length and speed of extrusion I had been using "manually" on the web control interface.

Thanks again!

-

@tom_lauerman No worries. Glad you got sorted (and I learned something along the way too)