Is there a basic guide to set the duet up as a CNC

-

Ok so am I right in saying :

- I have a gcode file (just a re-named .nc file from fusion 360)

- I home my machine using g28.

- I jog the machine to the start of the file gcode

- Use G10 L20 P2 X0 Y0 Z0 To set the co-ords for the start of the file.

- then run the file?

How do I ensure the file runs using the work co-ords and not the machine co-ords? Do I need to specify it at the start of the file?

-

@Asdasd1234 said in Is there a basic guide to set the duet up as a CNC:

How do I ensure the file runs using the work co-ords and not the machine co-ords? Do I need to specify it at the start of the file?

Think there is an option in your post processor to either run G28 or G54 at the start of the exported g-code? Been awhile since I've messed with that stuff. You can review the top of the exported g-code to verify what you get.

-

@Asdasd1234 said in Is there a basic guide to set the duet up as a CNC:

How do I ensure the file runs using the work co-ords

All CNC machines that follow G-Code standards are always in a work coordinate system.* The default at power up is G54. When you do the G10 L20 P2, you are setting the "second" system, namely G55.

Therefore, you can have a G55 at the very start of your file, or issue a G55 via the Web interface.

* Always, with the single exception of an individual line that starts with G53, which will operate in machine coordinates. G53 is not 'sticky' and therefore applies to only the line where it appears.

-

@Danal

Ah, so I could do the following?- G28 home the machine

- Jog machine to start of file.

- Run macro that does:

-G10 L20 P2 X0 Y0 Z0

-G55 - Then run the file?

Sorry for all the questions, I just realllly dont want to crash the machine into an axis or the bed etc

-

@Asdasd1234 said in Is there a basic guide to set the duet up as a CNC:

Ok so am I right in saying :

- I have a gcode file (just a re-named .nc file from fusion 360)

- I home my machine using g28.

- I jog the machine to the start of the file gcode

- Use G10 L20 P2 X0 Y0 Z0 To set the co-ords for the start of the file.

- then run the file?

How do I ensure the file runs using the work co-ords and not the machine co-ords? Do I need to specify it at the start of the file?

You are basically correct, here is a slight rephrasing of a couple of lines, just for clarity.

- I have a gcode file (just a re-named .nc file from fusion 360) Correct, upload that file via the Web interface

- I home my machine using g28. Correct

- I jog the machine to the

start of the file gcodeto the tip of the cutter just touching the origin of the stock. Normally in the 'lower left' corner, and just touching top-of-stock in Z. - Use G10 L20 P2 X0 Y0 Z0 To set the co-ords for the

start of the file.the second work-coordinate-system (G55) to match the physical object I want to cut - then run the file? Issue a G55, then, Yes, in the Jobs tab, click then file, then OK

-

@Asdasd1234 said in Is there a basic guide to set the duet up as a CNC:

G28 home the machine

Jog machine to start of file.

Run macro that does:

-G10 L20 P2 X0 Y0 Z0

-G55

Then run the file?Yes

-

@Danal

Thats great, I'll try that now. Thanks a bunch for the help people. Its much appreciated -

No problem.

This does assume you've set Z0 to top of stock in Fusion. This is a fairly normal CNC practice.

-

@Danal

I'm pretty sure I have, but will double check -

Ah, I might have an issue.

F360, when set to grbl only lists out the co-ordinates and doesn't do a G1/0 before them like:

G1 Z1 F500 Z-1.999 Y26.033 Z-2 F1200 Y26.034 X28.967 Y26.035 X28.595 Y26.047 X28.194 Y26.057 X27.792 Y26.067Will this still work?

-

No. Duet doesn't support "sticky" G1 or G0. You will need to select a different post processor, or modify that one.

-

I use Mach3 post. Which isn't perfect, but it does put G1 on each line.

-

i found a post processor online for duet. I need to manually delete out the G54 at the start, but my test pen-plot has come out perfect. Thanks a bunch!

-

@Asdasd1234 said in Is there a basic guide to set the duet up as a CNC:

I have a gcode file (just a re-named .nc file from fusion 360)

you can edit the .cps file and change the line that says (line 28 in the grbl if thats what you used)

extension = "nc";

to say

extension = "gcode";

to not have to do the renaming.@Asdasd1234 said in Is there a basic guide to set the duet up as a CNC:

I need to manually delete out the G54 at the start

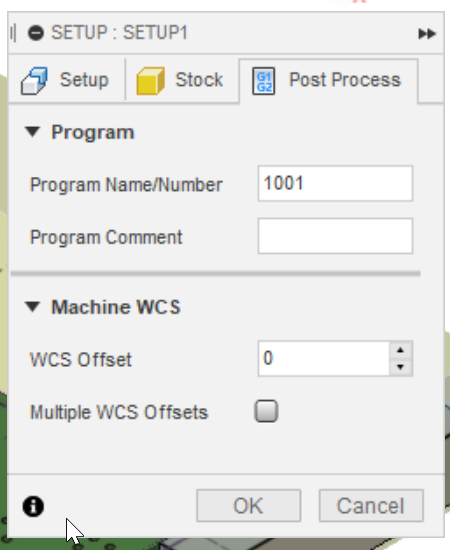

try putting a "2" in WCS offset here if you wanted G55 instead.

Setup -> Post process tab:

(edit: or you could edit the file and change 1 to 2 in line 353 to make it permament and not have to set it each time.)

((or search forvar workOffset = currentSection.workOffset;and changeworkOffset = 1;toworkOffset = 2;a few lines below if your post is different from the grbl))

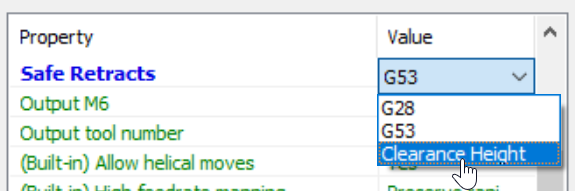

(((or if you just wanted to get rid of the whole G54 thing try changeing the Safe retracts parameter in the post to ClearanceHeight

)))

))) -

@Danal said in Is there a basic guide to set the duet up as a CNC:

No. Duet doesn't support "sticky" G1 or G0. You will need to select a different post processor, or modify that one.

Yes it does, when in CNC mode and using recent firmware versions (2.05 or 3.x).

-

@bearer said in Is there a basic guide to set the duet up as a CNC:

you can edit the .cps file and change the line that says (line 28 in the grbl if thats what you used)

extension = "nc";

to say

extension = "gcode";

to not have to do the renaming.You don't have to rename anyway. DWC and RRF accept .nc files.

-

@Asdasd1234 said in Is there a basic guide to set the duet up as a CNC:

Run macro that does:

-G10 L20 P2 X0 Y0 Z0

-G55Alternatively, use P1 in the G10 command instead of P2, then you don't need the G55.

-

@dc42 said in Is there a basic guide to set the duet up as a CNC:

@Danal said in Is there a basic guide to set the duet up as a CNC:

No. Duet doesn't support "sticky" G1 or G0. You will need to select a different post processor, or modify that one.

Yes it does, when in CNC mode and using recent firmware versions (2.05 or 3.x).

Ah... I tried it, but not in CNC mode... grasshopper learns from master once again.

-

@dc42 said in Is there a basic guide to set the duet up as a CNC:

@Asdasd1234 said in Is there a basic guide to set the duet up as a CNC:

Run macro that does:

-G10 L20 P2 X0 Y0 Z0

-G55Alternatively, use P1 in the G10 command instead of P2, then you don't need the G55.

This is true... but... a lot of people like to leave G54 matching machine, because there the controller is always in some Work Coordinate System, and it just makes more sense for the human to have G54 match the physical layout of the device, G55 match the first fixture, G56 the second fixture and so forth.

Again, there is no "right or wrong" here... and some people do it a completely different way... the most common practice I've seen is leaving G54 alone (or, technically, G54 has a 0,0,0 offset to G53).