Piezo20 probe and piezo kit now available

-

; Configuration file for Duet WiFi (firmware version 1.17)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Sat Feb 04 2017 22:32:57 GMT+0000 (GMT Standard Time); General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates…

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X230 Y230 Z200 S0 ; Set axis maxima; Endstops

M574 X1 Y1 Z0 S0 ; Define active low and unused microswitches

M558 P1 I1 F500 X0 Y0 Z0 ;analogue piezo sensor output falls on contact, probing speed, not used to home axes

G31 X0 Y0 Z0.03 P700 ;sensor is nozzle and trigger value; Drives

M569 P0 S0 ; Drive 0 goes backwards

M569 P1 S0 ; Drive 1 goes backwards

M569 P2 S0 ; Drive 2 goes backwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.5 Y80.5 Z405.9 E455.9 ; Set steps per mm

M566 X900 Y900 Z12 E120 ; Set maximum instantaneous speed changes (mm/min)

M203 X8000 Y8000 Z180 E2200 ; Set maximum speeds (mm/min)

M201 X800 Y800 Z250 E800 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z800 E1000 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Heaters

M143 S260 ; Set maximum heater temperature to 260C

M305 P0 R4700 T100000 B3950; Set thermistor + ADC parameters for heater 0

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Network

M550 PPhytone ; Set machine name

M552 P0.0.0.0 S1 ; Enable network and acquire dynamic address via DHCP; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Custom settings are not configured

-

RepRapFirmware height map file v1, mean error -0.20, deviation 0.04

xmin,xmax,ymin,ymax,radius,spacing,xnum,ynum

60.00,240.00,35.00,220.00,-1.00,40.00,5,5

-0.119, -0.143, -0.094, -0.183, -0.207

-0.205, -0.220, -0.178, -0.092, -0.198

-0.215, -0.205, -0.237, -0.244, -0.173

-0.242, -0.230, -0.210, -0.225, -0.225

-0.230, -0.190, -0.188, -0.156, -0.274 -

and this is the start of a g-code file

;FLAVOR:RepRap

;TIME:2049

;Filament used: 3.66315m

;Layer height: 0.3

;Generated with Cura_SteamEngine 2.4.0

M190 S70

M104 S190

M109 S190

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z1.0 F9000 ;move the platform down 1mm

G92 E0 ;zero the extruded length

G1 F200 E3 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length again

G1 F9000

M117 Printing…

;LAYER_COUNT:83

;LAYER:0

M107

G1 F1800 E-4

G0 F3600 X102.801 Y104.451 Z0.3

;TYPE:SUPPORT

G1 F1800 E0

G1 X137.199 Y104.451 E1.63032

G1 X137.199 Y135.549 E3.10423

G1 X102.801 Y135.549 E4.73455

G1 X102.801 Y104.451 E6.20846

G1 F1800 E2.20846

G0 F3600 X113.873 Y114.036

G0 X113.955 Y114.11

G1 F1800 E6.20846 -

adding G31 Z-0.2 or G31 Z0.2

or extremes like G31 Z-4 or G31 Z 4into the config.g file has NO impact whatsoever.

I'm stumped.

-

I've only skimmed this a bit tied up, but do you need the H2's in your bed. G?

Edit Yes I suppose you do, I haven't used RRF on a cartesian machine. Hmmm…

Not exactly on topic but have you tried the probe on digital instead of analogue, with low debounce value? You can probe at a higher speed with no false triggers.

I posted my M558 and G31 on a previous page.

-

Wow, a world of difference using this probe after a couple of minutes setting up:

…This is what I got with DC42's sensor AFTER spraying my aluminium heat bed with black matt paint and probing my Printbite (the sticky tape makes it a bit patchy as in the photo - is this causing the problem?):Yes, the variable reflection from the sticky tape is the problem. With PEI you have to spray paint the back of the PEI matt black, cure it in an oven, then stick it painted side down to the bed plate. I imagine PrintBite is similar.

I can confirm I had issues with print bite and IR sensor when the PB was mounted directly on aluminium plate

-

I've only skimmed this a bit tied up, but do you need the H2's in your bed. G?

Edit Yes I suppose you do, I haven't used RRF on a cartesian machine. Hmmm…

Not exactly on topic but have you tried the probe on digital instead of analogue, with low debounce value? You can probe at a higher speed with no false triggers.

I posted my M558 and G31 on a previous page.

I removed the H2 and the auto bed compensation graph was higher, but still under z0. Did a probe, which still showed as also under the bed, went to print and the print head wants to start at somewhere around z-5.

Had enough for today. Will try digital tomorow.

-

I've been thinking about effector mounting of piezo sensors as opposed to the under bed sensors that I'm using at the moment, here's what I've come up with.

For a long time now I've been mounting my hot end so that the nozzle is as close in height to the arm mounting as possible. I've been doing this for a couple of reasons:

I hate losing build height, I regularly print things that scrape the top of my Kossel Minis 230mm build height, with an underslung hot end I'd probably lose 50mm or more.

I think that a smaller distance between the arms and the nozzle will minimize effector tilt.

With that in mind, here is the first prototype of my integrated piezo effector.

I've soldered brass M3 nuts to the back of the piezo disks which avoids having to drill holes in them. Unfortunately I can't test this on my printer at the moment, my printer is set up with metal balls on the arms and cups on the carriages and effector, I need to swap them around but I'm waiting on more steel balls.

Idris

-

Its amazing what a day away does…

Nozzle diving below print bed - problem solved.....

Given it was probing nicely, turned my attention to the G-CODE file.

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 F6000 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstopsRemoving the G28 Z0 from the code seems to fix it, and it prints at the right height. Now I need to figure out why......

-

What are you using as your z_min endstop? Is it the piezo probe or do you have a mechanical endstop also?

-

It's the probe…...

-

probably makes no difference but why home xy and then z?

Why not just do G28?

You don't need the X0 Y0 coordinates.I doubt thats it but worth a try, also I'd do your Z home at bed centre so maybe

G28 XY F6000

G1 Xx Yy F6000

G28 Z -

New Piezo Z-probe boards are in as well as Piezo Endstop boards if anyone wants to give those a try.

Idris

-

These piezo's are tough units (using 27mm). In fiddling around, the + wire became detached from the centre (pulled the white stuff off)- thought I'd reattach/solder and hope. Well works fine!

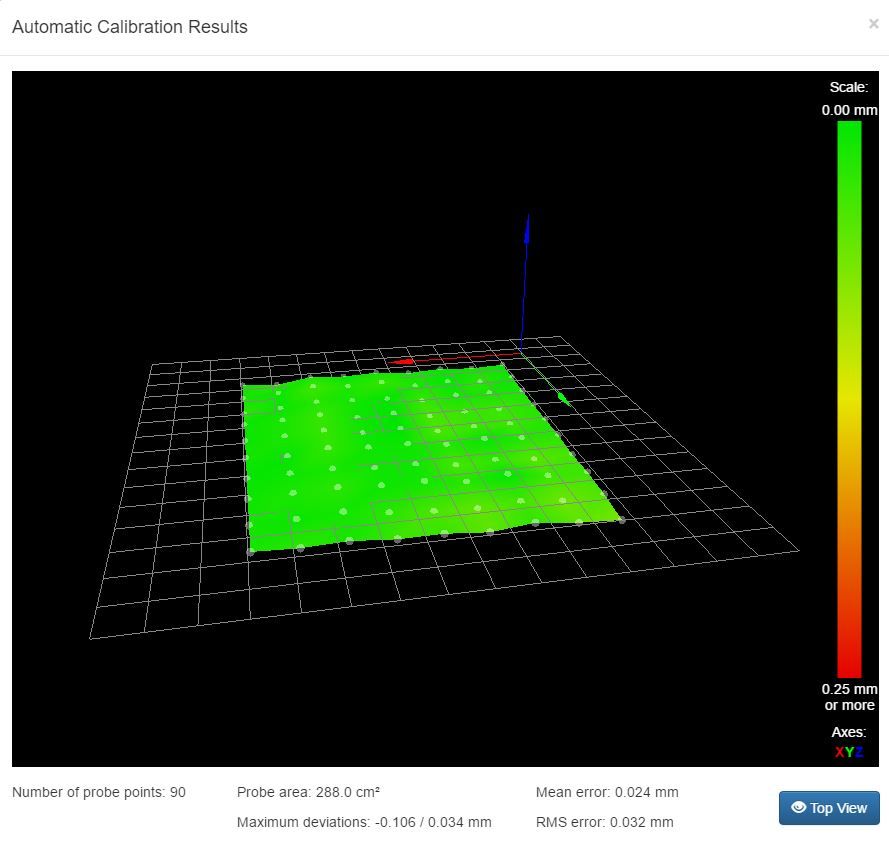

After some more meddling, I am now getting really good results.

This is the best bed mapping that I've ever had on the printer since running duet wifi.

-

Excellent results that's very satisfying.

Yeah they are quite tough the piezo's. On my test rig I've slammed it into the test bed so hard and so many times, it broke the bracket holding the module, but the piezo was still working like a champ. I've had a few de-soldered wires but soldered them back on with little or no drama. One of the issues moving this forward into a consumer unit is the fragility of the soldered connections on the piezo. My thinking is integrate the control board into the sensor module, thereby reducing the mobility in these wires to zero. It also reduces the (theoretical at this point) risk of interference on the lead to the piezo causing issues. There is another idea involving making the piezo part of the circuit and placing that in between the two parts of the assembly.

-

Talked to a few people at MRRF and handed out some piezo's to a couple guys who had ideas about how to cut the holes more precisely, without any damage. Hopefully I'll have more info on their results soon.

-

That sounds great. Mike (Leadinglights) has developed a method of cutting them on a lathe. Reasonably neat cuts too. That being said none of the discs I have drilled have failed to perform initially or since.

I hope at some point we can source or have made piezo's with holes in at manufacture.

-

Okay so Idris and I are getting closer to having a drop in module ready. More or less settled on the design, just a bit of tweaking. It's done several thousand probes on the rig with no issues. Very stiff as it turns out you don't need any noticeable vertical compliance to get a trigger. Idris is making a custom pcb for it.

Should be a case of remove hot end, insert module between hot end and extruder/carriage and then plug in your endstop wire. It's for groove mount but could be easily adapted with a few bolt holes for screw mounting.

It's small around 30x20x18mm. Should illuminate on trigger (but will also make a solid colour version also).

Aiming for around £25 delivered (UK) for final version. The initial units will be considered beta units and be £19.99 delivered (UK) on the assumption we will get some feedback on improving the product.

International postage will be by individual postage quote.

-

So this would be a piezo with a hole for a bowden, and you just drop it over the top of your groovemount (around the bowden)?

-

So the idea is this is a module which will sit between the groovemount in your effector/carriage/extruder such as a titan, and your hotend. It will have just a 3 wire endstop connector on it. Its pretuned and tested on my rig. If you are using one in a chamber or your ambient temp is 35 deg C+ then let us know we will tune one for higher temp environment, or leave the PCB adjuster with no threadlock on it so you can tune it yourself.

If using bowden, you'd just feed your bowden tube through the middle, there will be space to attach and tension the bowden tube on the hot end, as well as remove the hot end without dismantling the module. If using direct I will supply a short length of bowden tube to use as a filament guide from extruder down into the hotend.

This is what it looks like in my test rig. If you don't want groovemount I'll do a version with captive nuts and bolt holes for direct mounting to underside of a carriage or effector. Almost no compliance of the nozzle in this design, the piezo is pre-tensioned quite firmly.

The new custom PCB will be attached to the back of the module for the transparent version and it will light up the module when powered and hopefully change colour when triggered. If preferred a solid colour version will also be available with the pcb on the front (you can insert the module into your printer whichever way around you want) so it will show two LED's one for power, one for triggered.

This module completed 2000 probes on the rig with no issues. I intend to do a test run of 36800 probes which will simulate a full year's use in a heavy-duty-cycle environment, based on doing 16 probes on a delta to autocalibrate each print, and doing 10 prints per day for 46 weeks per year, 5 days a week. This is likely to represent 3+ years of use in a slightly more normal environment.