Anet A8 Tuning Issues

-

Hello,

I am working on getting my printer all tuned up, and as of right now I have all my steps calibrated. I am trying to work out two bugs right now:-

ghosting

-

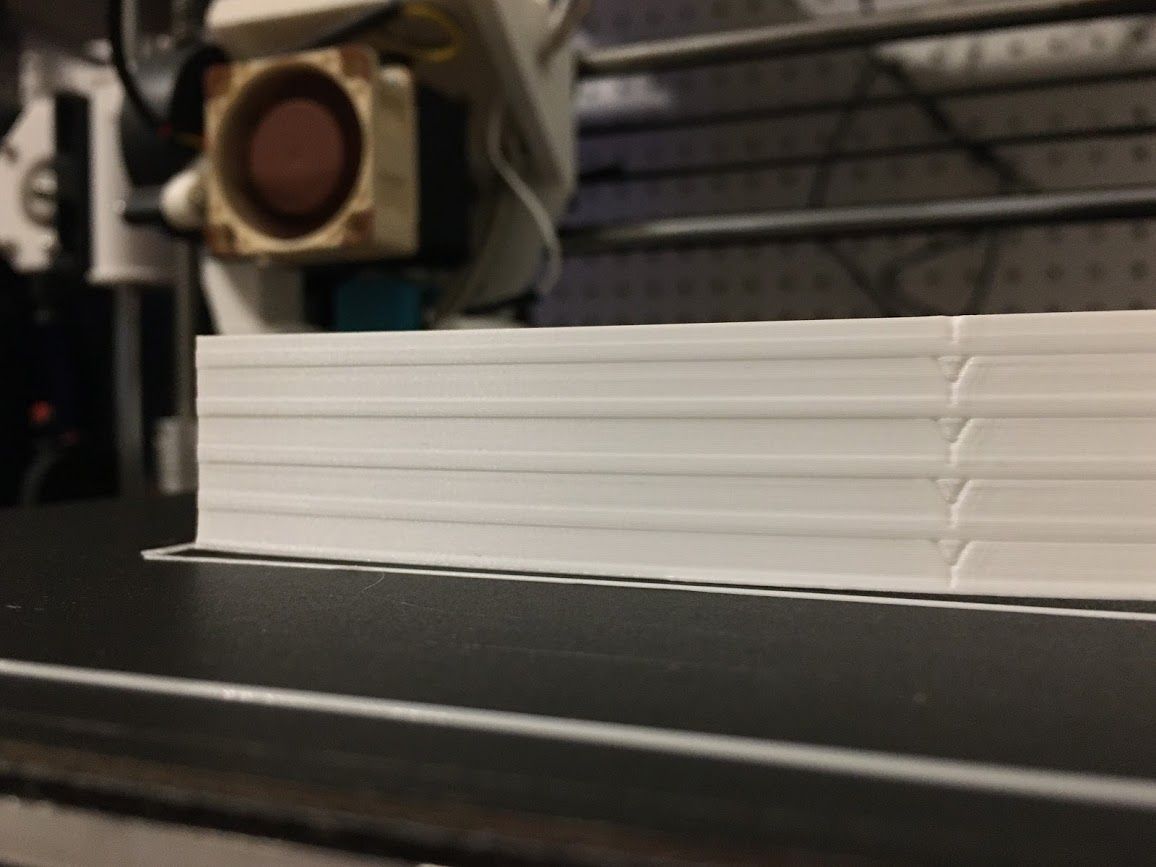

intermittent extrusion problems. As seen in the pictures below, and just so we are all on the same page, this part was a ghosting test print. that being said the "X" and the "Y" are not the actual X and Y axis.

-

-

@anetA8Duet Ghosting is related to 'ringing' in your machine. This can be the frame moving, or belts vibrating/stretching, or other unwanted movement. It is related to speed and acceleration of movement. There is M593 ( https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M593_Configure_Dynamic_Acceleration_Adjustment ) that can be used to tune out some of this movement.

I wouldn't call that layer banding 'intermittent', I'd call it regular! As it's (mostly) in one axis direction, look to see if there's any play in the belt/pulley of the Y axis first. I don't think it's Z or extrusion related, or it would be more visible on the X side.

Ian

-

Now that you mention it, I do think my frame is moving. I am going to print out a brace like my other anet in the front and see if that calms it down a bit. I am just trying to by a little time till I can buy an all aluminum frame. thank you for the link on the acceleration adjustments. I might try and adjust some of those settings just a little.

-

I think that brace is what's helping. At the start of the print I had just a slight shift in layers, so I tightened the belt just a little more and it looks much better. Now I think I will start trying to figure out those acceleration settings. I'll let you know what I come up with. That is if anyone is interested in this.

-

@anetA8Duet 1000 on the acceleration is a good place to start, and 800 works well for me without loosing too much print time.

-

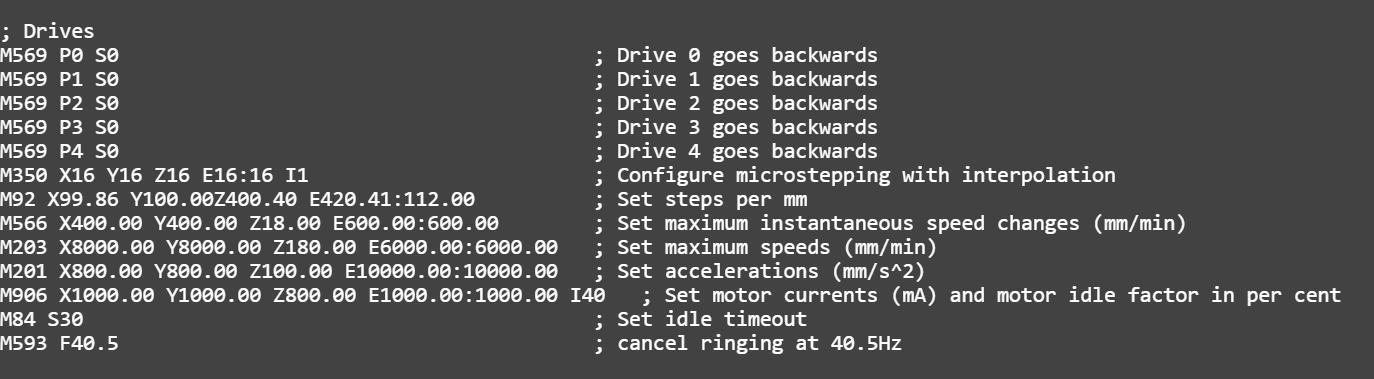

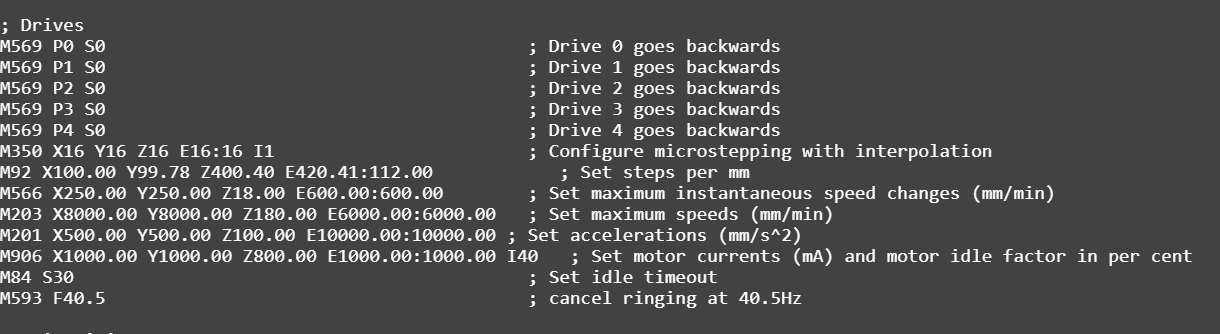

It's hard to tell, but I am still having some trouble. I think at this point it's just the frame. Here is a before and after snip from my config.

-

You can try using different values for X and Y. The weight of the bed (and any number of other differences between the X and Y axis) can require different acceleration and jerk values. Typically you can get away with more aggressive values on X than you can on Y.