Hi at this please help

-

Hi at this please help, I have a problem

how to set up cube printing

I have duet wifi 2

RepRap

-

Please post your config.g

It looks like extruder calibration in the first instance. Have you done that yet?

Regards,

Paul -

Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Fri Feb 21 2020 16:39:28 GMT+0100 (Mitteleuropäische Normalzeit); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Mister" ; set printer nameM667 S1 ; select CoreXY mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable TelnetM555 P1 ; Set firmware compatibility to look like Marlinxxxxxxxxxxxxx

; Drives

M569 P0 S0 ;E physical drive 0 goes forwards

M569 P1 S0 ;X physical drive 1 goes forwards

M569 P2 S1 ;Y physical drive 2 goes forwards

M569 P3 S1 ;Z physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I0 ; configure microstepping without interpolation

M92 X80 Y80 Z793.6 E98.03 ; set steps per mm

M566 X2000 Y2000 Z20 E1000 ; set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 Z600.00 E6000.00 ; set maximum speeds (mm/min)

M201 X800.00 Y800.00 Z200.00 E800.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S120 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X300 Y260 Z310.40 S0 ; set axis maxima; Endstops

M574 Z2 S0 P"zstop" ; configure active-high endstop for high end on Z via pin zstop

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"zprobe.in+zprobe.mod" H5 F400 T9000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z4.45 ; set Z probe trigger value, offset and trigger height

M557 X1:300 Y1:260 S60 ; define mesh grid; BED

M308 S0 P"bedtemp" Y"PT1000" X500 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M307 H0 A269.0 C392.3 D2.9 B0

M305 P0 T100000 X500 R4700

M140 H0 ; map heated bed to heater 0; HOTEND

M308 S1 P"e0temp" Y"PT1000"T100000 X501 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 B0 S1 ; disable bang-bang mode for heater and set PWM limit

M307 H1 A438.8 C250.7 D5.7 B0

M305 P1 T100000 X501 R4700; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H1 T100 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 F0:1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Miscellaneous

M911 S22 R23 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool -

@PaulHew said in Hi at this please help:

extruder calibration

Hello, thank you for helping me, extruder has been calibrated

-

extruder has been calibrated but the error remains despite what remains.

Thanks Eder -

So you have changed your M92 E value?

I would suggest that you go through this part of a superb guide.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165Make sure your E steps are correct, then print the calibration cube to tune you flow rate.

I would start with PLA filament before moving on to other filament types such as PET-G.Get the basics right first, I have been known to miss these crucial steps!

Have you upgraded recently?

-

This post is deleted! -

@eder said in Hi at this please help:

yes i have ok i try

-

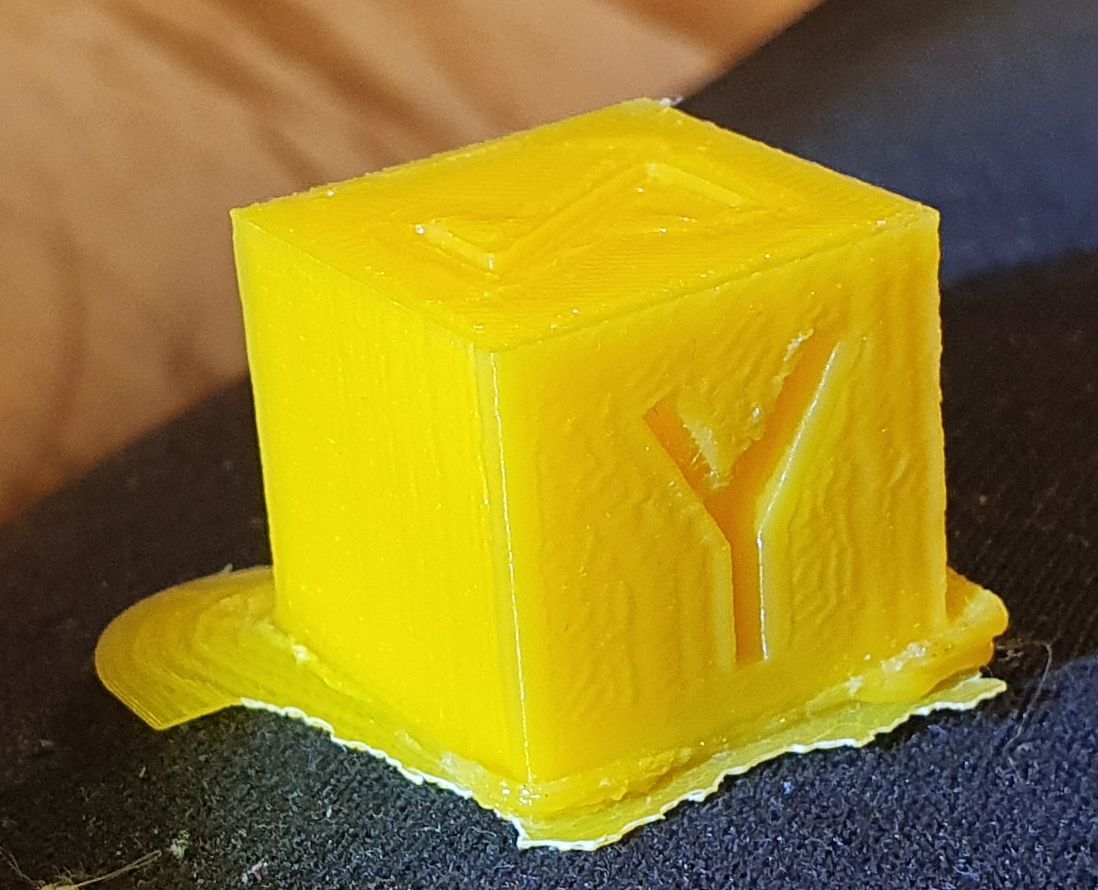

hello, has gotten better but the problem remains despite: - ((

-

Hi, I got similar problem with exactly same model to print

But in my case whole model prints very well except first layers corners and corners only were over extruded.

Since in your print it is in bottom and up layers, that might suggest that you could have a look on slicer settings for top/bottom check if you have some hidden settings in slicer and unhide them. Hope you find a clue.Regarding mine problem I wasn't even looking for that solution just because I have generally something very wrong with filament flow in my setup...

I remember seeing somewhere setting (or something) that has something to do with extrusion in slows down for cornering, but can't remember where. I'll post if I find.

-

This post is deleted! -

thanks monster for information i look times