Overextrusion at low Temps

-

Hey there, I have been struggling with a problem for the last 3 week or so where i get some sort of overextrusion printing at temps lower than 220 ° C which i think is quite hot for PLA (I usually Print at 195 ° C with good results) . I have tried almost everything. I have calibrated the extruder (E3D Titan with a V6 set up as an bowden setup with capricorn tubing) multiple times, changed accelerations, stepper current, retraction setting ...

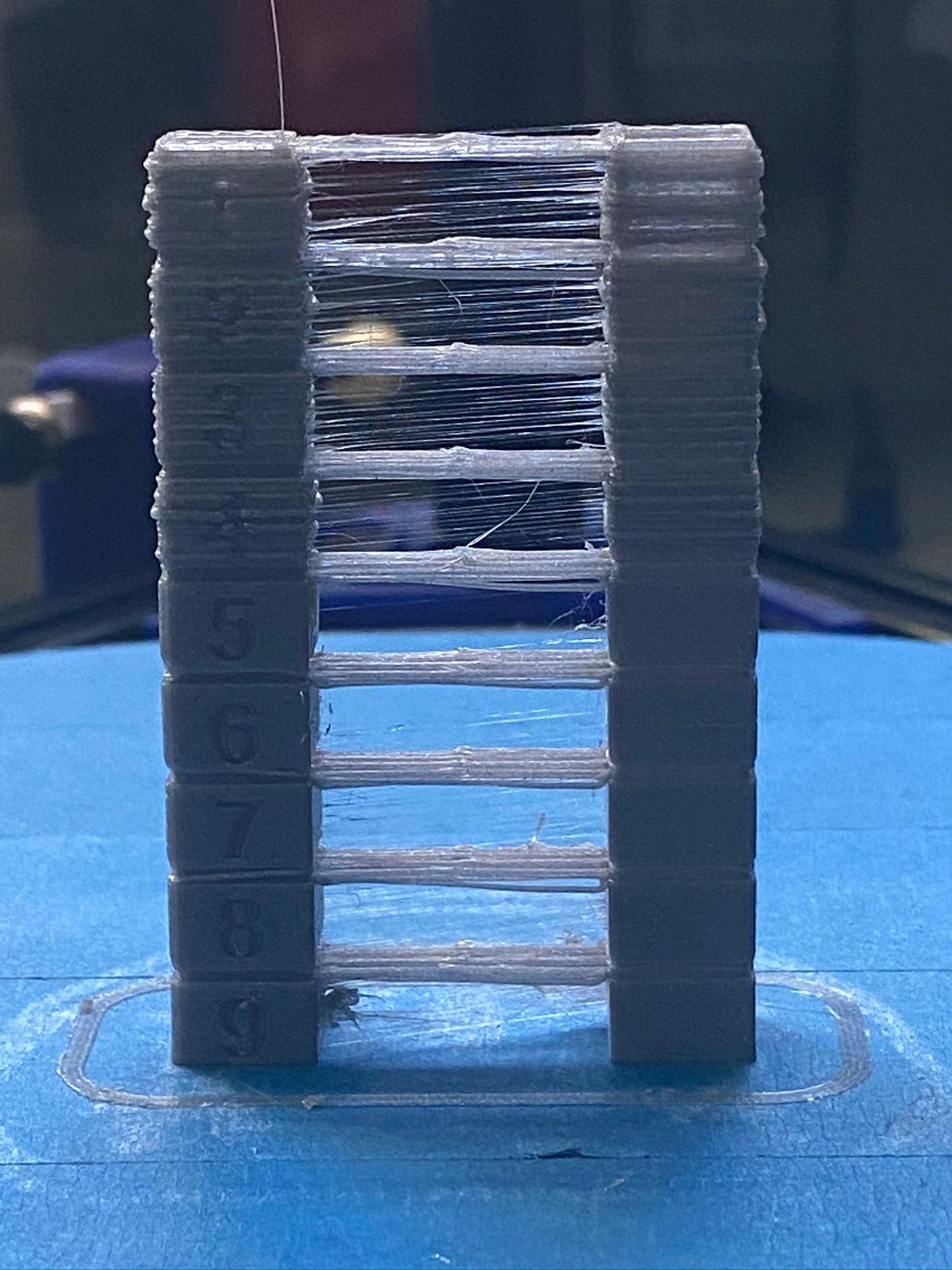

The picture shows a temp tower which was printed at these temps:

1 200

2 205

3 210

4 215

5 220

6 225

7 230

8 235

9 240

as you can see at 215°c I start getting Over Extrusions and i dont know what causes that because i always thought over extrusion is mainly caused by too High Temps.

If anybody has any idea on how to fix this i would greatly appreciate help -

This is effectively die swell as your polymer isn't hot enough to flow properly. Ultimately, its factors of your extrusion rate and the energy (heat) in the polymer as it exits the nozzle. The faster you print the fast you need to put energy into the filament to heat it to the core.

So you're either printing too fast, or your not getting enough energy in (effectively you're temperature is too low). If you're printing at a sensible speed, and you know your filament is good then either the measured temperature reading is wrong or the inside walls of the hot side of the heat-break or nozzle are dirty and aren't transferring energy efficiently. -

@ChrisP

Thanks for the fast response. I will to an another cold pull to make sure the nozzle and headbrake are clean. And than I will try printing slower at a temp were i usually got the problem to find out if this helps. But for my my usual seeds I will just use the last temp that worked in the temp tower. -

Are you using an E3D thermistor cartridge? Are you using the correct values for that thermistor? That will help ensure your temps are accurate to what you are setting. The displayed temp may not be correct, so go with what actually works in practice.

-

@Phaedrux

Yes i am using a thermistor cartridge and I have this in my config.g:M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

-

What Duet board?

That looks correct for the E3D thermistor.

-

@Phaedrux

I am using a Duet 2 Maestro -

Are you sure it's PLA and not PLA+ or PETG?

Do you have another filament you can test with?

-

@Phaedrux

Im sure that it is regular Prusament PLA

I have some some old ABS laying around and i have tested it apart of some worping issues there were no problems.

I think the problem was just to low Temps and i just looked it up prusa Recomends 215°C so i guess 220°C is not way to hot for the filament. I Think in the prosses of trying to eliminate the problem i Just overlooked the Temp. I will try lowering temps and Print speed to figur out if the hotend just couldnt ceep up melting the material at that speed. -

So the other thing to consider that's often overlooked is what nozzle you're using. If you're using a steel/hardened/nozzle-x or similar, you will measurably compromise the energy transfer to your filament. If this is the case, it's entirely reasonable to need a temperature 10degrees or more than what's quoted for your filament.

I use an Olsson Ruby nozzle which is another special case. The body of the nozzle is made of two parts, so despite it being a brass nozzle I print pretty much all PLA at 210/215 degrees and can't achieve higher volumetric flow rates without a lot of fine tuning.