Magically changing feed amounts

-

My guess is that it's a mechanical issue caused by the back pressure from the nozzle and the extruder stepper motor heating up, which will cause the filament to soften especially if you are using PLA. How hot does the extruder motor get after an hour of printing? What extruder design and what motor is it?

-

yes i am now thinking you may be on to something did the update and tried slic3r cura is pants its just my oppinun dont shoot me

im using all metal Bowden Extruder out side of case i got a 1.7amp stepper motor running at 1.2amps

and it seems i can now not feed 100mm thought my extruder (e3d v6) with out the motor jumpingin case you want to see config file below

; Configuration file for Duet WiFi

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Sat Nov 19 2016 12:24:27 GMT+0000 (GMT Standard Time); General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates…

M83 ; ...but relative extruder moves

M555 P5 ; Set firmware compatibility to look like RepetierM667 S1 ; Select CoreXY mode

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X270 Y270 Z250 S0 ; Set axis maxima; Endstops

M574 X1 Y1 Z1 S0 ; Define active high microswitches

M558 P1 X0 Y0 Z0 H5 F120 T6000 ; Set Z probe type to unmodulated, the axes for which it is used and the probe + travel speeds

G31 P600 X0 Y0 Z2.5 ; Set Z probe trigger value, offset and trigger height; Drives

M569 P0 S0 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X79.5 Y79.5 Z400 E87.68 ; Set steps per mm

M566 X900 Y900 Z12 E120 ; Set maximum instantaneous speed changes (mm/min)

M203 X6000 Y6000 Z180 E1200 ; Set maximum speeds (mm/min)

M201 X500 Y20 Z250 E250 ; Set accelerations (mm/s^2)

M584 X0 Y1 Z2:4 E3

M906 X800 Y800 Z800 E1200

I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Heaters

M143 S260 ; Set maximum heater temperature to 300C

M305 P0 T100000 B4008 C0 R4700 L0 H0 ; Set thermistor + ADC parameters for heater 0

M305 P1 T100000 B4008 C0 R4700 L0 H0 ; Set thermistor + ADC parameters for heater 1; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Network

M550 Pduetwifi ; Set machine name

M551 Ptony ; Set password

M552 P0.0.0.0 S1 ; Enable network and acquire dynamic address via DHCP; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Custom settings are not configured

-

-

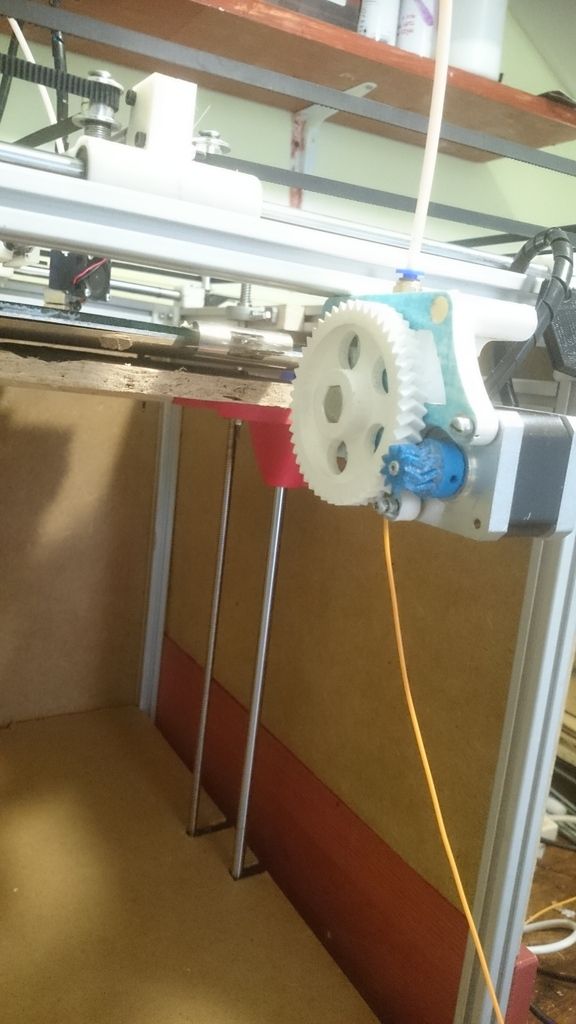

It looks to me from the photo that you are using an un-geared extruder. Those typically need a long, high-torque Nema 17 motor run close to its maximum current to deliver enough force, especially when printing PLA. So try increasing the current to 1.5A or 1.6A.

-

thanks for the tip ill look into geared bowden are better motor if you have found any you think are cool are work great please share

thanks for your help -

thanks for the tip ill look into geared bowden are better motor if you have found any you think are cool are work great please share

thanks for your helpIf you have the cash http://shop.bondtech.se/ec/extruders/bondtech-qr-175-universal.html

-

Ouch thanks for the link but it will cost me and extra in import tax I'll stuck with UK stuff

Are print something out -

Ouch thanks for the link but it will cost me and extra in import tax I'll stuck with UK stuff

Are print something outI recommend either the E3D Titan or the spring-loaded variation of the RapRap Ormerod extruder which is mostly printable. Both have a gear ratio of around 3:1.

-

I can't really tell from the pics but another possibility is that whatever drives the filament is slipping on the motor shaft. It's a quick check to make sure that the grub screws are all tight.

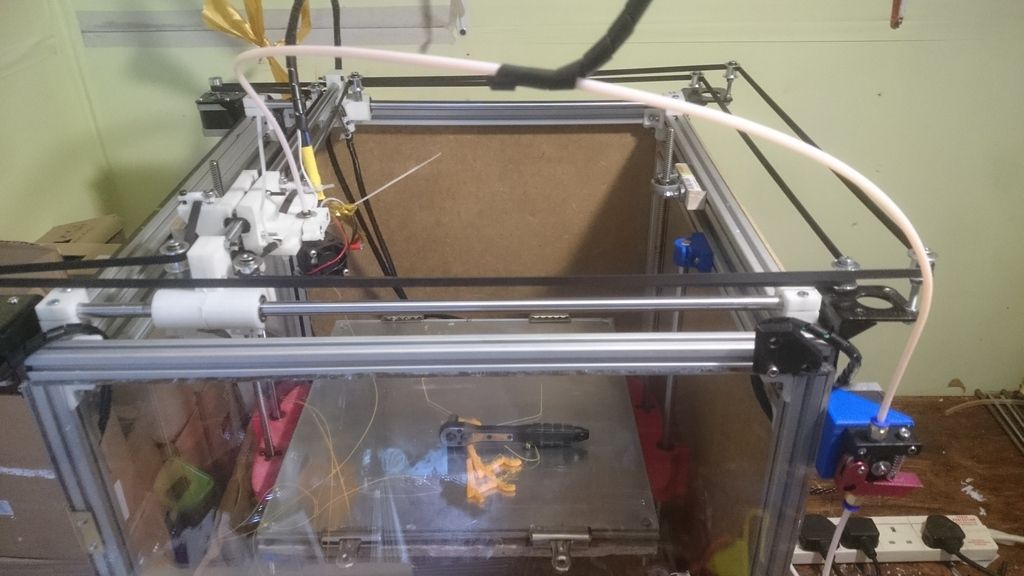

A little tip - with a bit more aluminium extrusion you could mount the extruder above the bed, roughly in the centre which will reduce the length of your Bowden tube to less than half what you have now which will help in all sorts of ways.

-

Thanks for the tip

-

yep you was right it was maniacal i retro fitted an old wades extruder its running upside down and back to front but now it works like a charm so now to find that ormerod extruder

thanks for all the help

of course i can not shut the door but ill fix that soon

-

OK the problem is still persisting on long prints my printer fails a couple of hours in but small prints.look much beter

Is it worth putting a fan over the duet board -

If it's a Duet WiFi, then with the motor currents set as low as you have them it is most unlikely that you need to cool it with a fan.

-

Untested yet! just sermizsing.

But I'll add a fan on board change the motor for one of the z motors

I also get strange things happen when I have motor wire crossed over and I thought I got good ones for Germany….

Never mind anyway I'll try all the above and make sure nothings come lose see if I can shorten my bowden tube

And I'll get back to you let youknow how I get on

p.s may take a few days

Thanks for all the help -

ok slight update not sure if this is related guess time will tell after a bit of head scratching wondering why nothing is working i found out i have a corrupt memory card pc is scanning and fixing is it worth retrying same card are just replacing it

p.s so happy i copied my setting to an earlier post -

hi all thanks for the help (dc42)

ok problemsmemory card stopped working ( replaced card sorted )

extruder getting hot and over extruding and under extruding and completely failing after 3 hoursturned out i had my blue wire ad snapped inside the sheaf …....while cheeking and rerunning all the wire it fell in half in my hand strange

its now 4 hours into a 6 hour print and back to normal

p.s i got an extra motor in the post now