Print Tolerance Tuning (Horizontal/XY Expansion)

-

Hello all,

Currently trying to tune the tolerances of my printer (custom Cartesian, 1.8 steppers, interpolated x256) on the XY plane. I have tuned the extrusion rate/flow percentage as well as the correct temperature settings for my filament (eSun PETG),

Does anyone here recommend additionally tuning horizontal expansion settings? That is a setting I haven't really payed much attention to, and I really want to avoid introducing finicky dimensioned offsets in my CAD models.

-

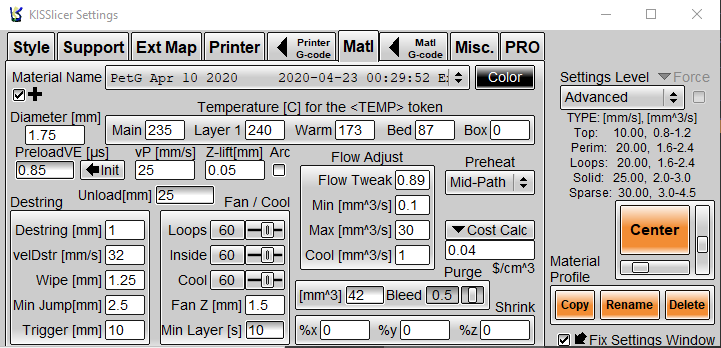

Depending on the slicer that you are using

If you are using Kisslicer in the material tab there is an area that you can use to adjust the shrinkage

If you are using simplify3d in the preferences other tab there is a spot to adjust for shrinkage it is called the dimensional adjustments

I am sure most of the other slicers have a similar area to adjust for shrinkage.

As a note I looked up the shrinkage factor for various plastics on the internet and used this as a starting point for the shrinkage factor for my slicers

I hope this helps -

You may want to check this thread https://forum.duet3d.com/topic/15212/how-to-compensate-for-x-y-dimensional-errors/11

The measurement described there suggests that on that printer, the error can be modeled as a combination of a fix offset (+0.2mm in that example) and a fix scale (x0.999).

So the question is where to compensate for those errors. There are several options. For example in the slicer, the offset can be compensate by x/y size compensation of -0.2/2=0.1mm and the scale by x/y/z scale of 1/0.999.

Note that the errors may change with material, temperature and other variables.

-

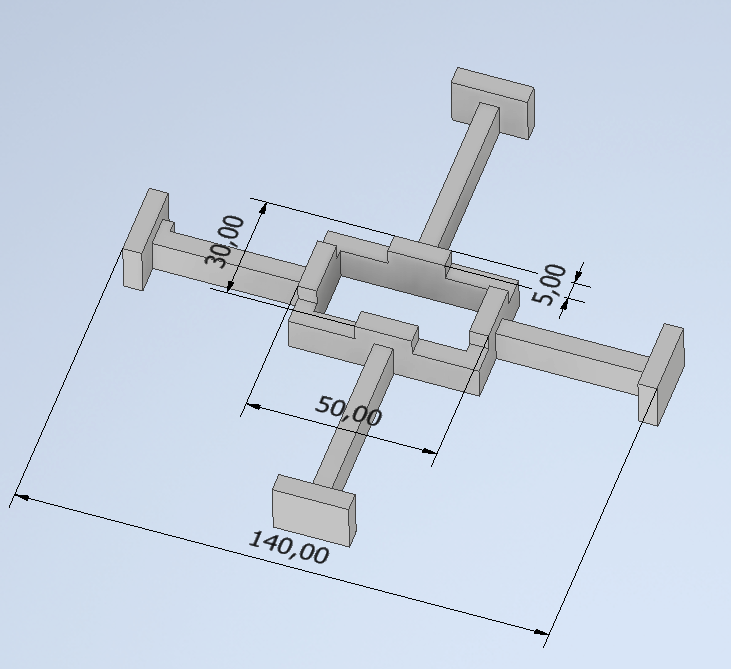

print largest square possible on your printer.

- you may leave center empty.

- on one side leave marking point (that will allow you to understand your axes)

make it 10 mm height

i use different figure (see below)

once you print it, measure X and Y sizes. calculate difference and scale factors as mentioned in post above

put adjustments in config.g with M579.

reboot. enjoy.