Blown driver

-

Drivers have that heat sink pad across their entire bottom... not what I'd recommend for someone's very first attempt at chip replacement, with so-so tools.

Of coursd, @Via it is your choice, if you are comfortable trying, go for it. At the same time, recognize that the board can be damaged in the attempt.

-

@bearer said in Blown driver:

TMC2660-PA

TMC2660-PA does not have a thermal pad which is why its possible to remove it without hot air. (and if the option is not repairing it no big deal)

-

@bearer said in Blown driver:

@Via said in Blown driver:

Duet 2 WiFi

You might be able to get some low temp solder (like quick chip (138C)) to remove the blown driver without needing a hot air station, but you'd want to pre-heat the whole board in any case (another printer with a 100+C hot bed maybe?). But yeah, the parts aren't free and quick chip adds up; the Duet3 also comes at a premium though.

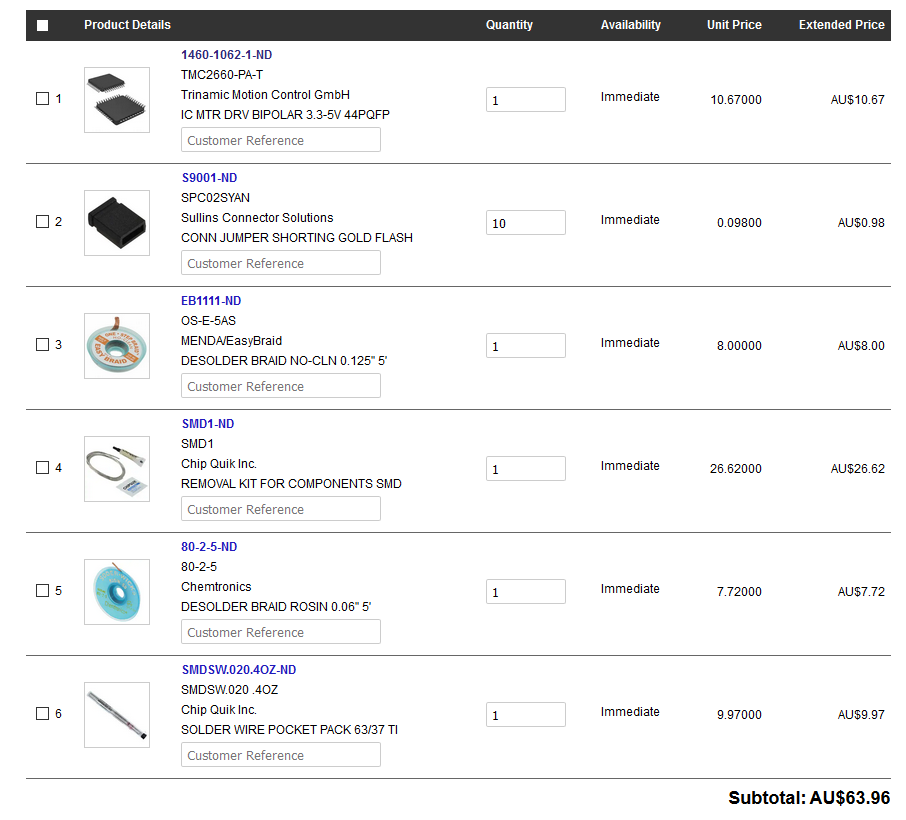

Just been doing the numbers on this myself. -

Getting "Driver 0 short to ground" after stupidly plugging a motor in without shutting off the power first.

The driver itself is cheap, but the associated bits add up.

Still, a new board is about five times that cost here is Oz, so I figure it's worth a shot.

-

@OwenD said in Blown driver:

but the associated bits add up

ChipQuick stuff is pricey, but you can get generic Bi58Sn42 solder or paste for a fraction of the price, same with solder wick. Shouldn't need two sizes for this job, I use 2mm for 95% as its a good fit for the medium tip I use for wicking. I wouln't skimp on the flux and solder though, and due to the 2oz copper thickness preheating the board is essential.

-

The most common reason for a driver to fail is that the stepper motor wires haven't been phased correctly.

-

@dc42 said in Blown driver:

The most common reason for a driver to fail is that the stepper motor wires haven't been phased correctly.

@dc42 I know there is a limit on how far you can productively "read backward" in a thread. In this case, the OP stated it was a wiring fault, connector plugged in "one pin off". So you are spot on, wiring, and the OP knows how to prevent it in the future.

-

Could that be made less fatal if turning the current right down to the minimum allowable until wiring is sorted out? But if you can't get a positive test without risking a failure then moot point i guess.

-

@dc42 said in Blown driver:

The most common reason for a driver to fail is that the stepper motor wires haven't been phased correctly.

Would that cause the driver to fail with a short to ground error?

It so, it would help explain how it happened.

I was changing an extruder and plugged the wrong motor into the X axis initially. The extruder I was replacing uses a different motor type.

When I got the short to ground error I assumed I must have forgot to shut down before I plugged a motor in, even though I was “sure” I had. -

I do have hot air station but only used to replace mosfets so I'm 50/50 if I will attempt to replace or just leave how is... in old printer (once I replace Z steppers).

Duet3 in the post for new one

-

@Via said in Blown driver:

50/50 if I will attempt to replace or just leave how is

If you have hot air and a 2nd printer whose hotbed you can use to preheat the board it shouldn't be too bad. The Z driver is a little extra tricky with less physical clearance around the chip, still possible to shield the surrounding parts but a vacuum pickup helps a lot to pick up the bust driver. On the other hand if you can re-purpose it as is then enjoy the Duet3:)