The Spice Must Flow sand table gets servomotors

-

I installed iHSV42-40-07-24 servomotors in my corexy sand table and have been running some tests. It's set for 10k acceleration, 2k speed, and IRIC 20k jerk. Peak speeds hit 2k, but of course, most of it is less than that because of all the direction changes.

I ran more tests at higher speed, jerk and acceleration settings, but the motors keep pulling the 200W supply voltage down causing the controller to reset. I need a bigger power supply!

I haven't tweaked any of the motor parameters in the integrated drivers yet- just running with factory defaults.

At some point I'll install these motors in UMMD and run some print tests.

-

@mrehorstdmd said in The Spice Must Flow sand table gets servomotors:

I installed iHSV42-40-07-24 servomotors in my corexy sand table and have been running some tests. It's set for 10k acceleration, 2k speed, and IRIC 20k jerk. Peak speeds hit 2k, but of course, most of it is less than that because of all the direction changes.

I ran more tests at higher speed, jerk and acceleration settings, but the motors keep pulling the 200W supply voltage down causing the controller to reset. I need a bigger power supply!

I haven't tweaked any of the motor parameters in the integrated drivers yet- just running with factory defaults.

At some point I'll install these motors in UMMD and run some print tests.

I'm surprised it doesn't throw the ball at those speeds. I've built a proto, that took about a year to have working pretty well, and am deciding when to build the "fine furniture" part...

Optical Endstops seemed to be one of the BIG keys to getting this basic design to work well.

-

@Danal The ball isn't on it - it would definitely leave it behind at these speeds, and if it didn't, it would throw the sand around and not make a nice pattern. I find peak speeds of about 500mm/sec works well with the ball size (12 mm) and sand (baking soda) depth (around 3-4 mm) I am using. I run erase patterns at 666 mm/sec and it throws the sand so it leaves the surface almost smooth except for the ends of each line at the far edges of the table. The problem with that is the top is too close to the sand and some of the thrown sand inevitably ends up stuck to the underside of the top, blocking the view of the pattern. The next version of the table will put the top higher above the sand so that doesn't happen.

It has optical endstops now... not sure what they have to do with getting it to work well- I was using clicky switches until yesterday and it worked fine. I was avoiding hitting the switches by running the patterns 5mm away from the edges with the endstops. Mostly I didn't like to hear them clicking so much, and they probably last longer when they aren't getting bumped 500 times per pattern. With the optical stops I don't have to worry about that.

-

Clicky would work well... I'd exactly copied the person with the hall effect stops. They are just a little to loosey goosey for exact centering of a SCARA.

Also, I don't have glass on mine yet, so take this with some limits... I am using "Hamster Bathing Sand". Seems to work very well. Amazon. It might stick less (or more, who knows). Thanks for the exact speeds, I'm still experimenting.

-

Smooth, quiet, fast... very nice!

-

@Danal What does the mechanism look like for a round table? I'm trying to make this thing run quietly and starting to think that I have to get rid of the ball bearings that turn at high speeds- they clatter! I may switch from corexy to a simpler mechanism that uses fewer pulleys. Also considering going to bronze bushings instead of ball bearing pulleys. I suspect they'll be quieter.

Hamster bathing sand! I hadn't heard that one before. I'm using sodium bicarbonate sand-blasting medium. I think the food grade stuff is finer, so might make for more detailed patterns. I'll switch to that when I have my final design (been working on this thing since 2018!) worked out.

Sandify has added a lot of new stuff recently, including minimizing table edge and corner movement that makes high loop-count patterns possible without having to watch the ball go round and round the edges of the table.

-

SCARA. The actual Sisyphus uses a sort of "bar on top of a rotary shaft" that certainly seems to work. I may convert over (back?) to that. But the SCARA seems to produce good patterns if you get it to "home" EXACTLY to the center (as defined by its own arms). And the opticals seem to make that work.

I haven't looked at Sandify in a few months; I'll give them some fresh attention.

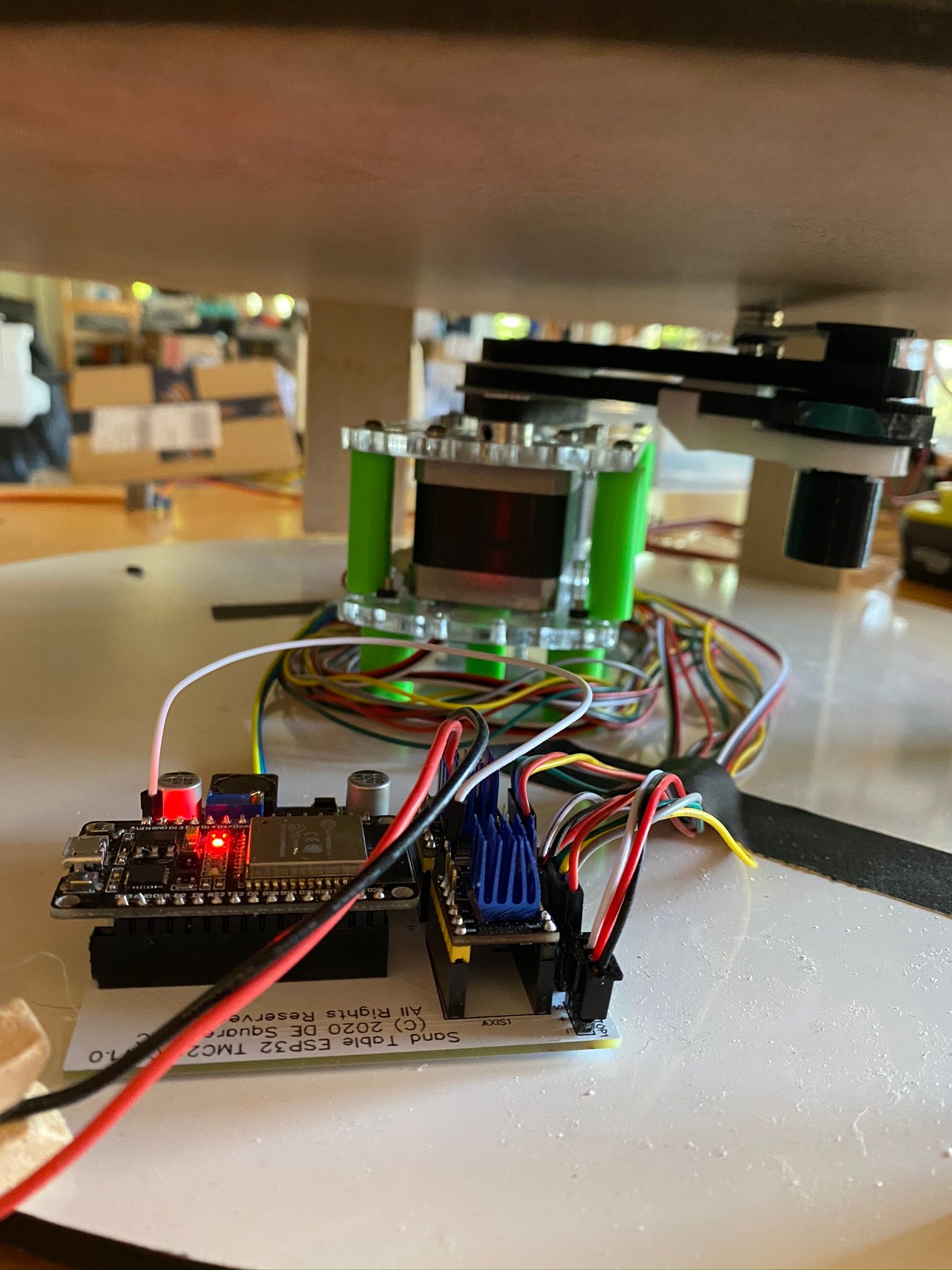

The pic of the mechanism is pretty bad, I was apparently trying to get the board. It may help to know the "elbow" of the SCARA is pointed almost at us, at the right edge of the pic. The wrist and hand are visible with magnets in the background.

Also, the rim LEDs need to be "Higher". (Proto...). Yada Yada.

-

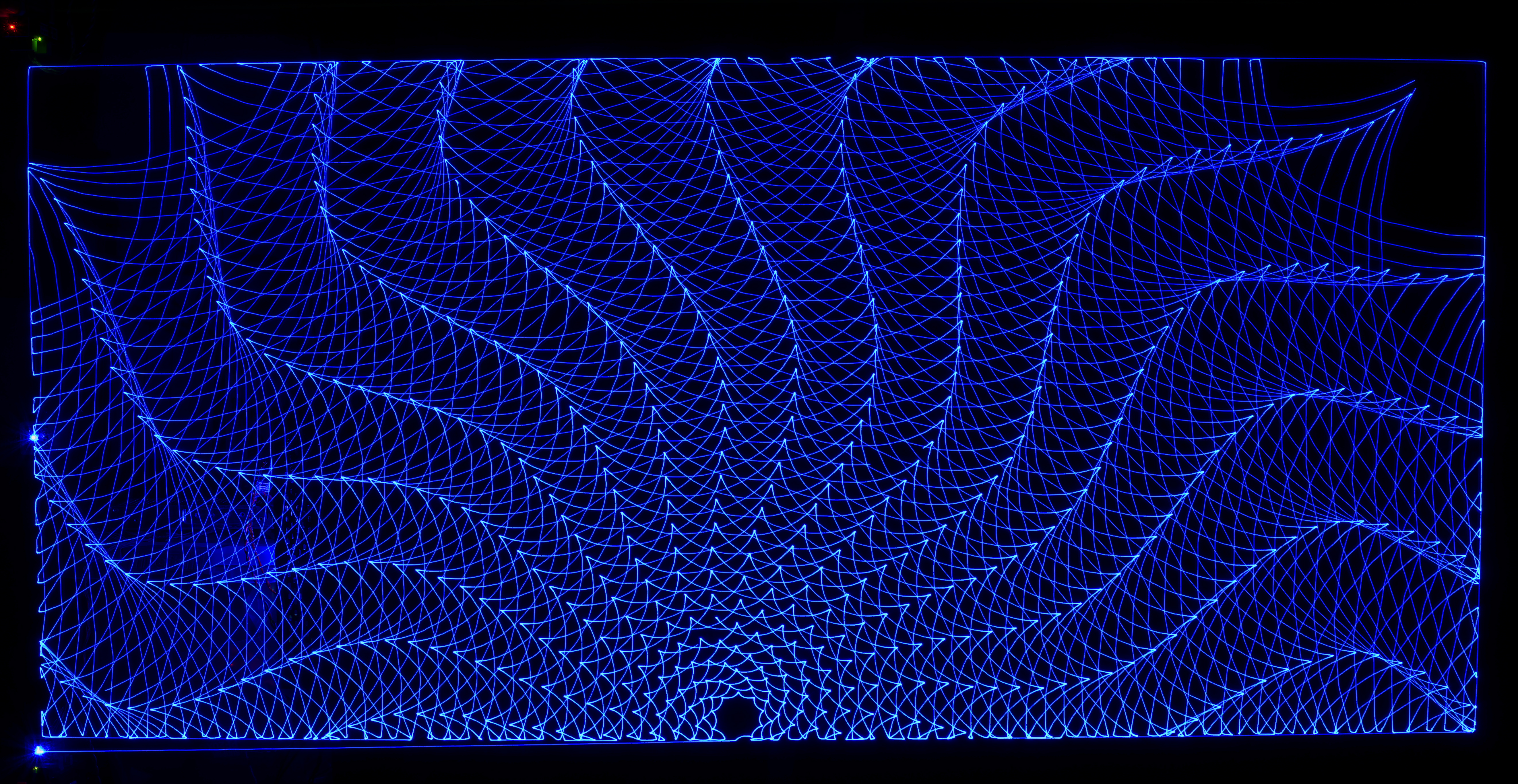

I put an LED and coin cell battery in the magnet holder, turned the table on its side, and ran a pattern. The result:

It took about 5 minutes with the speed at 2000, accel at 10k, and jerk at 12000.

-

I put the sandbox back on the table and ran some tests aimed at finding the upper limits of speed and acceleration for drawing patterns in the sand. I failed ... to find the limits!