Nozzle's Z-coordinate Up & Down when moving across X-axis?

-

I am using an FLSUN QQ-S Pro Delta printer w/ a Duet 2 Wifi board & a BLTouch, and whenever I attempt to move the nozzle across the X-axis, Z goes up when X+50, and down when X-50... But going from Y-50 and Y+50 has no issues. Any inputs appreciated!

config.g file:

G29 S1 ; enables mesh leveling

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet1" ; set printer name

M665 R142.212 L280.5 B120.0 H368.28300 X0 Y0 Z0 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 A+0.00 B+0.00 ; put your endstop adjustments here, or let auto calibration find them

; Network

M551 P"d00rst0p" ; set password

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S1 ; enable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X101.50 Y101.50 Z101.50 E540.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X600 Y600 Z600 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeoutM221 S73 D0 ; sets extrusion factor of extruder to 73 percent

; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"zprobe.in+zprobe.mod" H5 F600 T1500 ; set Z probe type to bltouch and the dive height + speeds(diveheight=H probingspeed=F meshbedspeed=T)

G31 P25 X0 Y45.5 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 R85 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 A12.4 C33.7 B1 D3.1 S1 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 A340 B0 C140 D5.5 S1.00 ; disable bang-bang mode for heater and set PWM limitM501

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned on; Tools

M563 P0 F0 S"Side Fans" ; define tool 0, uses extruder drive 0, heater1 and fan0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0CM563 P2 H1 S"J-head Heater";

M563 P1 D0 S"Extruder" ; creates tool 1 with extruder titled extrusion

T1; Custom settings are not defined

M302 ;yes

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power lossbed.g file:

M561 ; clear any bed transform

G28 ; home all towers

; Probe the bed at 3 peripheral and 3 halfway points, and perform 6-factor auto compensation

; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g.

G30 P0 X0 Y109.9 H0 Z-99999

G30 P1 X92.5 Y-64.95 H0 Z-99999

G30 P2 X-92.5 Y-64.95 H0 Z-99999

G30 P3 X0 Y64.9 H0 Z-99999

G30 P4 X56.21 Y-32.45 H0 Z-99999

G30 P5 X-56.21 Y-32.45 H0 Z-99999

G30 P6 X0 Y0 H0 Z-99999 S6

; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors

; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed) -

@Ubelherz said in Nozzle's Z-coordinate Up & Down when moving across X-axis?:

G29 S1 ; enables mesh leveling

First off, don't load the heightmap at boot up. Only load it after you've used the z probe to define where Z0 is. Loading it at startup can lead to some unintended z offsets. A good place to load it is in the slicer start gcode after Z0 has been defined by the probe using G30.

So for a delta...

G28 to home the towers

G32 to auto calibrate

G30 at the center of the bed

G29 S1 to load the heightmapThis also means that you may need to redo the heightmap.

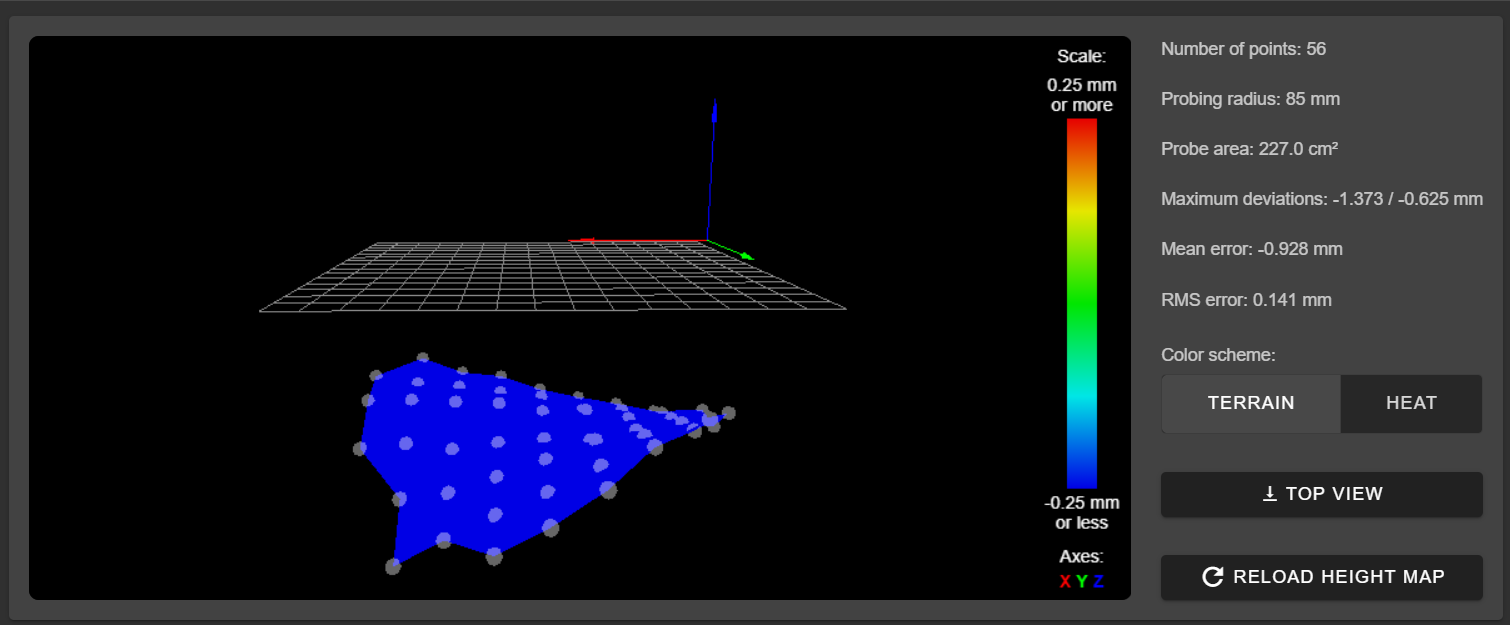

Also, moving the Z axis depending on bed position sounds a lot like the effects of mesh compensation. What does your heightmap look like? Does it match to how the nozzle is moving?

-

This is currently how it looks

It does in fact match up with the way the nozzle is moving*