Trying to understand coordinate systems...Add + Sub

-

I'm prepping to do subtractive operations on printed parts and I am curious about coordinate systems.

I'm assuming the XYZ placement of printed parts in my slicer are going to be different than the set origin in my CAM software (I want to use Fusion360). I guess both will use absolute coordinates, but how can I ensure they are aligned?

I hope you can forgive my ignorance! I appreciate any advice!

Platform is an E3D toolchanger..

-

...Actually, my thinking on this may be wrong. If my part is printed at (0,0) on the build plate, I will try setting the same origin in Fusion and report back with results.

-

If you set the stock size to the same dimensions as you can print, and set its origin to also be the same as what the Duet uses for its absolute coordinates (typically front left on the build platform), the 2 operations should align.

-

@Jacotheron Finally had a chance to test this with Fusion 360 and it is working for milling. Thank you!

-

This is awesome. I’m working my way to this slowly with my toolchanger. So I understand correctly, you used the same coordinates for the CAM operation as where the part was printed?

Did you just rely on the printed part staying adhered to the build plate? Or did you secure it in some fashion?

-

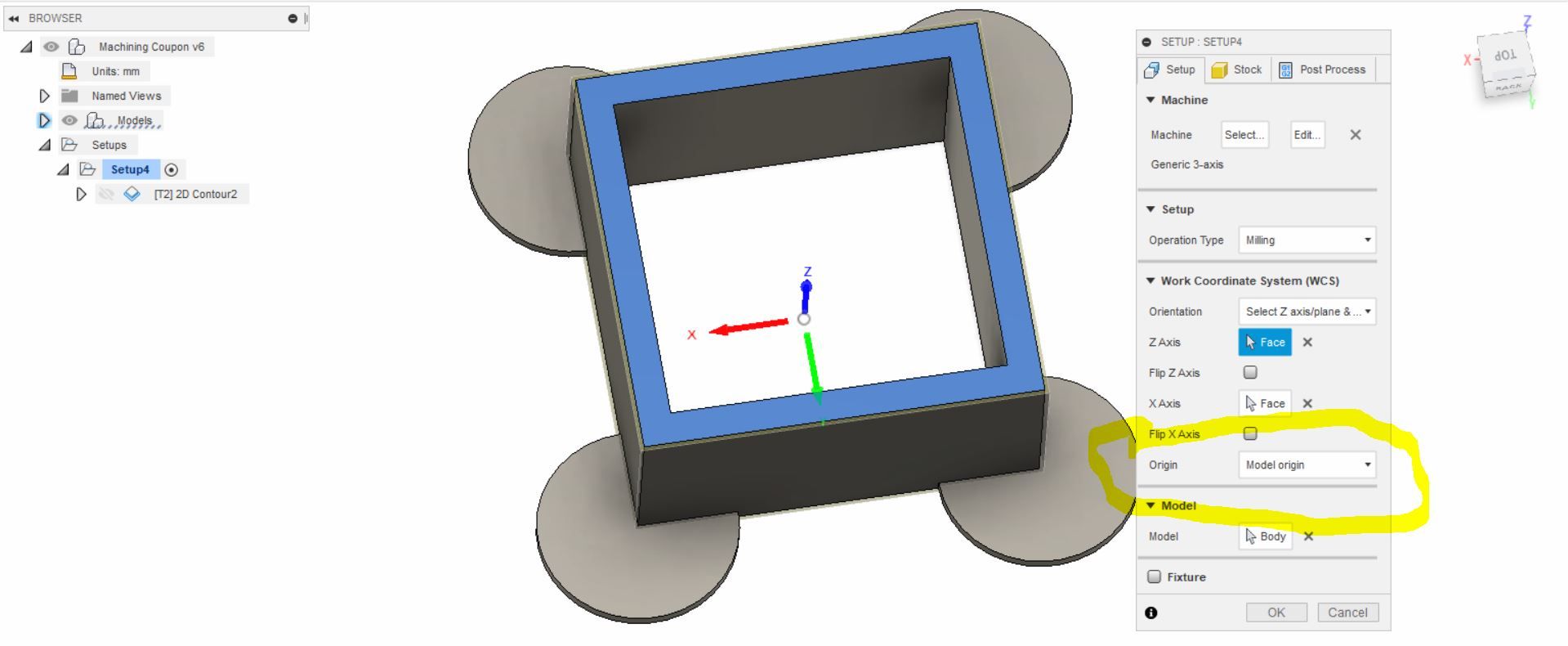

@mikep419 In this case, I designed the part in F360 with respect to the origin. Then, In the F360 manufacturing module, you can select "Model Origin" in the Setup menu.

Then I take the model into my slicer (Prusa Slicer) and ensure that it is centered on the build plate.

For more complex designs, multiple objects, or objects designed away from the origin, I will have to think about how this will work. But maybe I am over-thinking it.

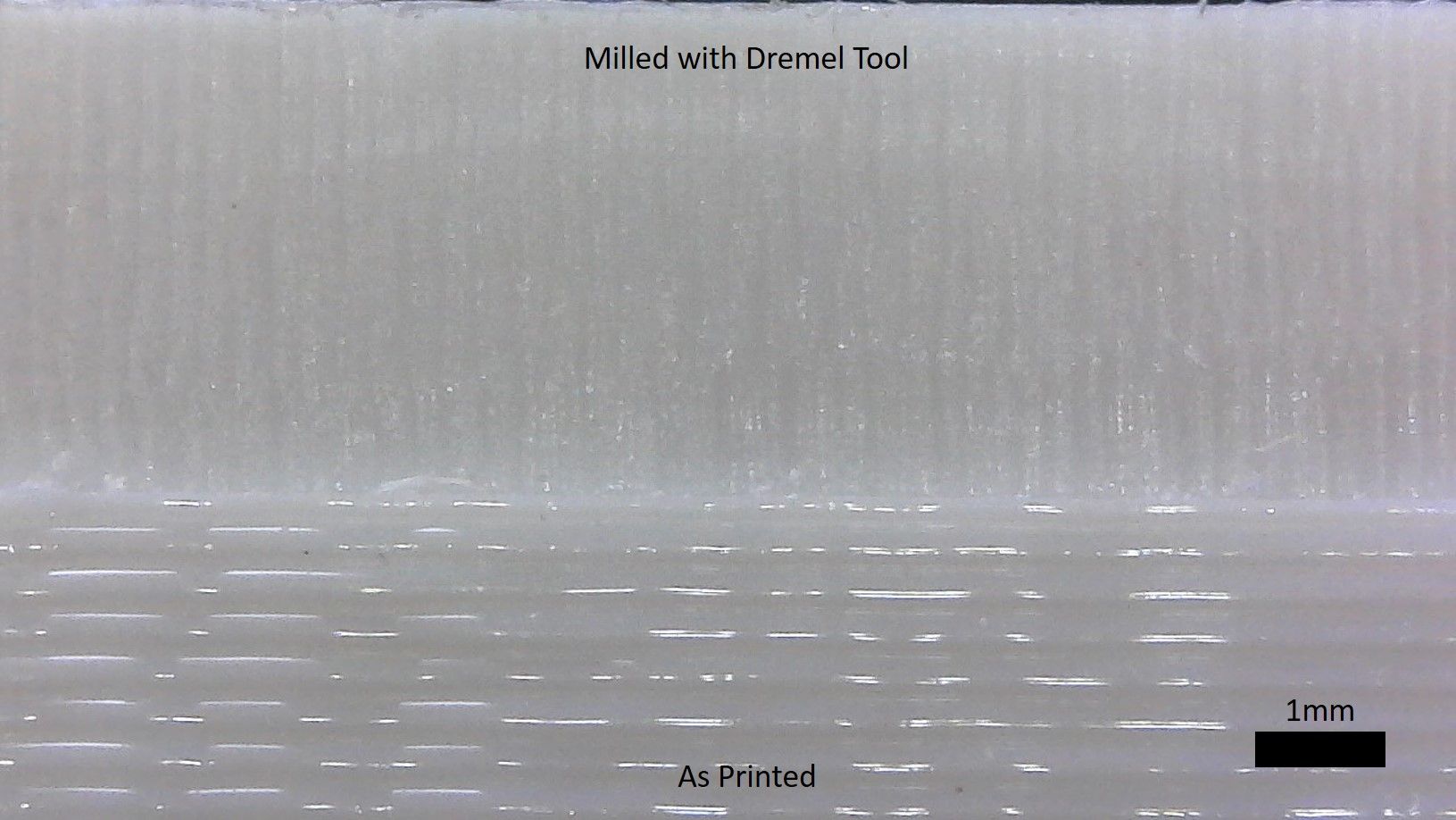

Yes, after printing, I kept the bed heated to maintain adhesion (PETG + Garolite Bed @70C). I am taking very small machining passes, and I haven't yet run into issues.

-

@jpomo10 said in Trying to understand coordinate systems...Add + Sub:

Then I take the model into my slicer (Prusa Slicer) and ensure that it is centered on the build plate.

Have you tried the F360 slicer yet? I'd think it should be pretty well integrated for this?

-

@Phaedrux I had the thought of using F360 for fully integrating CAM and Addative but haven’t dug into using it for slicing for the TC. Stupid work is always getting in the way of my hobbies. That would be the ultimate goal with the TC though. Print the model change tools and machine... Think I’ll use some of the 100sqft of garolite the power company left for me at work to make some sacrificial beds so I don’t machine some nice grooves into my print bed as I start this journey.

-

@Phaedrux Not yet! I had heard it was still in a nascent stage, but I'll look into it more in the future as it is updated.