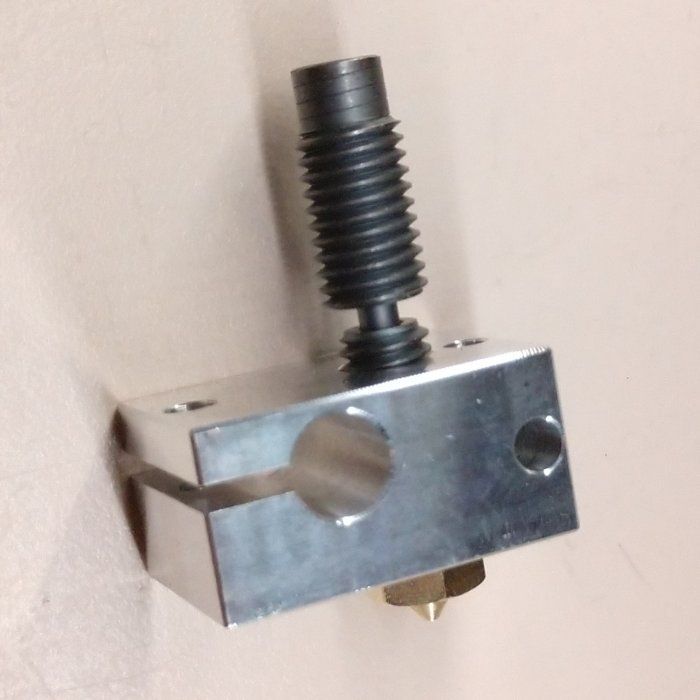

Slice RepRap Heat Break in E3Dv6

-

Has anyone tried using the RepRap version of the Slice Copperhead heat break in an E3Dv6? Mine just came. Apparently the Copperhead heater block has a longer threaded section than E3D. It sticks out a bit, but I'm going to to grease it with boron nitride and try it anyway.

-

Interesting experiment, let us know what you think of the outcome.

Also, you might want to distribute the excess a bit by having the nozzle stick out a bit further than it would in an E3D setup.

I am assuming that you are trying this to improve heat break performance ? -

@jens55 said in Slice RepRap Heat Break in E3Dv6:

I am assuming that you are trying this to improve heat break performance ?

Pretty much this. With the previous hotend I had problems with re-extrusion after retraction. It was one of the early E3Dv6 models, and I know some of those had issues. Maybe a new standard heat break would be fine, but I wanted to give the bi-metal one a try. The boron nitride is still drying, but I'll run some PLA through it this weekend and report.

-

Could you explain 're-extrusion' please?

I use a Volcano hot end and even if I retract the filament, the material that is in the melt zone will slowly oooze out of the nozzle. Is that what you describe as 're-extrusion'?

-

When the printer retracts to make a rapid travel move, it then has to un-retract before it can keep putting down plastic. By re-extrusion, I guess what I really mean is the un-retraction event and the extrusion immediately after.

I found that after the un-retraction, it would often take some time for the plastic to start flowing again, but the printer would already be started on the perimeter or whatever. This would tend to leave gaps and thin spots. The problem was worse with PLA, as you would expect with heat creep.

-

Ah, thanks for explaining. Yes, I have seen that too. I use pressure advance to combat this issue. If the nozzle has drooled a bit, all bets are off