Motor / drivetrain vibration reduction

-

Hi All,

This is a curiosity post – asking for other’s feedback on their experiences - not because I have a hard problem or such with any of the systems or symptoms mentioned, but more for my knowledge as well as others whom may stumble across this post.

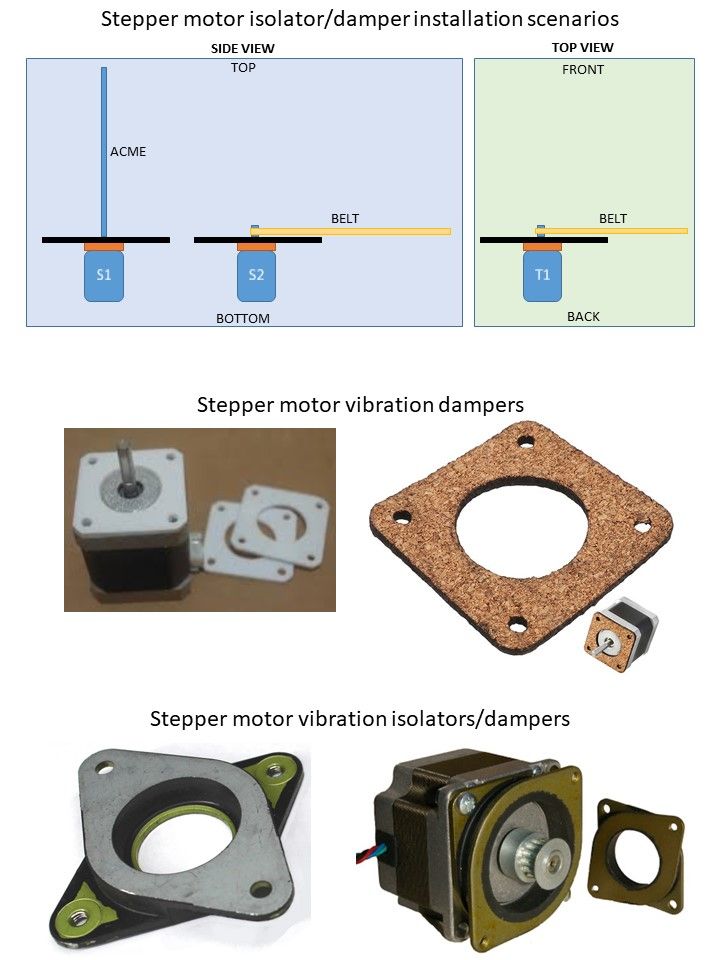

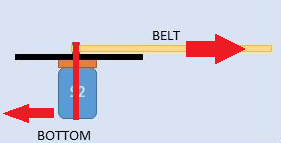

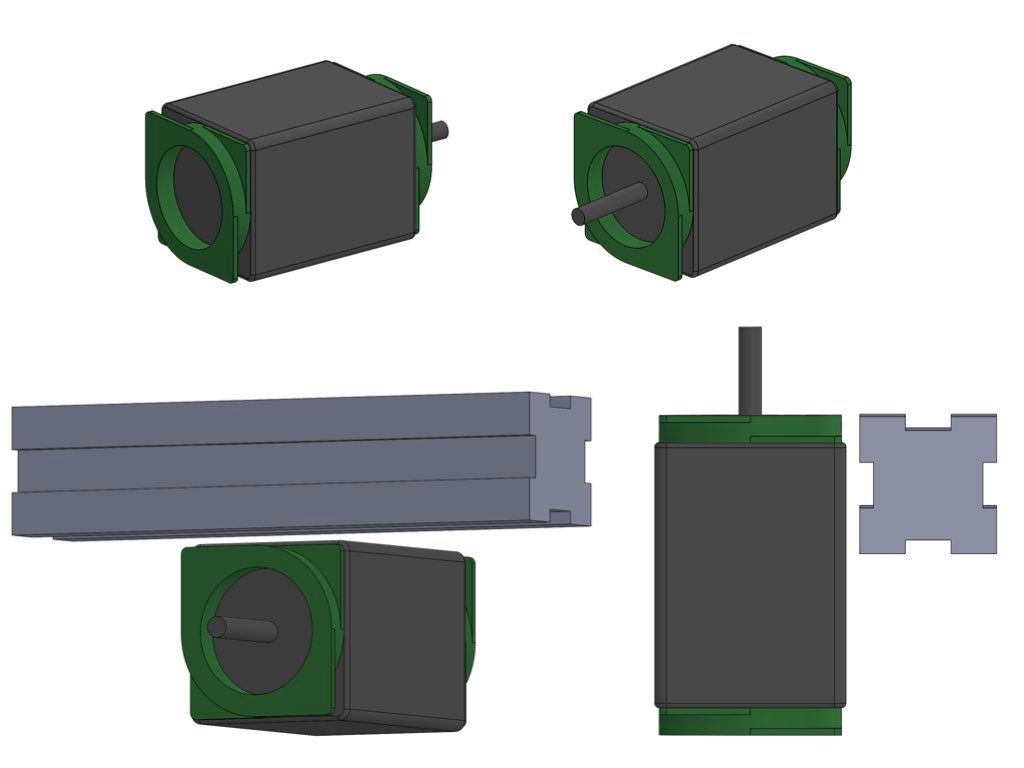

As I look into different ways to reduce stepper motor originated vibrations, and noise, I primarily see two options. The first being a compressible damping material sandwiched between the motor and mount, and the second being an isolator with a flexible material used as a stabilizer.

Taking a 3d printer’s needs out of the equation for a minute, it would seem that by each solution’s physical properties that the isolator would be best used in a horizontal plane where it suspends the motor as it hangs down [S1 example], to equal the forces through the membrane. While the vibration dampers, such as cork, would be best in all other options [S2, T1 examples].

What has been the actual performance and findings of the isolator mount used in scenarios as S2 and T1? It would seem that without the adjacent/opposite face of the motor being supported that it would cause dimensional error and excessive fatigue - this would be very obvious in T1, where the motor is hanging from its side and to a lesser extend in S2 where the motor is hanging straight down but being pulled to the side from the belt. It also seems that very few, if any, come with the manufacture’s specs for such, hardness, membrane composition details, loading, ….

I would like to know what your experiences with these solutions, or others, has been.

designing-quiet-vibration-free-operation.pdf

https://blog.orientalmotor.com/minimizing-stepper-motor-vibrationMany thanks!

Cheers,

Kolbi -

The rubber damper are actually quite rigid. I highly doubt there would be any sag from the minimal weight of a NEMA17.

For what it's worth the cork pads do make a difference and might be enough if your vibration issues aren't very severe.

-

Thanks @Phaedrux, the vibrations on my printer are minimal and of no real immediate concern. With that said, of course the quieter, and smoother, the better. For mine use I will most likely go with a damping solution similar to the cork pad offering.

I have used many sound/vibration isolation solutions over the years, they are critical onboard submarines and other sof platforms. For that I can admit that mounting a motor 'side-ways' with the isolation mounts shown above doesn't feel right - unless the motor had additional support to stabilize it or if the motor was to be mounted straight-down as [S1] in the figure above shows.

Maybe I'll get a set to play with, but hopefully some others can chime in with their experiences with those sorts.Cheers,

Kolbi -

@Kolbi From own experience with the rubber isolation rings I can attest that they are more than rigid enough so that motor orientation is of no concern whatsoever. At least for sizes that I worked with (nema 17 and recently 23). What might be more of an issue is load tangential to the motor axis. About a year ago I actually removed these style isolation rings from my printer as my (high) belt tensions would cause the assembly to flex out of alignment. In recent months I circumvented this issue by adding an extra bearing to the stepper shaft, opposite of the pulley.

There style dampers are excellent at what they do however. Due to the fact that is no other path for vibrations to travel from the motor to a motor mount (except for through the shaft, but you can't everything rubber right

). The cock pads are in my experience worthless for that same reason. No matter how ideal there vibration absorption characteristics are, there will always be a direct path to the motor mount via the bolts.

). The cock pads are in my experience worthless for that same reason. No matter how ideal there vibration absorption characteristics are, there will always be a direct path to the motor mount via the bolts.The following threads that I started might all be of interest for you. Keep in mind most of these are quite long (and not always a pleasant read

)and still ongoing.

)and still ongoing.

https://forum.duet3d.com/topic/14674/external-bearings-for-stepper-shafts

https://forum.duet3d.com/topic/17513/to-rigidify-or-not-to-rigidify-vibration-issues

https://forum.duet3d.com/topic/17725/building-a-sound-dampening-enclosure -

Thanks much for the insight @Nxt-1! So if I follow correctly, you had no observable issue with the motor + isolator mounted orientation but you did have a problem with the isolator flexing during high jerk belt movements causing alignment issues?

-

@Phaedrux said in Motor / drivetrain vibration reduction:

cork pads

@Phaedrux Did you intentionally pay closer attention to the motor mounting screws torque while using these damper pads? I would think there is a 'sweet-spot', whereas too loose and the motor could move, and too tight would compress the damping material to the point of 'uselessness'?

-

@Kolbi said in Motor / drivetrain vibration reduction:

Thanks much for the insight @Nxt-1! So if I follow correctly, you had no observable issue with the motor + isolator mounted orientation but you did have a problem with the isolator flexing during high jerk belt movements causing alignment issues?

Correct, the weight of a motor is quite insignificant compared to the other forces, like belt tension. The problem I had was not during high jerk movements, it was at all times. Even when the printer was powered off, the mount was flexing due to the belt tension.

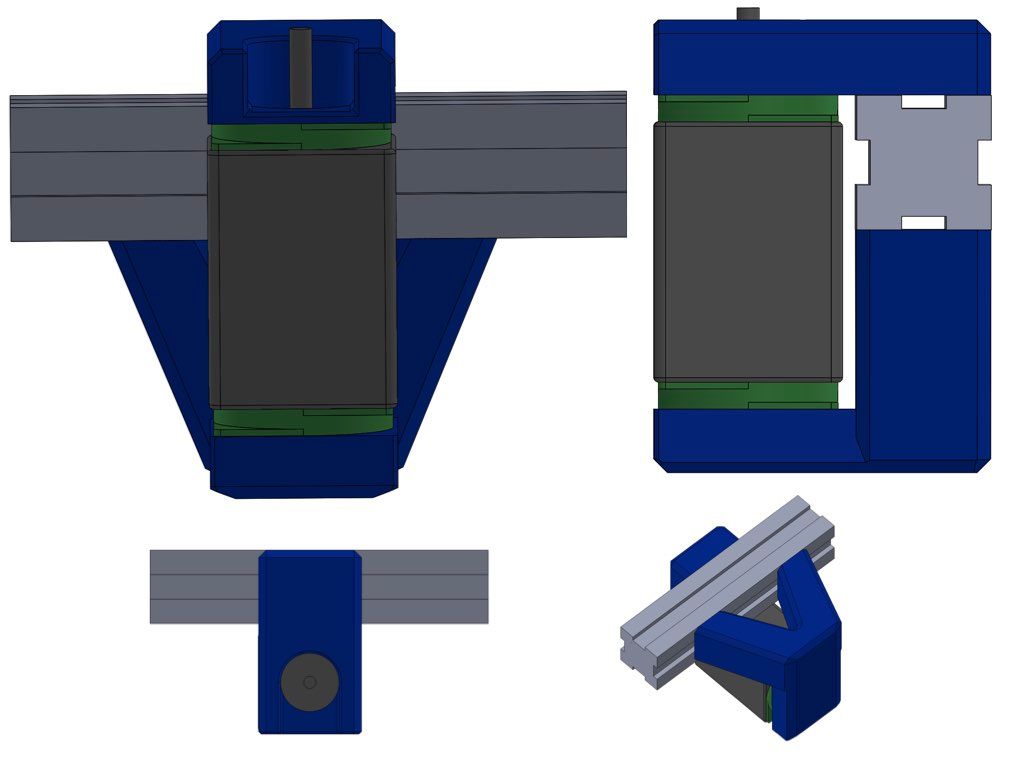

Shamelessly copying your image and some mad paint skills illustrates why. The force caused by the belt tension have to be compensated for one way or another. As the isolators are designed to be somewhat flexible, they flex. This happens no mater what the printer is doing. This effect of course gets worse as the pulley sits further from the face of the motor.

These dampers are relatively inexpensive, so you can always try them out with the belt tensions you are running and see how they work with your setup. If you deem they flex to much, you can remove them again. Or go the fun route and design a solution around it, like adding bearing.

-

@Kolbi said in Motor / drivetrain vibration reduction:

@Phaedrux said in Motor / drivetrain vibration reduction:

cork pads

@Phaedrux Did you intentionally pay closer attention to the motor mounting screws torque while using these damper pads? I would think there is a 'sweet-spot', whereas too loose and the motor could move, and too tight would compress the damping material to the point of 'uselessness'?

In my case the motor mounts were printed, so I didn't want to torque them down too much anyway, but I was still able to get it firmly hand tight.

One thing to keep in mind is that the cork does compress over time and you may need to retighten occasionally.

-

@Nxt-1 thanks much for clarifying - that was one of my concerns. The geometry you attached is similar to my Y, I do not have room to place a bearing as you did, but I am thinking in such a scenario of attaching a second isolator to the 'ass-end' of the motor may help stabilize and counteract the belt movement. It would be way cool if the manufactures of these items actually gave specs such as hardness, or maybe even different colored ones that readily indicate such. Even the isolators made by moons have no data but dimensional drawings...

I did send them a request for information, curious to see what I get in response.@Phaedrux thanks for heads-up on the cork compression. I'll have to check what the cork hardness is and see if I have any composites onhand that are similar.

-

@Kolbi said in Motor / drivetrain vibration reduction:

@Nxt-1 thanks much for clarifying - that was one of my concerns. The geometry you attached is similar to my Y, I do not have room to place a bearing as you did, but I am thinking in such a scenario of attaching a second isolator to the 'ass-end' of the motor may help stabilize and counteract the belt movement. It would be way cool if the manufactures of these items actually gave specs such as hardness, or maybe even different colored ones that readily indicate such. Even the isolators made by moons have no data but dimensional drawings...

I did send them a request for information, curious to see what I get in response.I think a second isolator is an excellent and creative idea, it never even crossed my mind. It seems plausible to me that it will remain effective at isolating vibrations and combat the static flex issue quite well. I'd love to see you implement it.

You might run into a practical mounting issue though. Due to how you bolt them to the stepper face and motor mount, bolting one to the backside you might find it hard to get a screw drive in a position where you can tighten the bolts. You'll have to make a drawing or experiment with that.

Finally some more shameless self promotion

I started a 3rd thread on the topic. I am still writing it so you will have to wait a while until there really is anything there https://forum.duet3d.com/topic/18281/battling-sources-of-vibration-and-noise

I started a 3rd thread on the topic. I am still writing it so you will have to wait a while until there really is anything there https://forum.duet3d.com/topic/18281/battling-sources-of-vibration-and-noise -

@Nxt-1, Well it's Friday here and we are still in 'covid lockdown' so once I'm out of work I draw something up in solidworks - shouldn't be difficult. I'll post what I come up with.

-

@Nxt-1 said in Motor / drivetrain vibration reduction:

see you implement it.

This was a quick go at it, but something close to the following. For perspective, I used a 3mm gap between motor and adjacent the surfaces, the width of this motor mount was 6mm.

-

@Kolbi Did you end up using the dual damper idea?

-

@Nxt-1 Hehe, currently I have all the required hardware on-hand but my workload picked up and I haven't had the chance to mess around with it.

With that being said, the printer has been getting used often and the print quality has been fantastic, so I'm a little hesitant(scared) to modify it at the moment. I'll probably get it done during the upcoming holiday break, fingers crossed.